This machine is used for edge cover stitching on curtain side sewing and hem, can also sew curtain head. Sewing head imported from Japan with good performance, quality stable. Desk uses conveyor, convey fabrics automatically speed synchronization convey.

Description

Advanced Curtain Sewing Solution: Precision & Efficiency in Window Treatment Manufacturing

The Automatic Curtain Hemming Machine represents a revolutionary advancement in curtain manufacturing technology, combining precision engineering with intelligent automation. This state-of-the-art Curtain Sewing Machine is specifically designed to handle all aspects of curtain edge finishing with exceptional efficiency and quality.

Key Features & Technical Specifications

1. Versatile Sewing Capabilities

- Primary functions:

Edge cover stitching on curtain sides,Hemming operations,Adjustable covered edge size for various specifications,Capable of handling thick fabrics without issues

This machine is used for edge cover stitching on curtain side sewing and hem, can also sew curtain head.

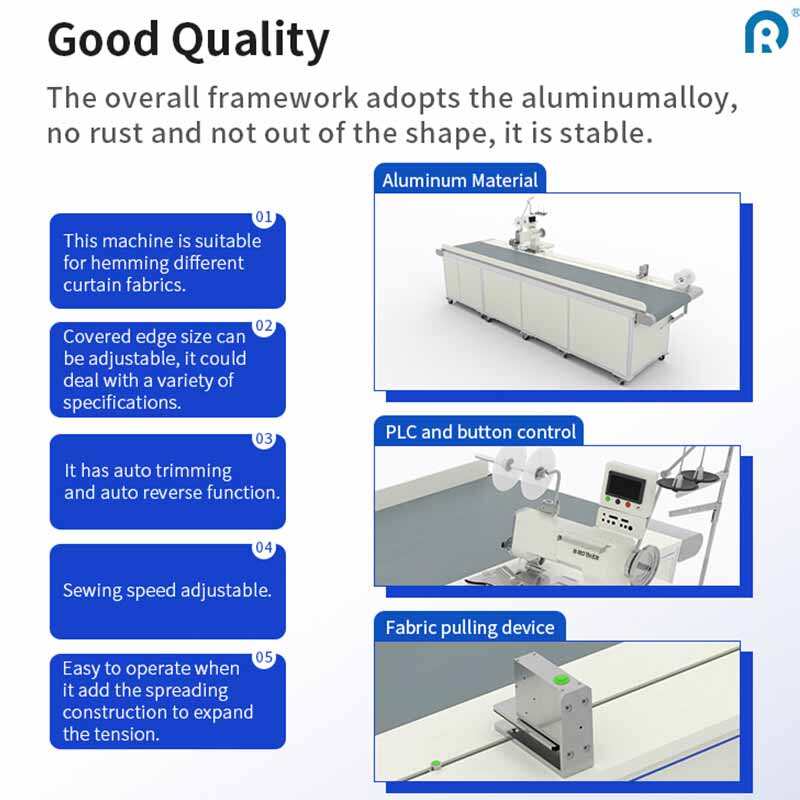

2. Premium Components & Performance

- High-quality Japanese brother sewing head

- Excellent performance stability

- Reliable operation

- Long service life

- Unique frame design:

- Prevents broken needles

- Eliminates dropped yarn issues

- Optimized for thick fabric processing

3. Advanced Automation System

- Conveyor-based worktable

- Automatic fabric conveyance system

- Speed synchronization between:

