Why Advanced Curtain Equipment Matters for Modern Businesses

Meeting Evolving Consumer Demands

In the curtain industry, evolving consumer demands are driving a significant shift towards customization and unique designs. As modern buyers seek products that reflect personal tastes and preferences, businesses are compelled to offer personalized solutions. For example, a survey by Deloitte found that 36% of consumers express an interest in customized products and services, underscoring the shift toward personalized purchasing behaviors. Advanced curtain equipment allows companies to craft bespoke designs efficiently, meeting these demands. A case study highlighting a company that successfully employed such equipment showcases their rise in customer satisfaction and sales. By adopting advanced technology, businesses can stay ahead of market trends and cater to diverse consumer tastes effectively.

Reducing Production Costs Through Efficiency

Advanced automated curtain equipment plays a pivotal role in reducing labor costs and minimizing waste, leading to improved production efficiency. By incorporating machines like fabric cutting tables and welding mechanisms, companies can streamline their operations, reducing human error and material wastage. According to a report by McKinsey, businesses have seen up to a 12% reduction in production costs through automation. Lean Manufacturing principles can further enhance these efficiencies by optimizing processes to require fewer inputs while achieving top-quality outputs. Such strategic updates not only improve the bottom line but also position companies to invest in further innovations and expand their market presence.

Staying Competitive in a Digital Market

In today's digital landscape, staying competitive requires embracing technology and innovation, especially amidst the rise of e-commerce. Modern equipment is essential to meet the swift and often unpredictable online demand. Industry experts suggest that the companies leveraging cutting-edge tools like sewing machines for curtains see improved responsiveness and production scalability. Trends indicate a shift whereby businesses must adopt innovative practices to differentiate themselves and cater to tech-savvy customers. By pivoting toward digital solutions and incorporating advanced machinery, businesses can establish a competitive edge in the fast-paced online market landscape, ensuring long-term growth and relevance.

Key Technologies Revolutionizing Curtain Manufacturing

Precision Fabric Cutting Tables

Precision fabric cutting tables have become indispensable in the curtain manufacturing industry due to their ability to enhance accuracy and significantly reduce fabric waste. By leveraging advanced technologies such as laser cutting, these tables allow manufacturers to achieve precise cuts that were previously unattainable with traditional methods. One example of a notable improvement can be seen in companies that have experienced up to a 15% reduction in material waste after switching to these cutting tables. As technological advancements continue, features such as automated mat feeding and integration with design software are revolutionizing the way precision is handled in fabric cutting.

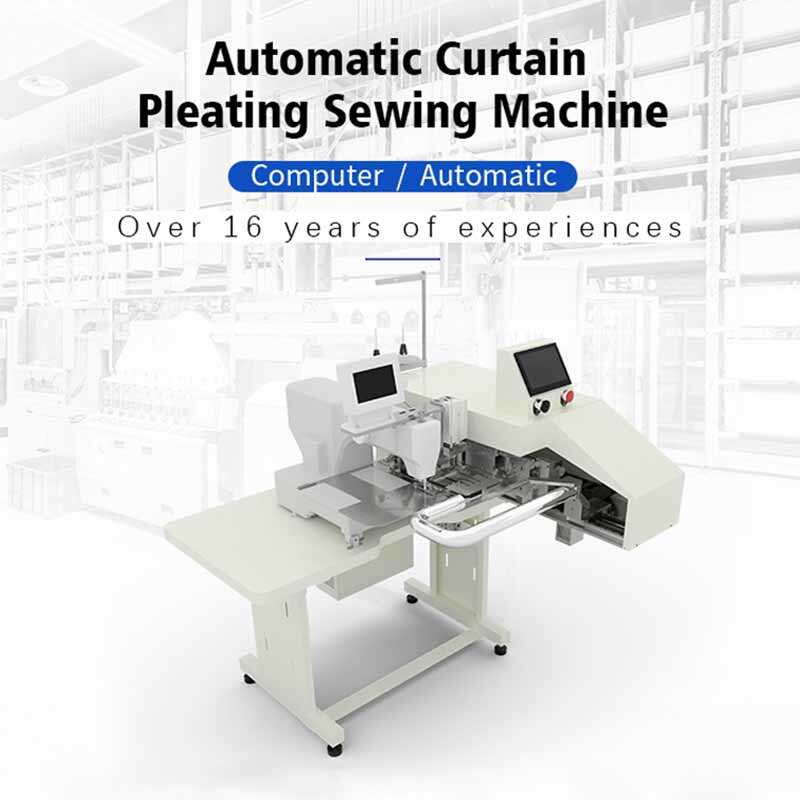

High-Speed Sewing Machines for Curtains

High-speed sewing machines designed specifically for curtains offer features that drastically improve production rates. This has been particularly evident when comparing older sewing models to modern advancements that boast faster speeds, increased stitching precision, and enhanced usability. For instance, new machines can handle thicker fabrics with ease, thereby reducing the time spent in sewing each curtain panel. Testimonials from curtain manufacturers who upgraded their equipment attest to a 25% increase in production rate, showcasing the machines' efficacy. These advancements mark a significant leap forward in efficiency and productivity within the curtain industry.

