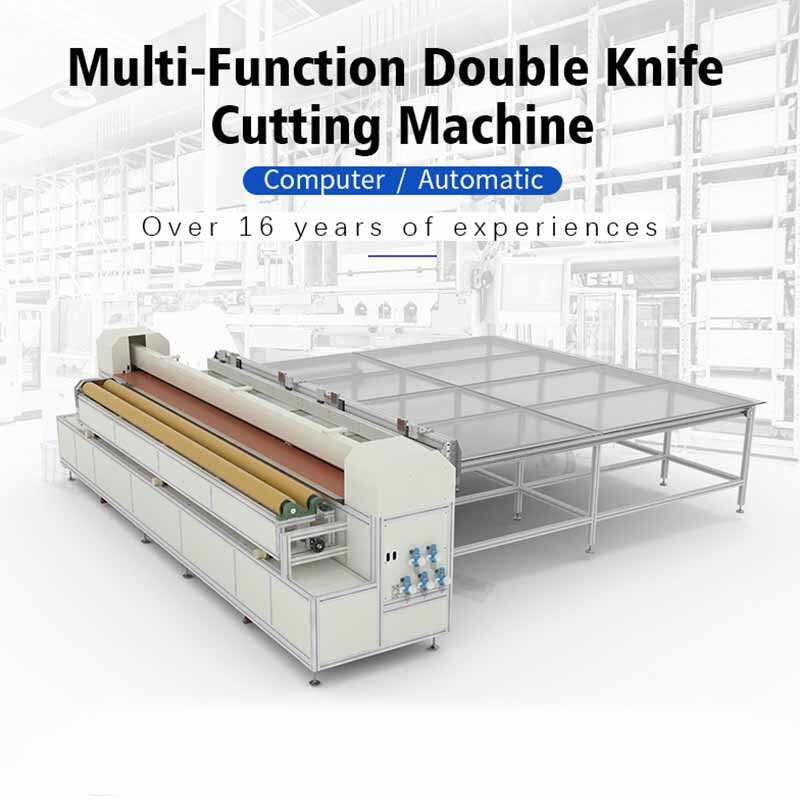

The Multi-Function Ultrasonic and Pressure Knife Cutting Machine represents a revolutionary advancement in fabric cutting solutions, combining the precision of ultrasonic cutting with the versatility of pressure knife technology in a single, efficient unit.

Description

Multi-Function Ultrasonic and Pressure Knife Cutting Machine: The Ultimate Solution for Curtain Fabric Processing

Introduction to Dual-Mode Cutting Technology

In the rapidly evolving roller blinds fabric processing industry, the integration of advanced cutting technologies has become essential for manufacturers seeking to maintain competitive edge while ensuring high-quality production. The Multi-Function Ultrasonic and Pressure Knife Cutting Machine represents a revolutionary advancement in fabric cutting solutions, combining the precision of ultrasonic cutting with the versatility of pressure knife technology in a single, efficient unit.

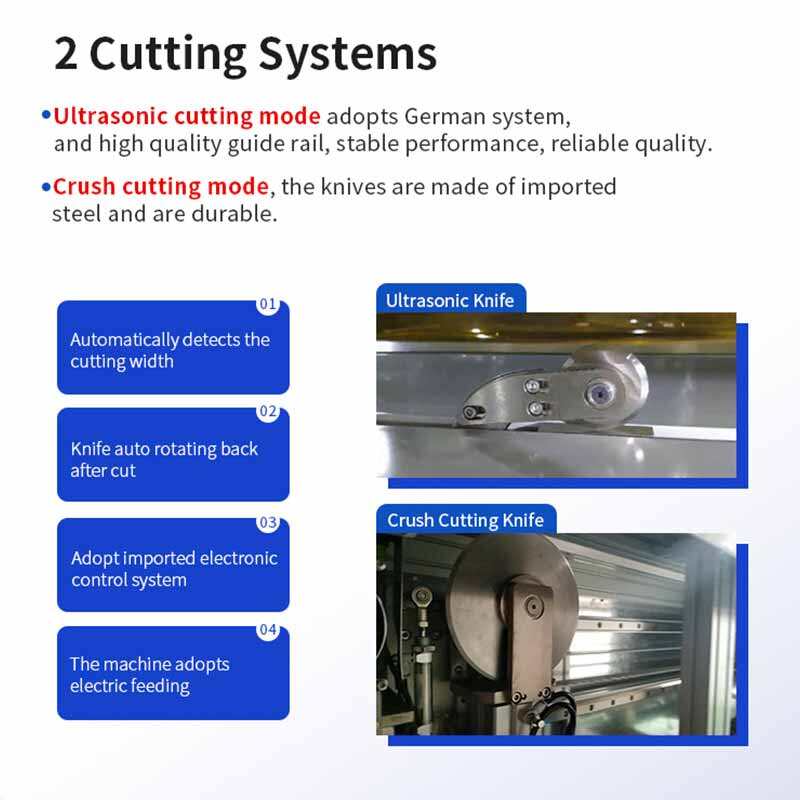

Unique Dual-Cutting System

The standout feature of this cutting machine is its innovative dual-cutting system, which allows operators to seamlessly switch between two distinct cutting modes:

