Introduction

In today’s fast-evolving outdoor sunshade and architectural screening industry, the demand for precision, speed, and durability in fabric welding is higher than ever. Manufacturers, installers, and resellers know that poorly welded screens or sunshades mean product failures, unhappy customers, increased returns, and a damaged reputation. You need a reliable partner and the right equipment to guarantee beautifully finished products that last – and that’s where Dongguan Ridong Intelligent Equipment Co., Ltd. comes in.

Founded in 2007, Ridong specializes in the research, development, sales, and service of advanced roller blind machines, curtain sewing machines, and, most importantly, state-of-the-art fabric welding machines for the outdoor shading and screening industry.

With 18+ years of dedication, Ridong has gained trust across the domestic and global marketplace, delivering real solutions for everyday manufacturing pain points. In this article, we will focus on two high-demand machines: the zip screen welding machine and the external screen fabric welding machine, both engineered to solve specific production challenges and deliver lasting value.

---

What Is a Zip Screen Welding Machine?

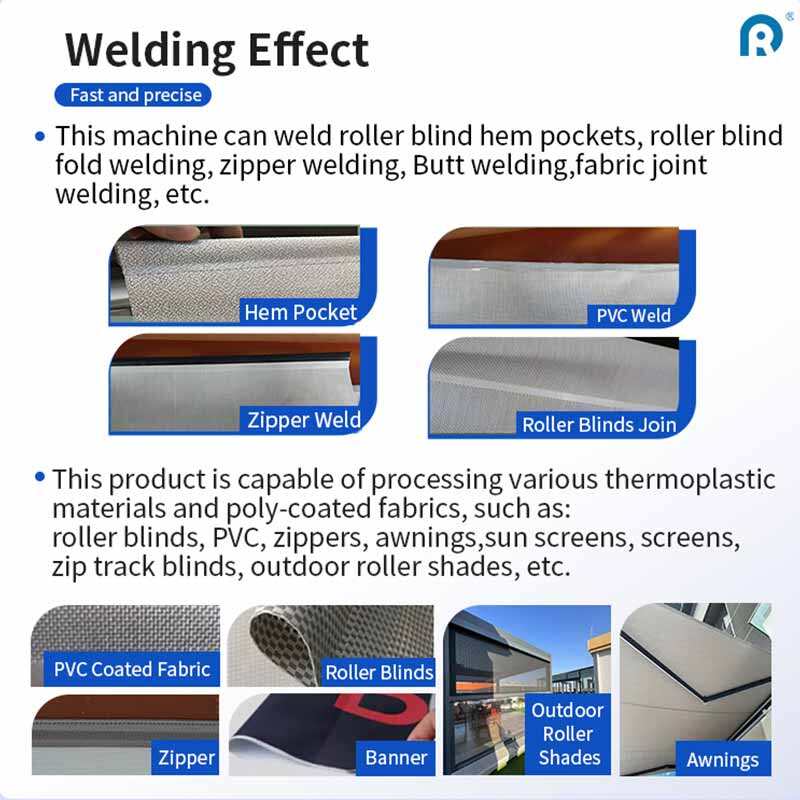

A zip screen welding machine is a specialized piece of equipment designed to weld and join zip tracks to fabric, creating strong, seamless, windproof blinds and screens. This type of machine is critical for manufacturers producing roller blinds, outdoor zip track shades, motorized zip screens, pergola screens, and other weatherproof or insect-proof solutions.

Ridong’s zip screen welding machine combines innovative technology with user-friendly controls. It’s built to streamline production, minimize manual errors, and deliver consistently reliable welds for both standard and custom zip screen projects.

Key Features of Ridong Zip Screen Welding Machines

- Precise Welding: Ensures accurate and clean seams, avoiding wrinkles, unevenness, and weak spots.

- Versatile Materials: Supports PVC, polyester, acrylic, mesh, blackout fabrics, vinyl, and more.

- Seamless Zip Track Integration: Attaches zippers or keder along the fabric edge quickly and securely, essential for windproof outdoor screens.

- Temperature & Pressure Control: Fine-tune welding parameters for different fabric thicknesses and types, preventing fabric damage.

- Automated Operation: Programmable settings and touch screen interface allow easy production runs and repeatable quality.

- Energy-Efficient: Designed for low power consumption, helping manufacturers control costs.

- Safety Features: Equipped with sensors and failsafes to protect operators during use.

---

What Problems Does the Zip Screen Welding Machine Solve?

It’s no secret that outdoor shades and screens face tough demands—sun, wind, rain, dust, insects. The weakest link is often the seam. Traditional sewing or manual welding can result in inconsistent joints that split, leak, or degrade. Zip tracks can detach, leading to costly call-backs and replacements.

