Curtain Setting Machine: Cost-Effective Solutions for Small Factories

Understanding Curtain Setting Machines for Small-Scale Production

What is a Curtain Setting Machine?

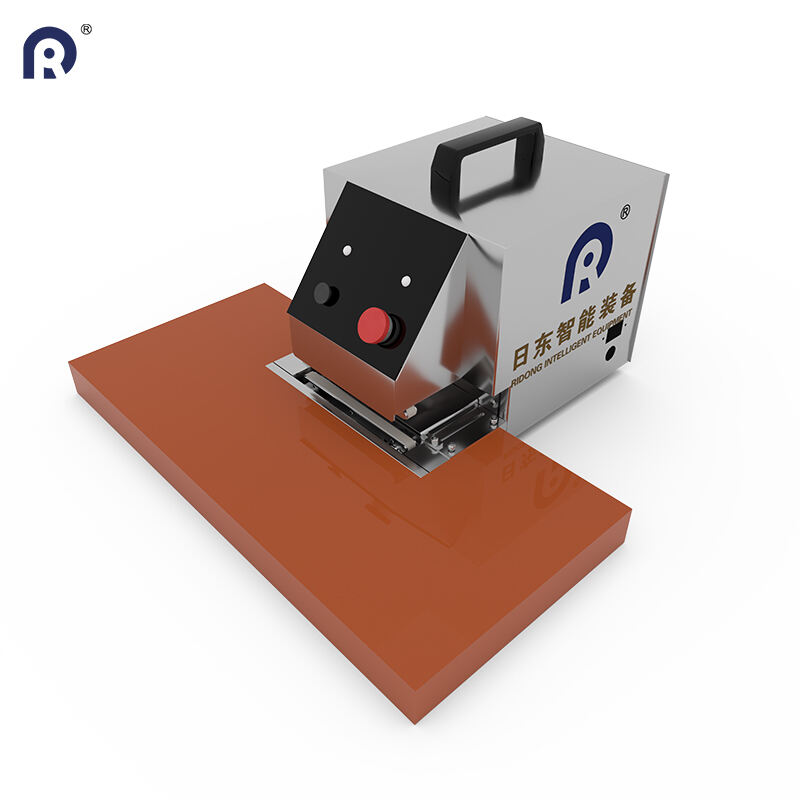

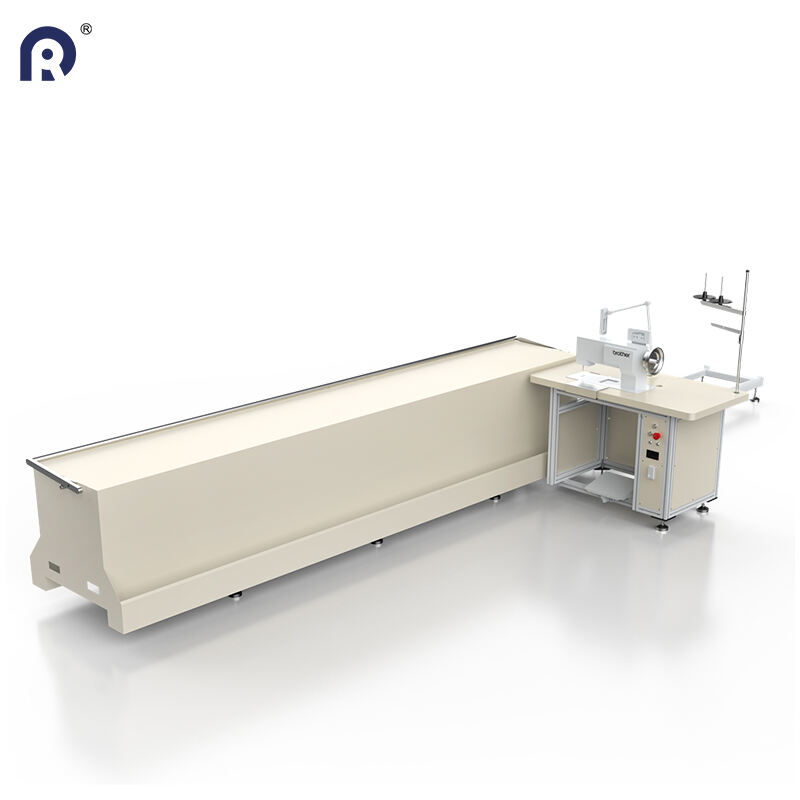

