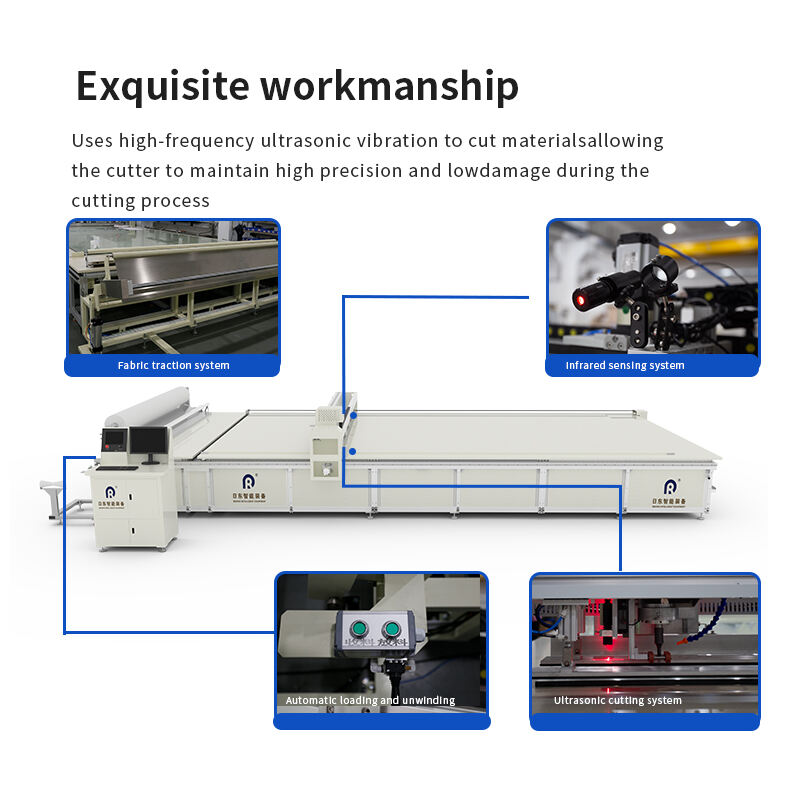

Ridong cutting table CNC controlled ultrasonic cutting table that uses a 360 degree rotating cutting axis to cut rectangular shapes such as panel blinds, roller blinds and exterior screens.The Fully Automatic Ultrasonic Cutting Table represents a revolutionary advancement in fabric processing technology, combining precision engineering with intelligent automation. This state-of-the-art Ultrasonic Cutting Table is specifically designed to handle large-scale fabric cutting operations with exceptional efficiency and accuracy.

Description

Advanced Ultrasonic Cutting Solution: Precision & Efficiency in Fabric Processing

Key Features & Technical Specifications

1. Cutting Capacity & Precision

- Maximum cutting dimensions: 320×600 cm

- Precision air cushion system for smooth glass sheet movement

- Stable steel frame construction with wear-resistant table top

- Universal tool supports (two per cutting axis) compatible with:

- Ultrasonic cutters (adjustable cutting angles)

- Pizza knife

- Crush knife

2. Advanced Software & Automation

- Comprehensive PC software with:

- Fabric data database

- Tool selection optimization

- Cutting speed adjustment

- Offset value customization

- Graphical user interface with touch-screen operation

- Fabric usage optimization system (nesting and remnant storage)

- Blind and panel size calculation capabilities

3. Smart Integration & Connectivity

- Multiple interface options:

- Transmission interface

- Network interface

- USB port

- Offline operation capability

- Software format support (AI/DXF/PLT)

- Order entry via:

- Barcode scanning

- LAN connection

- Database system integration

Safety & Protection

- Comprehensive safety features:

- Induction anti-collision device

- Emergency stop button system

- Safety interlocks and guards

Optional Advanced Features

1. Automatic Material Handling

- Optional automatic winding and fabric pulling system

- Automatic loading and roll changing capability

- Fabric roll storage system integration

2. Roll Storage Solutions

- Fully automatic roll storage system available

- Capacity up to 800 rolls

- Optimized for high-volume production

Applications & Benefits

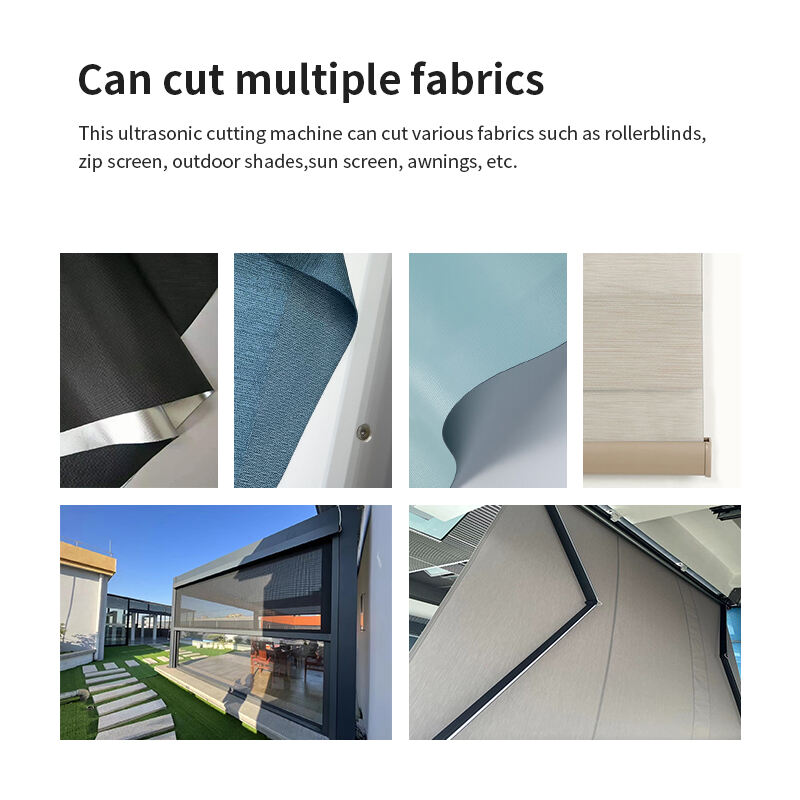

The Ultrasonic Fabric Cutting Machine is particularly well-suited for:

- Window blind manufacturers (especially roller blinds)

- Large-scale fabric processing facilities

- Custom blind fabrication shops

- Textile manufacturing plants

Key advantages include:

- Increased productivity through automated cutting processes

- Reduced material waste through intelligent nesting optimization

- Consistent quality with ultrasonic cutting technology

- Versatility in handling various fabric types and thicknesses

- Reduced labor costs through automation

- Easy integration with existing production systems

Customization & Scalability

- Machine dimensions customizable based on:

- Cutting dimensions

- Selected options

- Production requirements

- Flexible configuration options to match specific needs

- Scalable solutions for growing businesses

Industry Applications

This Ultrasonic Roller Blind Cutting Machine is ideal for:

- High-volume roller blind production facilities

- Custom roller blind manufacturers requiring precision cutting

- Textile processing plants with complex cutting requirements

- Industrial fabric cutting operations

The Ultrasonic Cutting Solution represents a significant advancement in fabric processing technology, offering unparalleled precision, efficiency, and flexibility. It's the perfect choice for manufacturers looking to enhance their production capabilities while maintaining the highest quality standards in fabric cutting operations.

Parameter

| Machine model | RD-CQT3260 |

| Effective working size | 3.2MX6M (can be customized) |

| Cutting speed/translation speed | 100-3000MM/S |

| Cutting thickness | 0.1-2MM |

| Power supply | 220V power 5.0KW |

| Cutting accuracy | ±0.1 |

| Equipment weight | 1800KG |

| Power supply | 220V |

| Rated power |

5.0KW |