1. Ultrasonic Cutting Mode (Ultrasonic cutting machine)

- Utilizes advanced ultrasonic technology for precise fabric cutting

- Ideal for most roller blinds fabrics including soft gauze curtains and Shangri-La curtains

- Features automatic width detection and knife return system

- Built with German ultrasonic system for superior performance and reliability

- The cut fabric has firm sealing edges and soft cutting edges, without shedding or losing edges.

2. Pressure Knife Cutting Mode (Pressure knife cutting machine)

- Specifically designed for challenging fabrics like double-layer zebra curtains

- Uses pressure-based cutting to achieve sealed edges without heat-related issues

- Made with imported high-quality steel blades for durability

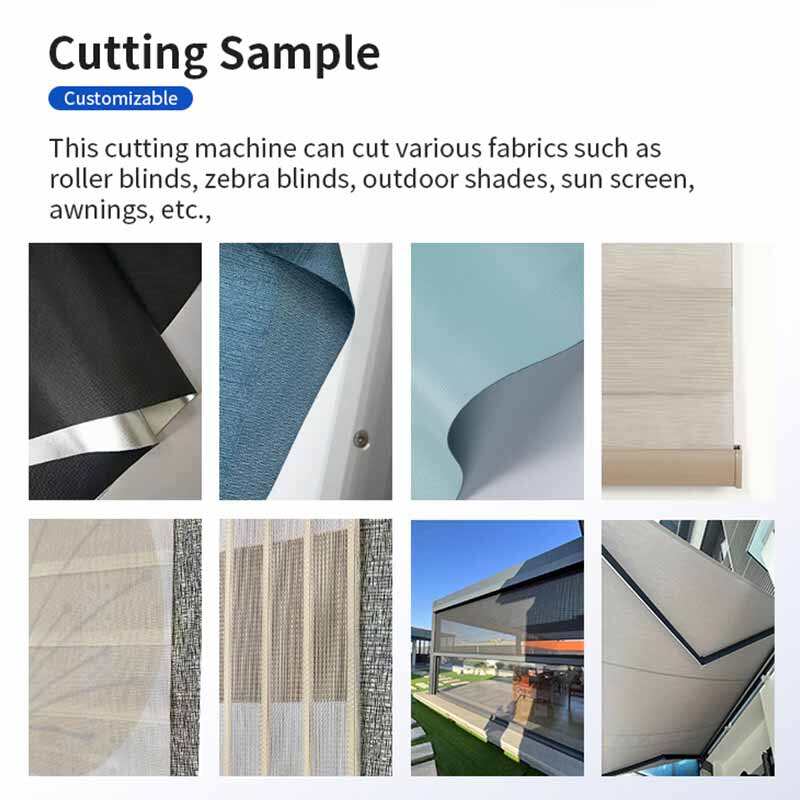

Material Compatibility and Versatility

This cutting machine is capable of processing an impressive range of curtain fabrics, covering over 95% of the market's blinds materials. The supported materials include:

- Roller blinds fabrics,Soft gauze curtains,Zebra blinds,Shangri-La curtains,And other specialized roller blinds fabrics

The ability to switch between ultrasonic and pressure knife modes ensures optimal cutting results for each specific fabric type, particularly addressing the common issue of fabric sticking that occurs when cutting double-layer zebra curtains with ultrasonic technology.

