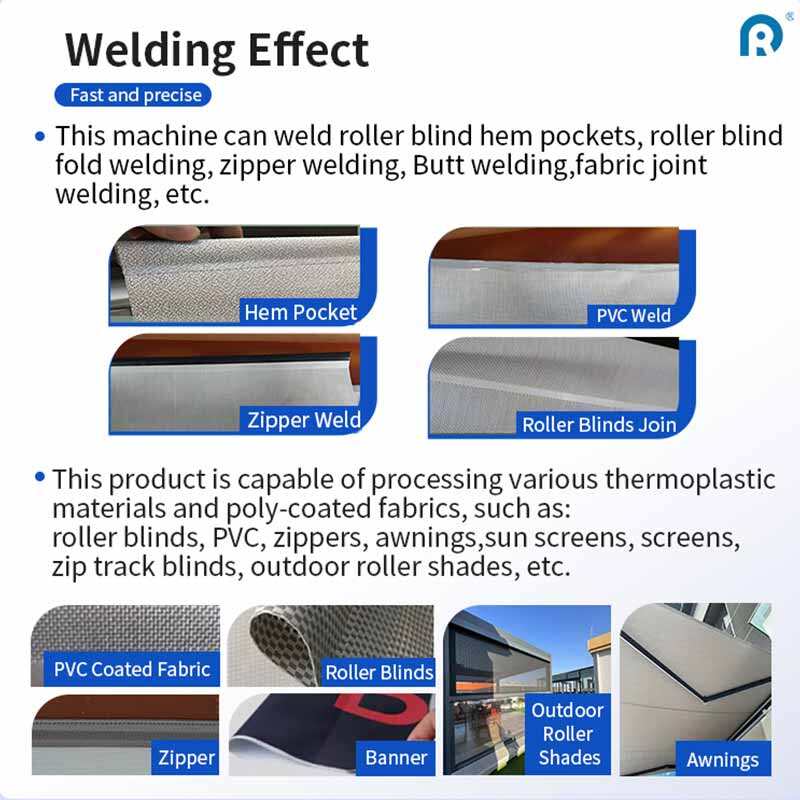

A fabric welder can be a compact or industrial device which uses heat, pressure, or ultra sonic vibrations to bind fabric layers together. Ultrasonic welders are popular among fabric welders for their speed and precision, ideal for synthetic fabrics, while heat welders are more suitable for PVC or EVA materials. These tools are used in producing curtains, awnings, and technical textiles and offer an advantage of reduced labor costs, material waste, and increased water resistance. For small and on-site repair projects, portable models are more convenient, while industrial versions are good for mass production.