The Evolution of Curtain Hemming Machines: From Manual to Smart Automation

How Technological Advancements in Hemming Machines Are Reshaping Curtain Manufacturing

The latest curtain hemming machines now hit around 98% accuracy when it comes to stitching straight lines, way better than the roughly 24% we saw back in the day when people did everything by hand according to Textile Tech Journal last year. These new systems handle all sorts of fabrics without much trouble at all, whether it's delicate voile stuff or those thick blackout curtains nobody wants to see through. They pretty much stop those annoying puckers and broken threads that used to drive everyone crazy with older machines. Because of this improvement, factories can knock out big orders about 40% quicker these days while still keeping quality consistent enough to meet most industry standards. Some plants even report fewer returns because customers are happier with how evenly everything gets hemmed now.

From Manual to Fully Automatic: The Transformation of Curtain Hemming Machine Types

The evolution of curtain hemming technology spans five key generations, each marked by significant leaps in speed, accuracy, and automation:

| Generation | Operation Type | Max Speed | Error Rate |

|---|---|---|---|

| 1st (1970s) | Manual presser foot | 8m/hour | 12% |

| 3rd (2000s) | Semi-auto with PLC | 28m/hour | 5% |

| 5th (2020s) | AI-guided robotics | 85m/hour | 0.3% |

Today's laser-guided systems handle complex shapes like arched valances and 4-meter drapery panels interchangeably—tasks impossible for legacy equipment. This flexibility allows single-machine processing of custom designs without manual reconfiguration.

Balancing Cost and Efficiency: The Business Case for Upgrading Curtain Hemming Machines

Industrial curtain hemming machines require an initial investment of $25,000–$120,000, but deliver full ROI within 18–30 months through measurable gains:

- 67% reduction in labor costs for hemming operations

- 22% lower fabric waste due to precision edge alignment

- Threefold increase in order fulfillment speed for contract projects

According to the Smart Textile Alliance, facilities using AI-enabled systems report 19% higher profit margins than those operating decade-old machinery.

Industrial vs. Domestic Hemming Systems: Performance, Scalability, and ROI

Key Differences in Durability, Speed, and Stitch Quality Between Industrial and Domestic Setups

Industrial curtain hemming machines can run faster than 2 meters per minute thanks to their heavy duty steel frames built for non-stop operation. The home versions are much slower though, usually topping out around 0.8 meters per minute and made with lighter aluminum parts instead. According to research from the journal Reconfigurable Manufacturing Systems back in 2021, these industrial machines keep stitches consistent about 98% of the time after doing 10,000 cycles, whereas regular consumer models only hit around 78% consistency. There are several important differences when it comes to how well they perform overall.

- Durability: Industrial machines run 24/7 with annual maintenance; domestic units often fail after 500 hours

- Seam Quality: Pneumatic tension control prevents puckering on thick or delicate fabrics alike

- Throughput: Automated thread cutters and feed mechanisms triple output versus manual handling

When to Upgrade: Assessing Production Needs Before Switching to Industrial Curtain Hemming Machines

Workshops producing more than 150 linear meters daily should consider upgrading—industrial systems break even within 18 months for mid-sized operations. Below 50 meters, domestic machines remain cost-effective but demand 33% more labor per unit. Key indicators for upgrade include:

- Frequent seam failures on decorative curtain headings

- Over one-quarter of production time spent manually aligning fabric edges

- Increasing demand for mixed-material orders, such as linen-cotton blends

Are Domestic Machines Still Viable for Small-Batch Home Textile Hemming?

Makers who only make around 20 curtains a month will find that home hemming machines work just fine while costing about 62% less than professional models. The catch is those machines tend to have about 1.2mm variation in stitching which really shows up when working with delicate fabrics such as silk organza. But there's good news lately for crafters looking for better quality without breaking the bank. New developments in interchangeable presser feet mean hobbyists can actually create blind hems that look pretty much identical to what comes out of factories these days, all without needing to spend thousands on industrial grade machinery.