Advanced Features and Technical Specifications

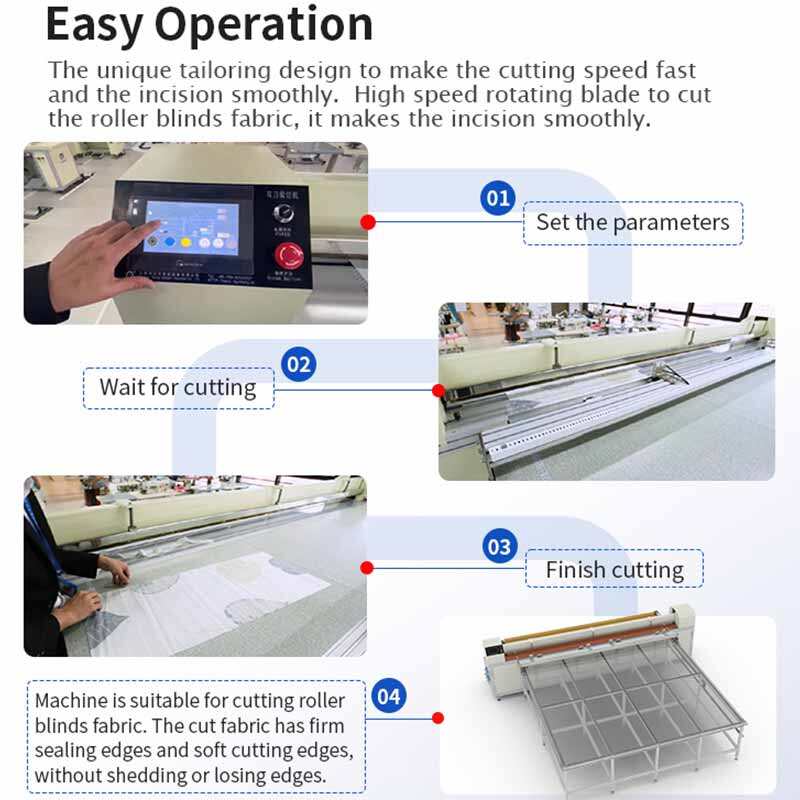

Cutting Performance

- Ultrasonic Fabric Cutting capabilities with precise edge sealing

- Ultrasonic Cutting Table design for stable operation

- Automatic width detection system for efficient production

- Intelligent knife return mechanism to enhance productivity

Material Handling

- Electric feeding system with adjustable length settings

- Remote control operation for increased efficiency

- Stable performance across various fabric thicknesses

Construction and Durability

- All-aluminum and stainless steel frame construction

- High-quality Taiwanese guide rails for smooth operation

- Japanese steel blades for long-lasting performance

- Beautiful and professional industrial appearance

Practical Applications and Benefits

The dual-mode cutting system offers several key advantages over traditional single-mode cutting machines:

1. Cost Efficiency

- Single machine handles multiple fabric types,Reduced need for specialized cutting equipment,Lower overall investment cost

2. Quality Assurance

- Consistent edge sealing without fabric fraying,Precise cutting accuracy for all fabric types,Professional finish on every cut

3. Operational Flexibility

- Quick switching between cutting modes,Remote control operation for convenience,Adjustable feeding length for various production needs

4. Production Efficiency

- Automatic width detection system,Intelligent knife return mechanism,Optimized workflow for high-volume production

Specialized Solutions for Zebra Blinds

One of the most significant advantages of this dual-mode cutting system is its ability to handle zebra blinds effectively. Traditional ultrasonic cutting can cause double-layer zebra bliinds to stick together due to heat generation. However, with the pressure knife mode, manufacturers can:

1. Achieve clean, sealed edges without heat damage

2. Maintain fabric integrity during cutting

3. Ensure consistent quality across all curtain types

4. Reduce production waste and rework

Technical Advantages

The machine's construction and components have been carefully selected to ensure optimal performance:

- German Ultrasonic System: Provides reliable power and stability

- Taiwanese Guide Rails: Ensures smooth and precise movement

- Japanese Steel Blades: Offers exceptional durability and cutting quality

- All-Metal Construction: Ensures long-lasting performance and stability

Conclusion

The Multi-Function Ultrasonic and Pressure Knife Cutting Machine represents a significant advancement in curtain fabric processing technology. By combining the precision of ultrasonic cutting with the versatility of pressure knife technology, this machine offers manufacturers a comprehensive solution that:

1. Handles 95%+ of roller blinds fabric types

2. Provides optimal cutting results for each fabric type

3. Reduces production costs and increases efficiency

4. Ensures consistent quality across all production runs

Whether processing delicate soft gauze curtains or challenging double-layer zebra blinds, this cutting machine delivers reliable performance and professional results, making it an essential investment for any blinds fabric manufacturer.

Parameter

| Machine model | RD-CQJ320D |

| Max cuting width | 2.5m/3.2/4.2m |

| Rated voltage | 220/110VAC50/60Hz |

| Rated power | 2.2KW |

| Air pressure | 3-6KG/CM2 |

| Machine Size | 4200*950*1100mm |

| Machine weight | 780kG |