Common pain points solved by a Ridong zip screen welding machine:

- Inconsistent Weld Quality: Manual techniques or old machines produce variable results. Ridong offers uniform, repeatable strength in every weld.

- Slow Production: Hand-welding or sewing slows down output, especially at high volumes. Automation with Ridong massively increases capacity.

- Labor Dependency: Skilled welders are in short supply and expensive. Ridong’s machines are operator-friendly, so you don’t need years of experience to excel.

- Material Waste: Bad welds mean scrapped fabric and zippers. Ridong machines reduce rejection rates and keep material usage efficient.

- Customer Complaints/Returns: Superior welds mean fewer problems in the field, happier clients, and stronger brand reputation.

Imagine producing thousands of flawless zip screens each month – Ridong’s technology makes it possible.

---

How Does the Zip Screen Welding Machine Improve Your Products?

1. Stronger, Neater Seams

Ridong’s zip screen welding machine uses adjustable heat and pressure to fuse fabrics and zippers. This creates a tight, unobtrusive joint that is stronger than traditional sewing, with no thread to rot or split.

2. Improved Weatherproofing

Properly welded seams are more airtight and watertight, helping you deliver windproof blinds and rain-resistant sunshades. This means your screens last longer outdoors and perform better under tough weather conditions.

3. Customizable for Project Needs

With easy controls and programmable settings, you can switch materials, fabric widths, and welding patterns for different contracts, whether you’re servicing commercial, architectural, or residential projects.

4. Scalability

Whether you’re a small workshop or a large manufacturer, automation reduces manual error, boosts staff productivity, and makes it easier to scale up as your orders grow.

---

External Screen Fabric Welding Machine – Heavy-Duty Solution for Larger Projects

When your business is tackling large external architectural screens, commercial awnings, patio enclosures, or high-end sunshades, a basic fabric welding machine won’t cut it. The external screen fabric welding machine from Ridong is engineered for durability, flexibility, and heavy-duty operation.

What Can the External Screen Fabric Welding Machine Do?

- Welds Large Fabric Panels: Handles extra-wide screens and long roller blinds up to several meters in width.

- Joins Diverse Materials: Welds PVC, mesh, acrylic, blackout, canvas, and technical textiles used in high-performance external screens.

- Ideal for XXL Projects: Suitable for building facades, commercial outdoor spaces, retractable pergolas, and oversized shading systems.

- Edge & Hem Seals: Welds hems, pole or keder pockets, flat seams, or double-sided joins.

- Integrated Cutting Options: Some models combine welding with precision cutting for “ready-to-mount” screen panels.

Advanced Features

- Programmable Welding Patterns: Custom software lets you preset welding functions for different product types.

- Heavy-Duty Construction: Built to handle nonstop manufacturing environments, with minimal maintenance requirements.

- High-Speed & Consistent Output: Enables mass production without sacrificing quality.

- User-Safe Interface: Safety locks, emergency stops, and intuitive controls protect staff during long shifts.

---

Challenges Solved by the External Screen Fabric Welding Machine

1. Managing XXL Materials

Manual welding of large fabric panels is a logistical challenge. Ridong’s machine is physically designed for handling wide-format material, ensuring every seam is perfectly aligned and securely welded.

2. Reducing Labor & Time

Traditional methods are labor-intensive and slow, especially for commercial jobs with tight deadlines. Automation means fewer workers needed per shift, and faster project turnaround with high accuracy.

3. Minimizing Defects & Rejects

Large-scale jobs mean big losses if seams fail. Ridong’s external screen fabric welding machine delivers strong bonds that pass stringent outdoor durability tests, even on oversized or specialty fabrics.

4. Expanding Business Opportunities

With a robust fabric welding solution, you can bid on bigger contracts, industrial jobs, and more demanding architectural projects that smaller workshops simply can’t handle.

---

How Do Ridong Welding Machines Stand Out?

1. Reliability and Durability

Ridong’s fabric welding machines are engineered for years of continual operation. Using high-grade components and smart design, they require little downtime for maintenance, helping keep your production schedules on track.

2. Real Technical Support

When you buy a Ridong machine, you get more than hardware. Our team offers full after-sales support, technical troubleshooting, and rapid spare parts to protect your investment.

3. Made for Industry Needs

We built our machines by listening to feedback from real manufacturers. This means practical layouts, easy cleaning, fast adjustments, and software that keeps things simple, not complicated.

4. Cost Savings Over Time

Yes, you might find a cheaper machine elsewhere – but cheap often means trouble:

- Higher repair bills

- Lower weld quality

- More wasted fabric

- Lost business

Ridong’s equipment is a long-term investment for competitive manufacturers who count every dollar.

---

Applications: Who Needs Zip Screen & External Screen Fabric Welding Machines?