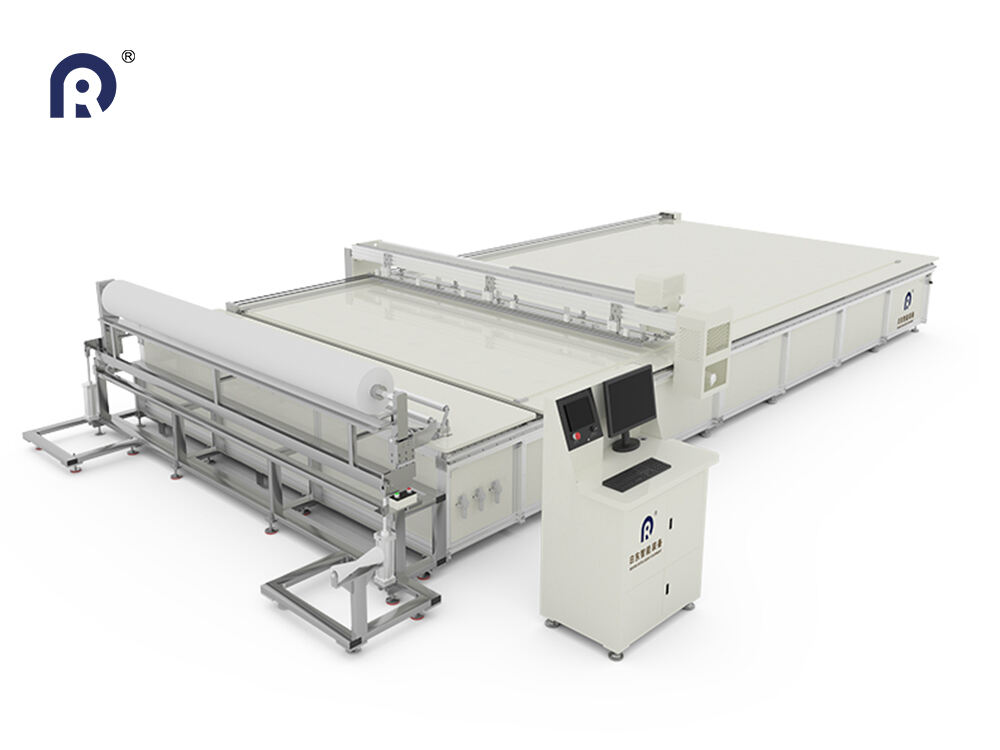

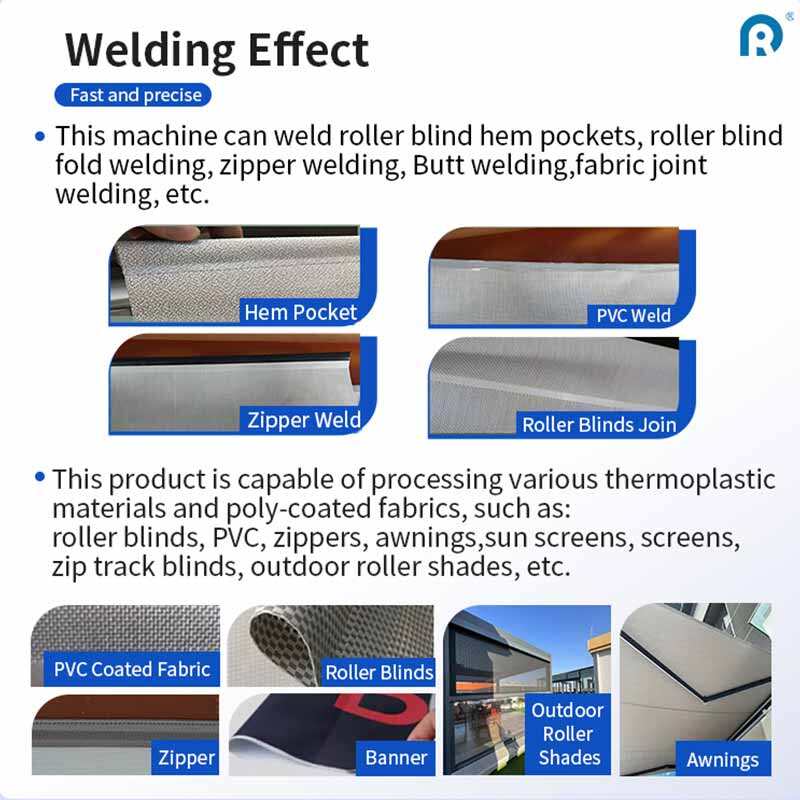

Curtain setting machines represent specialized tools used mainly in the textile manufacturing sector for making and putting together curtains effic...

View More