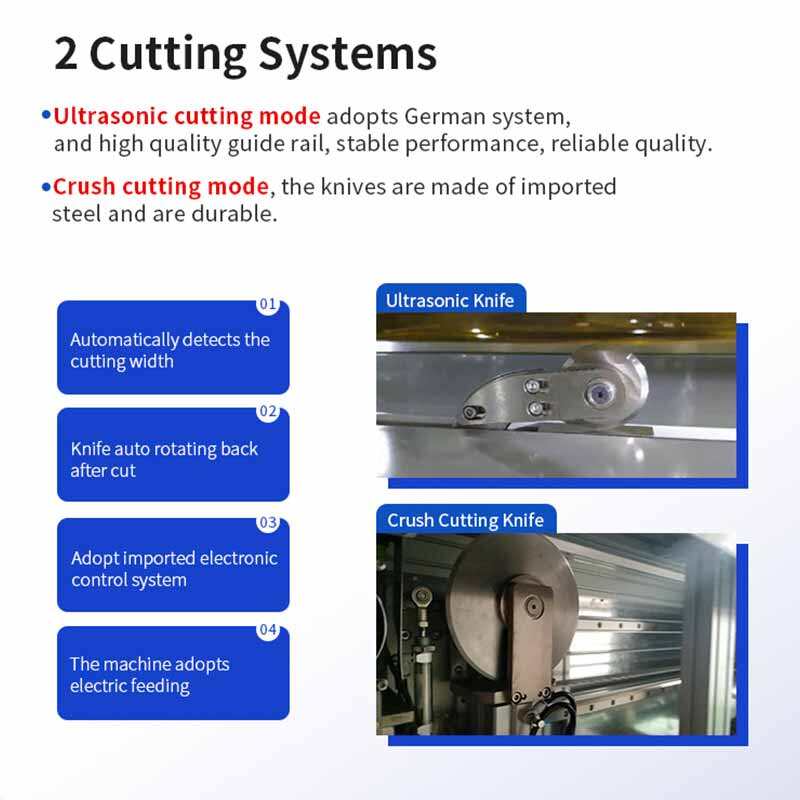

Dongguan Ridong Intelligent Equipment Co., Ltd. offers a top - of - the - line blind cutting table for sale, which is a perfect blend of quality, functionality, and affordability. This cutting table is constructed using high - grade materials and advanced manufacturing techniques, ensuring its durability and long - term performance. It features a spacious and sturdy work surface that can accommodate various sizes of blind materials, from small - scale custom projects to large - volume production runs. The cutting table is equipped with a high - precision cutting system that can handle different types of blind materials, including fabric, vinyl, wood, aluminum, and composite materials. The adjustable cutting guides and rulers on the table allow for accurate measurement and positioning of the materials, ensuring precise cuts every time. The blind cutting table for sale also comes with an optional automatic feeding system, which can significantly increase production efficiency by reducing manual handling and minimizing the risk of human error. The machine's control panel is user - friendly and intuitive, with clear instructions and settings that make it easy for operators of all skill levels to use. Moreover, the company provides comprehensive after - sales support, including installation, maintenance, and technical training, ensuring that customers can make the most of their investment. With its combination of high - quality construction, advanced features, and excellent customer service, this blind cutting table is an excellent choice for both new entrants and established players in the blind manufacturing industry. It enables businesses to produce high - quality blind products efficiently, reduce production costs, and improve their overall competitiveness in the market.