The Role of Advanced Welding in Modern Sunshade Technology

Precision Welding for Durable Outdoor Fabrics

Precision welding plays a pivotal role in constructing durable outdoor sunshades that can withstand diverse weather conditions. By utilizing advanced welding techniques, manufacturers can enhance the strength and durability of seams, significantly reducing the likelihood of fraying or tearing over time. This technology is essential for creating sunshades that not only look aesthetically pleasing but also serve functional purposes. According to industry data, outdoor fabrics that are properly welded can have an extended lifespan, which offers a better return on investment for manufacturers. Incorporating precision welding in the production process ensures that the end product meets high standards of durability, which is crucial for customer satisfaction.

Integration with Fabric Cutting Tables for Efficiency

Integrating fabric cutting tables with welding processes is a game-changer for enhancing production efficiency. This integration minimizes handling and processing times, allowing manufacturers to streamline their workflows. Modern fabric cutting tables are equipped with programmable features, optimizing the layout to reduce fabric waste and improve overall material utilization. Studies have shown that automation in fabric processing, particularly with the integration of cutting tables, can boost production speeds by over 30%. This not only enhances efficiency but also ensures a higher quality of output, making it a vital aspect of modern sunshade manufacturing. By embracing such technologies, manufacturers can remain competitive in today's fast-paced market.

IoT-Enabled Welding Systems for Seamless Production

IoT-enabled welding systems are revolutionizing the production of roller blinds by offering real-time monitoring and troubleshooting capabilities. These systems enable us to monitor equipment performance continuously, allowing for immediate identification and correction of any issues that may arise during production. By collecting and analyzing data, these systems can predict potential machine failures before they happen, effectively reducing downtime and maintenance costs. According to recent research, integrating IoT into manufacturing processes can enhance efficiency by up to 25%. This significant improvement not only boosts production rates but also enhances product quality, ensuring a seamless production flow.

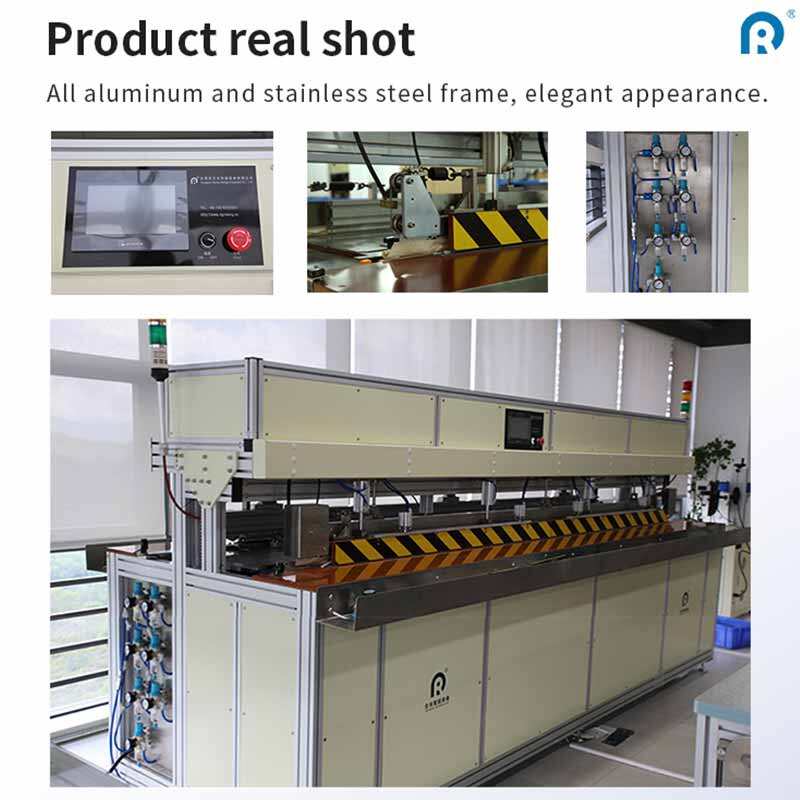

Automated Fabric Welding Machines for High-Volume Output

Maximizing high-volume output in sunshade production plants is efficiently achieved through automated fabric welding machines. These machines are specifically designed to streamline production lines, minimizing the need for manual intervention and labor, thus accelerating production processes. The versatility of these machines is noteworthy as they can handle an array of fabric types and thicknesses, catering to diverse sunshade designs. Statistics highlight that the adoption of automated systems can double the production capacity of sunshade manufacturing plants. This transition not only fulfills the growing market demand but also elevates the standard of curtain sewing machines, reflecting advancements in technology and production efficiency.

Sustainable Materials and Welding Innovations

Eco-Friendly Fabrics and Energy-Efficient Welding

Incorporating eco-friendly fabrics and energy-efficient welding techniques is crucial for modern manufacturing. Adopting sustainable materials not only caters to environmental trends but also meets increasing consumer demands for greener products. As more customers seek out eco-conscious items, offering roller blinds made from recycled or sustainable fibers aligns businesses with these preferences. Furthermore, energy-efficient welding processes significantly reduce the carbon footprint of the manufacturing workflow. Experts note that this shift can also enhance brand image, attracting a growing market segment of environmentally aware consumers eager to invest in sustainable products.

Reducing Waste with Precision Cutting and Welding

Precision cutting and welding techniques are pivotal in minimizing waste, reinforcing sustainability throughout the production process. By using advanced technology, manufacturers can significantly cut down raw material waste—by as much as 40%, according to recent data. Such efficient use of materials not only supports environmental goals but also boosts profitability. Companies focusing on waste reduction often find themselves financially rewarded, as cost savings from material efficiency directly translate to an improved bottom line. Additionally, precision techniques enable more accurate production processes, enhancing product quality and reducing errors during manufacturing.

Customization Demands in Outdoor Sunshade Production

Adapting Welding Machines for Curtain and Blind Designs

Customization plays a crucial role in meeting growing consumer demands for unique and personalized sunshade solutions. Welding machines must be adaptable, supporting varying design specifications for curtains and blinds to cater to diverse tastes. The flexibility of welding machines allows businesses to deliver a wide range of designs, enhancing customer satisfaction and ensuring the product's distinctiveness. According to industry reports, businesses offering customization can see a 20% increase in sales compared to those with standardized products. This trend highlights the importance of leveraging adaptable welding machines to remain competitive in the market and capture customer interest.

Software-Driven Patterns for Bespoke Sunshade Solutions

Advanced software solutions have revolutionized the process of creating bespoke sunshade patterns, tailored to individual customer preferences. This technology allows designers and manufacturers to experiment with various styles and designs without needing physical prototypes. By utilizing software-driven capabilities, sunshade providers can offer a personalized experience that resonates with customers, thereby enhancing their market position. Market analysis indicates that offering bespoke patterns can significantly differentiate companies in an increasingly competitive landscape. This presents an opportunity for businesses to stand out by providing exceptional and tailored products to discerning customers.