Ripple Fold Sewing Machine: Cost-Effective Solutions for Interior Designers

Understanding Ripple Fold Sewing MachinesKey Features of Ripple Fold Technology

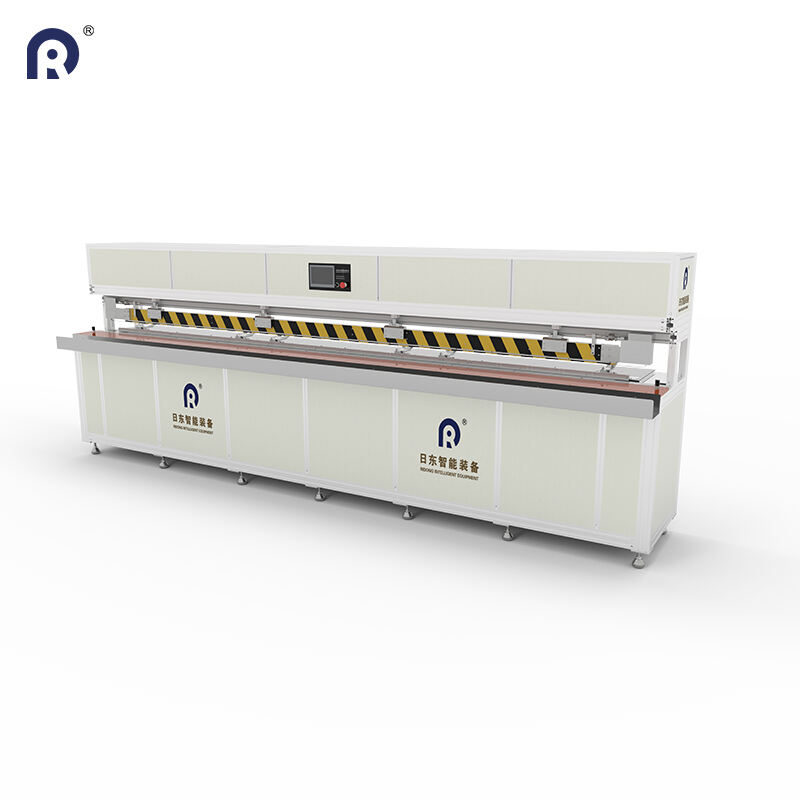

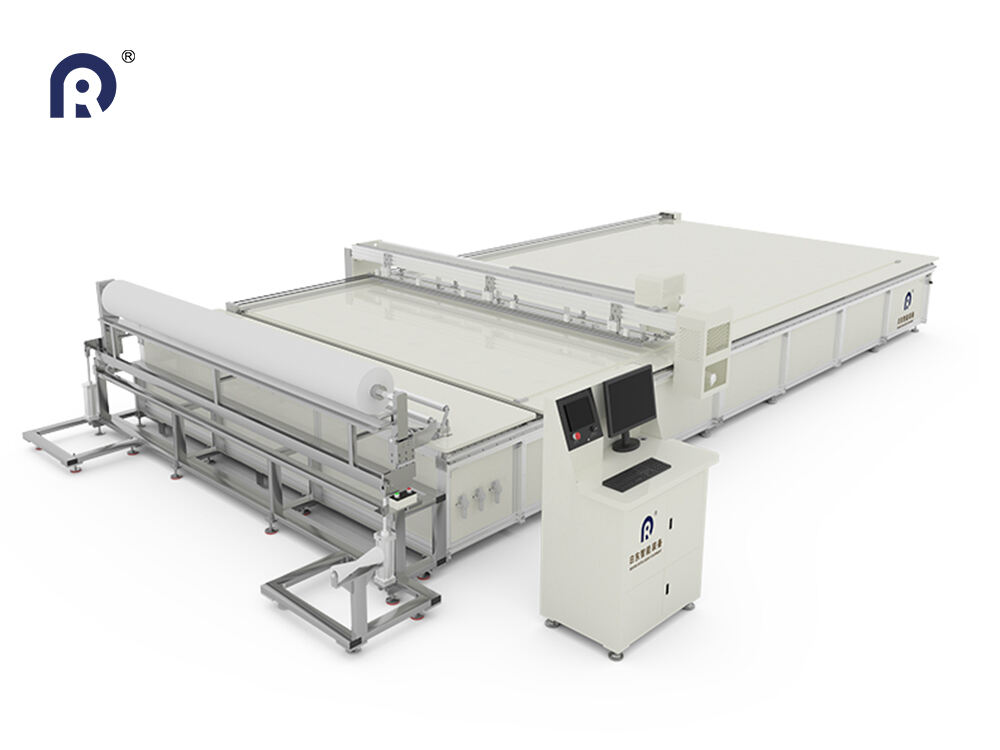

The ripple fold technique transforms how curtains look, thanks to special stitching methods that produce those beautiful wavy patterns everyone loves. What sets these mac...

View More