Automated Fabric Welding Systems

Automated fabric welding systems have transformed seam integrity and durability in curtain manufacturing. These systems provide a more robust seam compared to traditional sewing, making them ideal for creating waterproof or UV-resistant curtains. The reduction in labor time is another significant advantage, with some manufacturers reporting up to a 30% decrease in manual labor requirements since implementing these systems. By automating the welding process, producers can ensure a consistent product quality while simultaneously benefiting from reduced operational costs, positioning themselves advantageously in a competitive market.

Smart Curtain Making Machines

The integration of IoT in smart curtain making machines has introduced real-time monitoring capabilities, allowing operators to manage production with heightened efficiency. These systems are equipped with user-friendly interfaces that facilitate seamless interaction with the machines, reducing the likelihood of errors and enhancing overall workflow. Companies leveraging smart technology in curtain making report substantial productivity improvements, with some achieving a 40% increase in operational efficiency. Success stories abound of businesses revitalizing their production processes by adopting these innovative machines, thus illustrating the transformative potential of smart curtain manufacturing technologies.

Leveraging Automation and AI in Curtain Production

AI-Driven Pattern Optimization

AI technology is revolutionizing the curtain design process by optimizing patterns to reduce fabric waste significantly. Traditionally, designers faced challenges in efficiently utilizing fabric, leading to substantial waste, but AI-driven optimization tools analyze and refine designs to achieve maximum utilization. For instance, software like Adobe Sensei integrates AI to rethink fabric layouts and outputs designs that save time—a crucial advantage in the fast-paced manufacturing world. According to a study published in the Journal of Machine Learning, AI reduces design time by 20% and wastage by 15%, marking a substantial leap forward in efficiency.

IoT-Enabled Equipment Monitoring

The integration of IoT within curtain manufacturing presents a transformative opportunity for predictive maintenance, greatly reducing equipment downtime. IoT connected devices offer real-time monitoring, enabling facilities to anticipate maintenance needs before they impact production. Case studies, such as those highlighted by Harvard Business Review, indicate facilities that utilize IoT monitoring solutions see a 30% reduction in downtime and maintenance costs. As IoT technology evolves, experts predict its rising role in manufacturing, potentially shifting operational dynamics thoroughly.

Robotic Assembly Lines

Robotic assembly lines are at the forefront of enhancing production speed and consistency in curtain manufacturing. Robots, with their precise movements and unwavering efficiency, drastically elevate production rates. Data from the Manufacturing Institute highlights that implementing robotics in assembly lines can slash labor costs by 50% and increase consistency by 80%. Companies like IKEA have proven the potential of robotics by utilizing them for seamless curtain assembly, underscoring the profound benefits and advancements in utilizing robotic technology.

Sustainable Practices with Advanced Equipment

Energy-Efficient Fabric Welding Machines

Modern fabric welding machines are revolutionizing the way we approach manufacturing by significantly reducing energy consumption compared to older models. By harnessing innovative technologies, these machines contribute to lower utility bills and a smaller carbon footprint. For instance, some cutting-edge machines report up to a 30% decrease in energy usage, offering considerable cost savings for manufacturers. Moreover, adhering to sustainable practices allows companies to achieve eco-certifications, showcasing their commitment to environmental stewardship. This not only enhances a brand's reputation but also aligns with the increasing consumer demand for sustainable products.

Waste Reduction via Smart Cutting Systems

Smart cutting systems are pivotal in minimizing waste through their precise fabric usage capabilities. These systems effectively reduce fabric waste by using sophisticated algorithms, thus optimizing the cutting process and maximizing material utilization. Studies have shown that companies employing these advanced cutting systems have achieved up to a 20% reduction in fabric waste. Sustainability experts emphasize that such waste reduction is vital for both economic efficiency and environmental responsibility. By minimizing waste, manufacturers not only cut costs but also play a crucial role in fostering sustainable production processes.

Recyclable Material Compatibility

The ability of advanced equipment to work effectively with recyclable materials is a significant advantage in sustainable manufacturing. These machines are designed to handle a variety of sustainable materials, such as recycled polyester and organic cotton, which are gaining popularity in curtain production. Leading companies in the industry are increasingly incorporating these materials into their product lines, demonstrating a strong commitment to eco-friendly initiatives. By adopting recyclable practices, businesses can reduce waste, save resources, and contribute to a circular economy, ultimately leading to a more sustainable future in the curtain manufacturing industry.