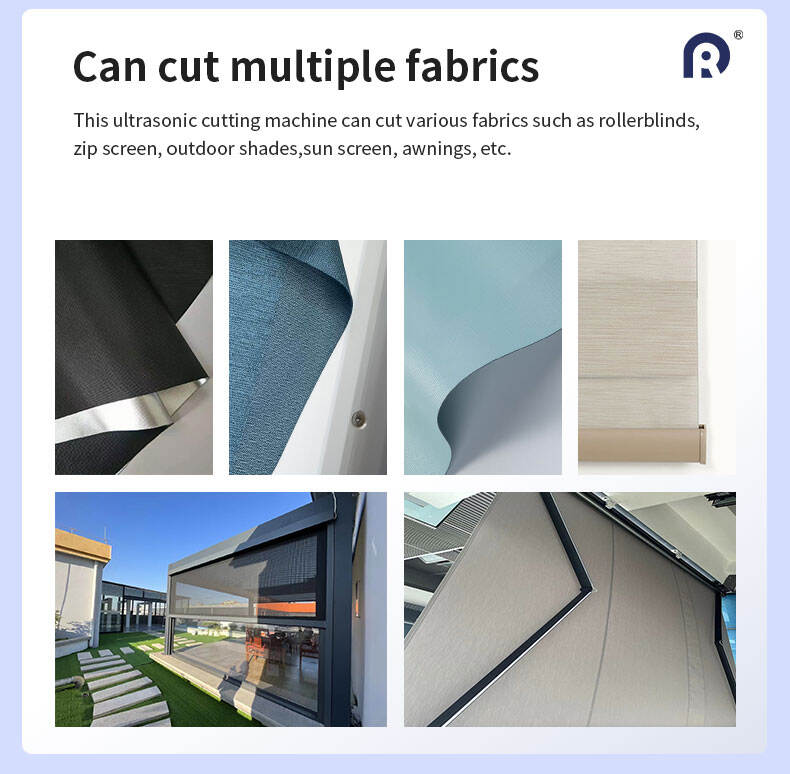

RIDONG CNC ultrasonic cutting tables utilize ultrasonic cutting to cut rectangular fabrics such as awnings, roller blinds, and outdoor sunshades. This fully automatic ultrasonic cutting table represents a revolutionary advancement in fabric processing technology, perfectly combining precision engineering with intelligent automation.

Description

Advanced Ultrasonic Cutting Solution: Precision & Efficiency in Fabric Processing

