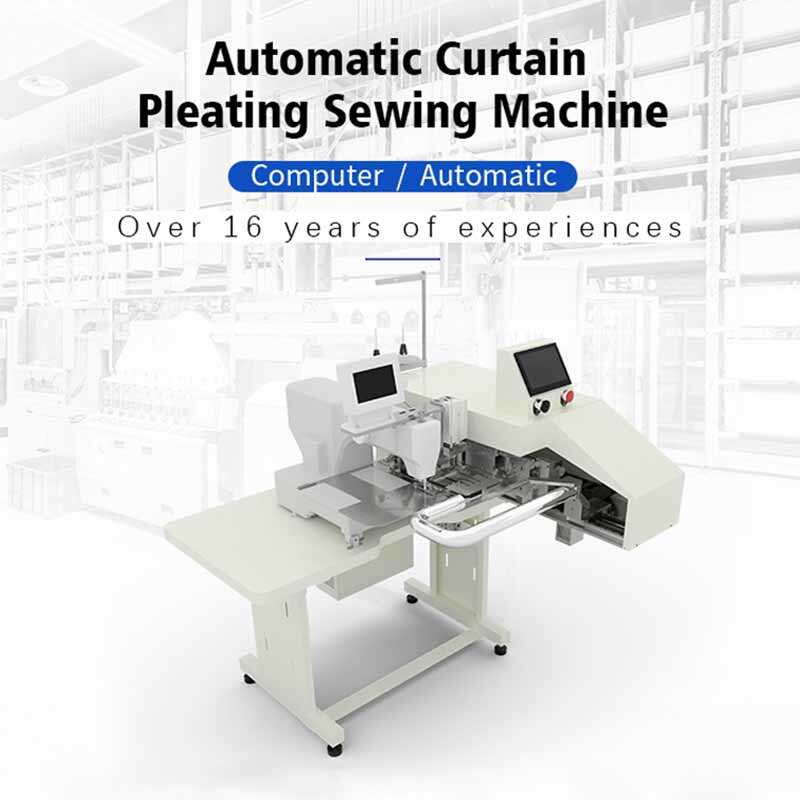

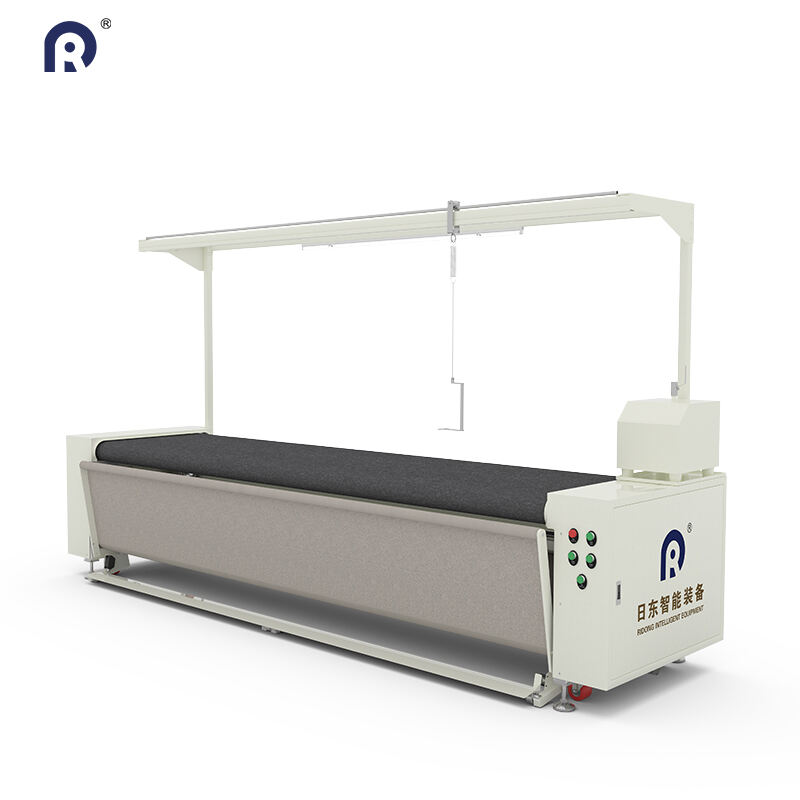

Curtain making equipment refers to all tools necessary for cutting, sewing, shaping, and finishing of a curtain. This equipment comprises of fabric cutting machines (rotary cutting machine, ultrasonic cutting machine), sewing machines (multi-needle sewing machine, straight-stitch sewing machine) and other devices like steam irons and hardware attachment tools. Ranging from simple handheld tools to off-the-shelf automated CNC machines, all of these machines are intended to increase precision and lessen labor without sacrificing quality across similarly styled and designed fabrics.