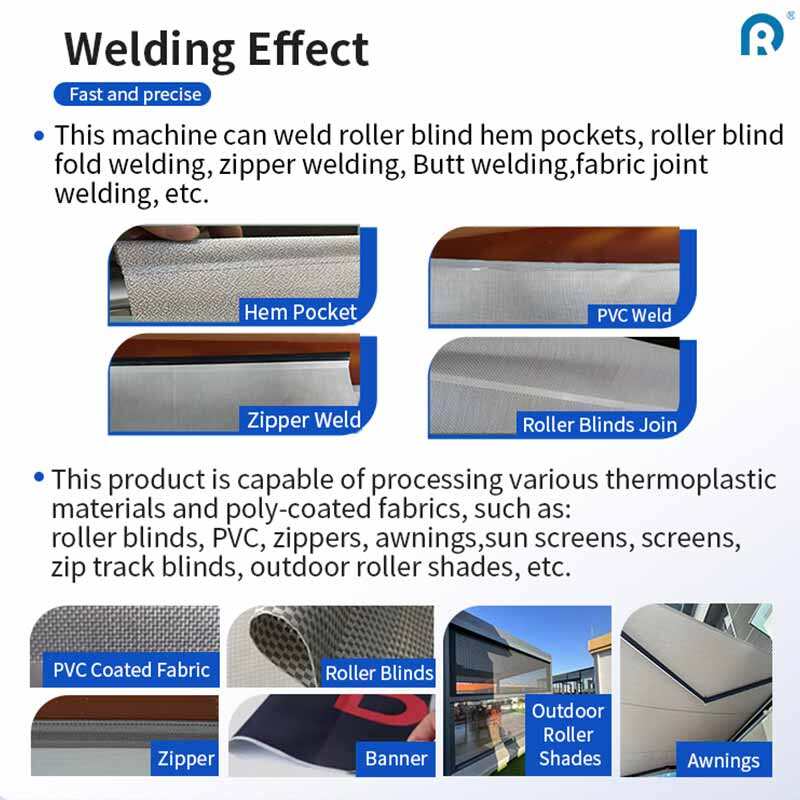

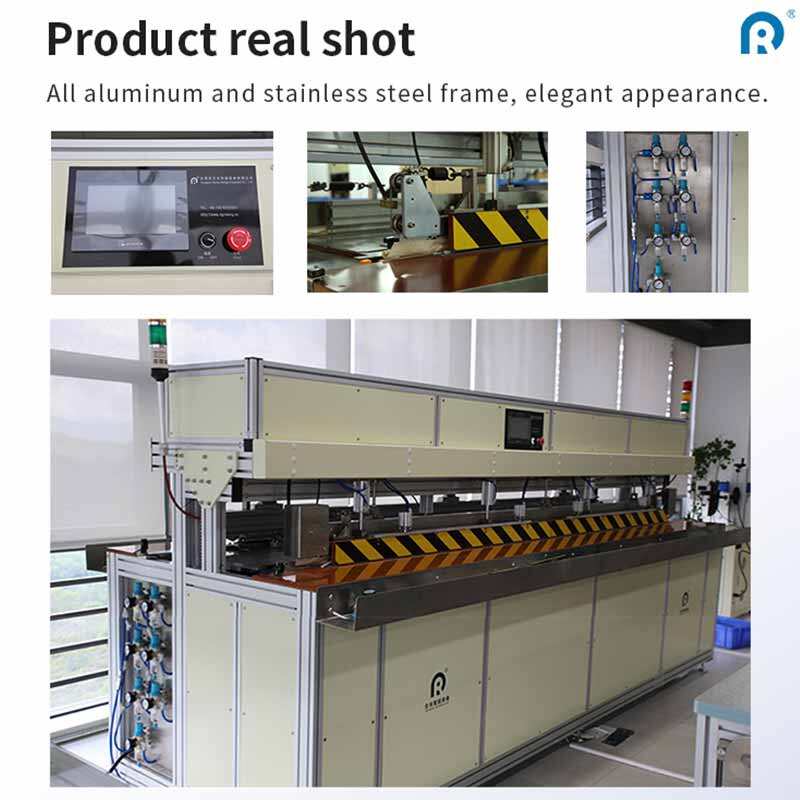

A roller blind welding machine allows for fast and efficient joining of roller blind materials. Unlike sewing, this method offers a quicker and more reliable bond. The machine supports blind materials composed of PVC, polyester, and composite fabrics. These are bound together using ultrasonic vibrations or heat to create strong and waterproof bonds. It is ideal for large-scale production due to its precision adjustable weld length, automatic material alignment, multi-layer processing, and other advanced features. The machine guarantees optimal durability and lowered labor expenses without compromising quality for indoor and outdoor blinds.