Key Features & Technical Specifications

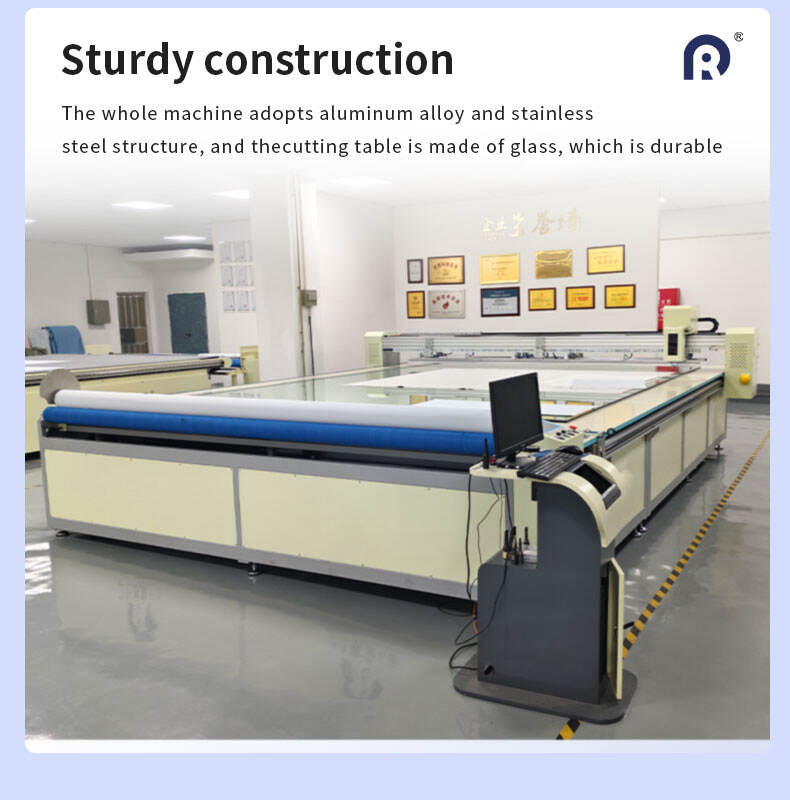

1. Cutting Capacity & Precision

- Maximum cutting dimensions: 320×400 cm (Customizable)

- Precision air cushion system for smooth glass sheet movement

- Stable steel frame construction with wear-resistant table top

- Universal tool supports (two per cutting axis) compatible with:

- Ultrasonic cutters (adjustable cutting angles)

2. Advanced Software & Automation

- Comprehensive PC software with:

- Fabric data database

- Tool selection optimization

- Cutting speed adjustment

- Offset value customization

- Graphical user interface with touch-screen operation

- Fabric usage optimization system (nesting and remnant storage)

- Blind and panel size calculation capabilities

3. Smart Integration & Connectivity

- Multiple interface options:

- Transmission interface

- Network interface

- USB port

- Offline operation capability

- Software format support (AI/DXF/PLT)

- Order entry via:

- Barcode scanning

- LAN connection

- Database system integration

Safety & Protection

- Comprehensive safety features:

- Induction anti-collision device

- Emergency stop button system

- Safety interlocks and guards

Optional Advanced Features

1. Automatic Material Handling

- Optional automatic winding and fabric pulling system

- Automatic loading and roll changing capability

- Fabric roll storage system integration

2. Roll Storage Solutions

- Fully automatic roll storage system available

- Capacity up to 800 rolls

- Optimized for high-volume production

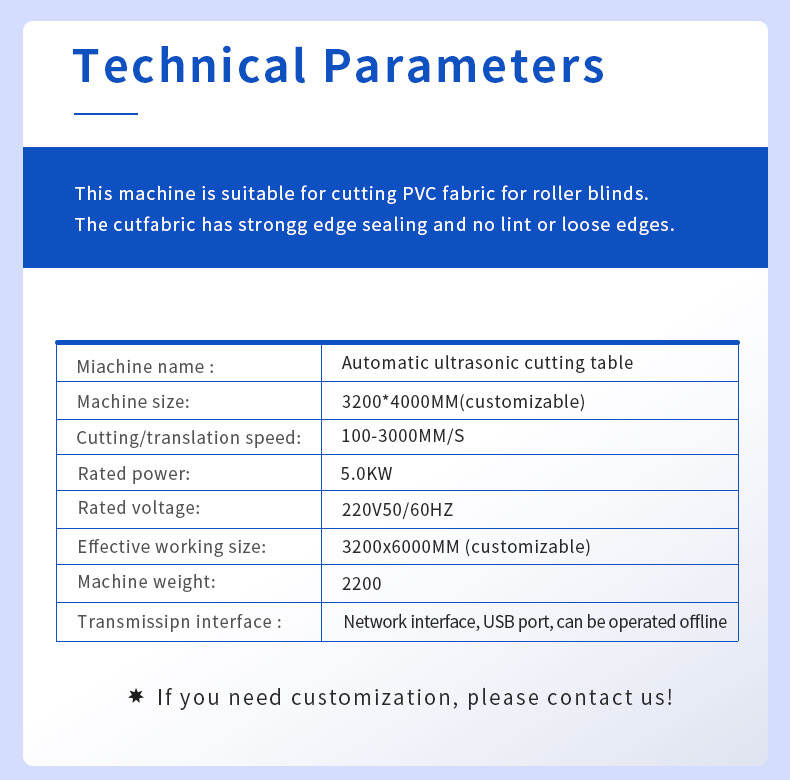

Parameter

| Machine model | RD-CQT3240 |

| Rated voltage | 220/110VAC50/60Hz |

| Air pressure | 3-6KG/cm2 |

| Rated power | 5KW |