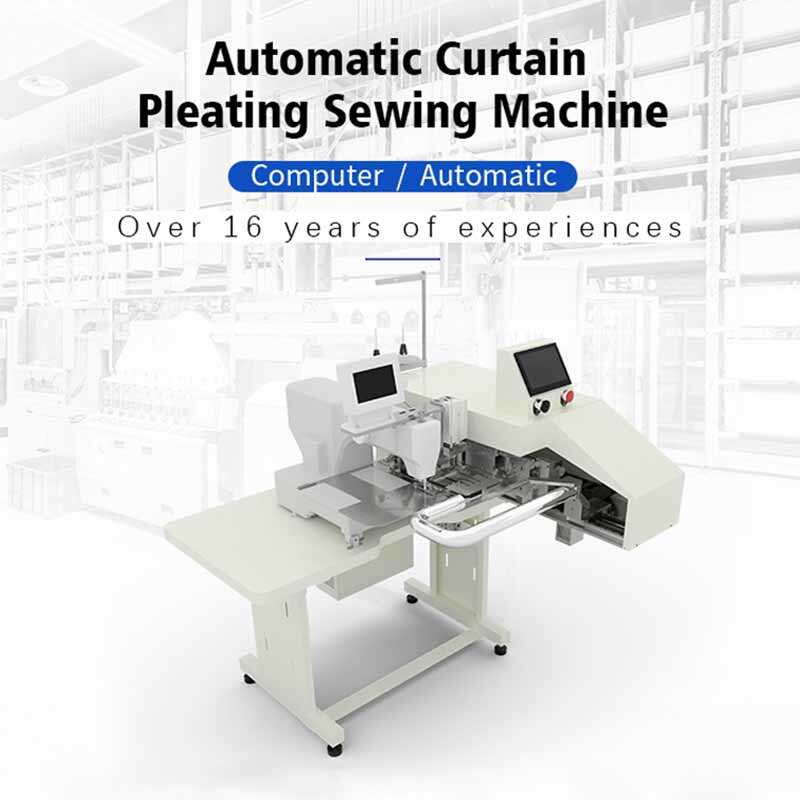

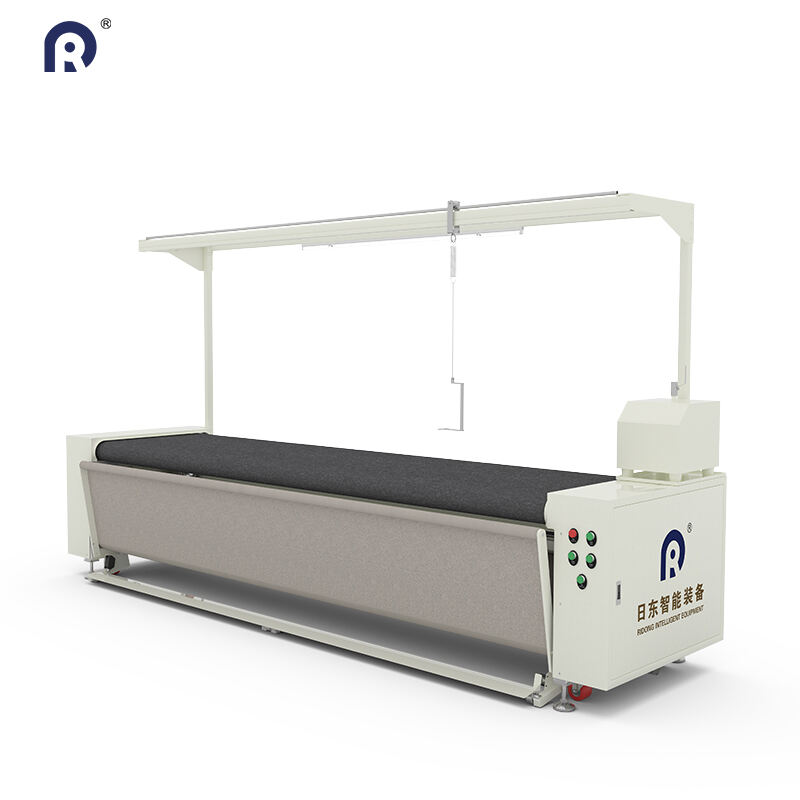

A complete curtain production line refers to an automated system of sophisticated machineries that includes every step of the manufacturing process, starting from rolling the fabric on a spool down to the packaging of the finished product. A fully integrated system includes conveyor fed cutting machines, robotic sewing arms, automated pleating systems, and quality inspection modules as their own distinct units. The system is set up to maximize productivity, which means real-time data tracking is implemented to optimize processes and reduce material waste. It is ideal for large factories, as with minimal labor the system functions automonously around the clock, making it possible to manufacture standard or customized curtains for hospitality, retail, and industrial uses.