- Tug device

- Conveyor

- Sewing machine

- Smooth and beautiful final products

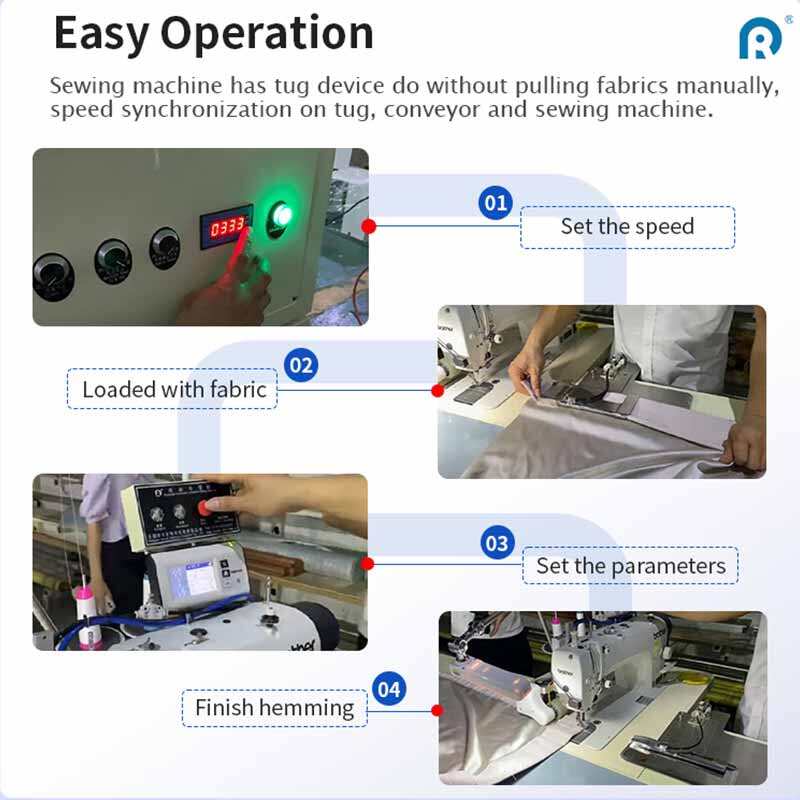

4. Operator-Friendly Features

- Spreading construction for tension adjustment

- Easy operation interface

- Manual fabric pulling eliminated through automation

- Adjustable settings for different fabric types

Applications & Benefits

The Curtain Making Machine is particularly well-suited for:

- Window treatment manufacturers

- Custom curtain fabrication shops

- Textile processing facilities specializing in window treatments

- Home decor product manufacturers

Key advantages include:

- Increased productivity through automated processes

- Consistent quality with synchronized operations

- Reduced labor costs through automation

- Versatility in handling various fabric types and thicknesses

- Easy maintenance and operation

- High-quality finished products

Production Capabilities

This Curtain Hemming Machine can handle:

Various curtain styles and sizes,Different fabric weights and thicknesses,Multiple edge finishing techniques,Custom specifications and requirements

Industry Applications

The Curtain Machine for Sales is ideal for:

Large-scale curtain manufacturers,Custom window treatment makers,Home decor product companies,Textile processing facilities

Why Choose This Curtain Machine?

1. Quality & Reliability

Premium Japanese components,Stable performance,Long-lasting durability

2. Efficiency & Productivity

Automated fabric handling,Synchronized operations,Reduced manual labor

3. Versatility & Flexibility

Adjustable edge sizes,Multiple sewing capabilities,Customizable settings

4. Operator Benefits

Easy to use interface,Reduced physical strain,Consistent results

Ideal for Curtain Machine Manufacturers

For manufacturers looking to enhance their production capabilities, this machine offers:

- Competitive edge in quality,Increased production capacity,Reduced operational costs,Versatile application possibilities

The Curtain Machine represents a significant advancement in window treatment manufacturing technology, offering unparalleled precision, efficiency, and flexibility. It's the perfect choice for manufacturers looking to enhance their production capabilities while maintaining the highest quality standards in curtain manufacturing operations.

Parameter

| Machine mode | RD-PFJ400 |

| Side wrapping size | 3.0/3.5/4.0cm |

| Bottom Hemming size | 8/10/12/15cm |

| Rated voltage | 220V |

| Rated power | 1.2KW |

| Air pressure | 3-6KG/cm2 |

| Machine Size | 3850*1500*1300mm |

| Machine weight | 330KG |