Window Coverings & Blinds Manufacturers

- Zip-guided roller blinds

- Motorized zip track blinds

- Blockout roller shades

- Windproof mesh blinds

- Interior screen solutions

Outdoor Sunshade Producers

- Outdoor zip screens

- Pergola or pavilion screens

- Commercial patio enclosures

- Electric drop screens

- Retractable wind barriers

Architectural & Industrial Fabrication

- Building envelope facades

- Energy-saving external screens

- Large format shading systems

- UV and rain protection covers

Custom Solutions Providers

- Event tent makers

- Privacy screens

- Pool and fence enclosures

- OEM fabricators

---

Key Benefits at a Glance

|

Feature |

Benefit for Your Business |

|

Uniform seam welding |

Consistent product quality, fewer complaints |

|

High productivity |

Faster delivery, more contracts won |

|

Reduction in labor |

Lower wage costs, less reliance on skilled welders |

|

Minimized material waste |

Higher profit margins, eco-friendly operations |

|

Robust after-sales support |

Peace of mind, minimized downtime |

---

Why Choose Ridong? – Trusted Since 2007

1. Proven Track Record:

Our reputation comes from more than just good machines – we have thousands of satisfied customers in China and overseas. Ridong is known for honest business practices and standing by our promises.

2. Comprehensive Product Range:

From zip screen welding machines and external screen fabric welding machines to roller blind machines and curtain sewing machines, Ridong is a complete resource for the modern sunshade and screen manufacturer.

3. Customer-First Philosophy:

We’re committed to understanding your challenges and providing real-world solutions—whether you need a single machine or an entire production line upgrade.

4. Value for Money:

We balance leading technology with affordability, ensuring small and mid-sized manufacturers can access world-class equipment without breaking the bank.

5. Ongoing Innovation:

Our engineers continually update our machines to meet new industry standards, fabric types, and production needs.

---

Real-World Results: How Ridong Machines Transform Manufacturing

Case 1: Roller Blind Producer in Australia

Before: Struggled to deliver weatherproof zip screens for coastal homes. Old machines produced seams that leaked and zip tapes that detached under stress.

After Ridong’s zip screen welding machine: Seam failures dropped by 90%. Customer complaints evaporated. The business expanded into new, wind-exposed markets.

Case 2: Commercial Shade Contractor in the Middle East

Before: Large hotel projects had constant delays due to slow manual welding and frequent edge breakdowns on XXL external screens.

After Ridong’s external screen fabric welding machine: Doubled output speed, reduced labor by 40%, and delivered on time for even the largest projects.

---

Frequently Asked Questions (Q&A)

Q1: Is the Ridong zip screen welding machine compatible with all types of zip track systems and fabrics?

A1: Yes, our machine supports almost all standard zip track and keder systems, and welds a wide variety of fabrics including PVC, mesh, polyester, and blackout textiles. If you use a specialty material, we can advise on machine settings for best results.

Q2: What kind of training is included with the purchase?

A2: We offer full training to ensure your team gets up to speed fast. This can be done via video, on-site, or through detailed manuals, so even operators without welding experience can learn quickly.

Q3: How does Ridong’s after-sales service work?

A3: Our technical support is always available. We supply spare parts, troubleshooting advice, and fast fix solutions to minimize any downtime—no matter your location.

Q4: I’m worried about high repair costs and machine reliability. How do you help prevent downtime?

A4: Our machines are designed with reliability in mind. We use robust components and simple maintenance routines. If a problem arises, parts and service are available quickly, and most issues can be resolved with a call or video support.

Q5: Is there a risk of seams failing in harsh outdoor conditions or after long-term use?

A5: Not with Ridong! Our welding technology ensures the strongest possible bond and is proven in demanding outdoor installations around the world.

Q6: How does your machine save me money compared to competing products?

A6: With our precise welding, you experience less material waste, lower labor costs, and fewer warranty returns. The machine’s energy efficiency and reliability also reduce your ongoing operating expenses.

Q7: What’s the return on investment (ROI) for a new welding machine?

A7: Most customers recoup their investment in 6-18 months, thanks to higher quality products, fewer rejects, and new business opportunities that were previously out of reach.

---

Conclusion

In the world of sunshades, blinds, and outdoor screens, the difference between success and struggle often comes down to seam quality, production speed, and reliability.

Ridong’s zip screen welding machine and external screen fabric welding machine are engineered not just for today but for the evolving demands of tomorrow’s market. Whether you manufacture boutique window shades or massive architectural screens, our equipment gives you a competitive edge with durability, efficiency, and easy operation.

If you’re ready to:

- End seam failures

- Cut down on labor and material losses

- Win more contracts with speed and quality

- Grow into new product lines and markets

Let Ridong’s proven solutions work for you.

Contact us today for a tailored advice session and discover how our equipment can help your business thrive!