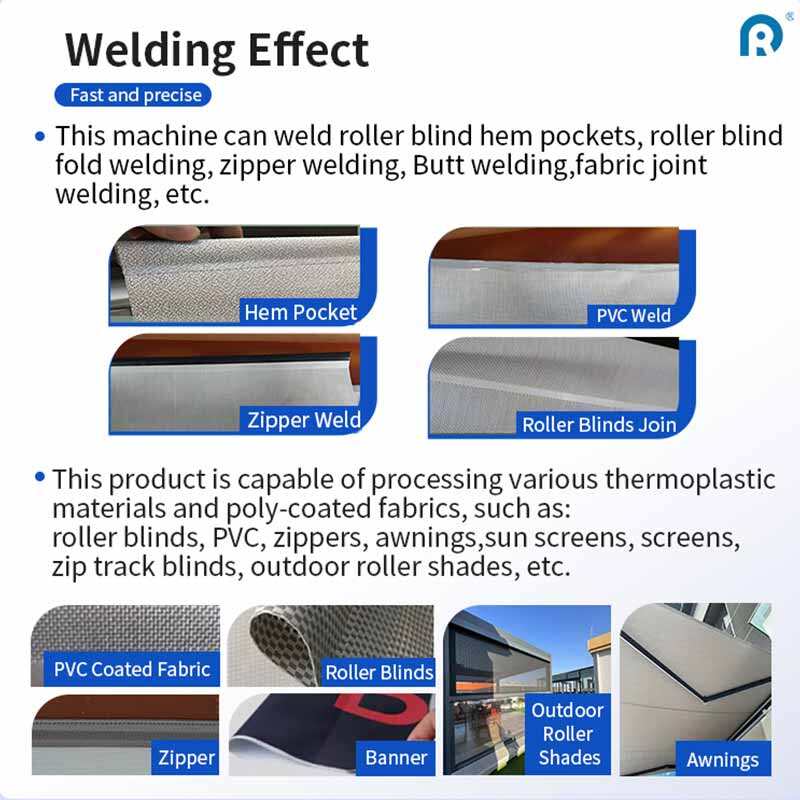

A cloth welding machine joins different cloth materials using Ultrasound or Thermal welding, sewing less and ensuring more durable seams. Cleavage styles are gentler on silk and lace fabrics with Ultrasonic welders, while thicker materials and plastics are expertly bonded with Thermal welders. It is suited for curtain, tablecloth, and upholstery manufacturing where clear edges and decorative stitching are required. Its capability to multi-layer and complex shape cut makes it a crucial component in artisanal and commercial workshops.