Smart Automation in Curtain Hemming: Precision, Consistency, and Future-Proofing

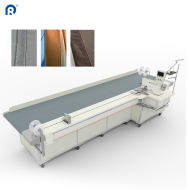

Real-time monitoring and error correction in advanced belt-style hemming machines (e.g., AT-212)

The belt style hemming machine model AT 212 comes equipped with built in sensors capable of spotting alignment issues or changes in tension almost twice as fast as any human worker could according to a recent report from Textile Automation in 2023. If the measurements go beyond 0.3 millimeters off track, the whole system will stop on its own and adjust the feeding part again. What does this mean for manufacturers? Less wasted fabric materials since these corrections happen right away. The machines can still produce consistent hems without problems even when running really fast, sometimes going over 25 meters every minute which is pretty impressive considering most traditional methods would struggle at those speeds.

Integration of hot melt adhesive technology for seamless, durable hems

The best systems out there today are moving away from regular stitching methods and instead using thermoplastic adhesives that get activated around 150 to 180 degrees Celsius. What happens next is pretty impressive - these bonds can reach strengths of about 12 Newtons per square centimeter, which is actually double what we see with normal sewn seams. Plus, they completely eliminate those annoying puckers that often appear on lightweight materials or fabrics that tend to stretch. According to tests done across different industries, these hot melt hems can last through well over 500 washing cycles. That makes them really suitable for things that get used a lot, such as blackout curtains in hotels or other hospitality settings where fabric needs to hold up against constant use without falling apart.

AI-driven adjustments and predictive maintenance: The next frontier in smart curtain hemming machines

Machine learning algorithms analyze fabric composition, thread tension, and adhesive viscosity to auto-adjust settings between batches, cutting setup time by up to 30%. Predictive maintenance alerts technicians to replace wear items—such as heating elements or drive belts—200–400 hours before potential failure, drastically reducing unplanned downtime.

Flexible Production Capabilities: Meeting Customization Demands with Modern Hemming Technology

Adapting Curtain Hemming Machines for Diverse Products: Curtains, Tablecloths, and Beyond

Today's hemming machines handle multiple products at once, making it easy to switch from blackout curtains to lightweight drapes or even thick tablecloths without swapping tools. The servo motors take care of adjusting stitches, tension settings, and feeding speed depending on what kind of fabric comes through the machine, whether it's something thin like 0.5mm mesh or heavier materials around 3mm thick. Shops that upgraded to these smart systems see changeover times drop by almost 80% and quality issues fall under 1%. This means manufacturers can quickly pivot production when seasons change, going from those breezy summer fabrics to festive holiday items like table runners right on schedule.

Supporting Small-Lot Customization Through Flexible Configurations in Commercial Hemming Systems

The modular setup of industrial systems allows workers to swap out different attachments depending on what orders come in. Think lace trimmers, bias tape applicators, maybe even hot melt adhesive dispensers when needed. Some companies are now using AI nesting software that cuts down waste materials by around 22%, according to Textile Tech Journal from last year. What does this mean? Well, it makes sense to produce batches as small as just five to ten items without breaking the bank. The real benefit comes through in making special order items like those custom café curtains customers love so much, or personalized bed skirts with names embroidered on them. And all this flexibility doesn't slow things down either. Machines can still handle between forty five and sixty hems every single hour, keeping up with regular production demands while meeting niche market requests too.

FAQ

What is the main advantage of using curtain hemming machines?

The main advantage of using curtain hemming machines is their accuracy and speed, allowing for 98% accuracy and reducing production time by about 40% as compared to manual hemming.

How do smart curtain hemming machines ensure quality?

Smart machines use real-time monitoring with sensors and AI-driven adjustments to maintain quality. They also incorporate hot melt adhesives for durable, seamless hems and offer predictive maintenance to prevent unplanned downtime.

When should a workshop upgrade to industrial hemming machines?

Workshops producing more than 150 linear meters daily should consider upgrading to industrial systems, which provide ROI within 18 months and reduce labor and waste costs significantly.

Are domestic hemming machines suitable for small production quantities?

Yes, domestic machines are suitable for small batches, such as 20 curtains per month, and are cost-effective despite having some stitching variations on delicate fabrics.

Table of Contents

- The Evolution of Curtain Hemming Machines: From Manual to Smart Automation

- Industrial vs. Domestic Hemming Systems: Performance, Scalability, and ROI

- Smart Automation in Curtain Hemming: Precision, Consistency, and Future-Proofing

- Flexible Production Capabilities: Meeting Customization Demands with Modern Hemming Technology

- FAQ