Introduction

When manufacturing awnings, choosing the right equipment is crucial for durability, efficiency, and cost-effectiveness. The two primary methods for joining awning fabrics are sewing and welding. Depending on your material and production needs, you may require an awning sewing machine, an awning welding machine, or even an awning double needle sewing machine for heavy-duty stitching.

This guide explores the differences between these machines, their best uses, and how to select the right one for your awning business.

---

1. Awning Sewing Machines: Stitching Fabric for Durability

What is an Awning Sewing Machine?

An awning sewing machine is designed to stitch heavy-duty fabrics like vinyl, polyester, canvas, and acrylic. These machines are built to handle thick materials and provide strong, long-lasting seams.

Types of Awning Sewing Machines

- Single-Needle Industrial Sewing Machines – Suitable for basic awning stitching.

- Double-Needle Sewing Machines – Ideal for reinforced seams, commonly used in awning double needle sewing machines for parallel stitching.

- Walking Foot Sewing Machines – Prevents fabric slippage, ensuring even stitching on thick layers.

Best For:

- Traditional fabric awnings (canvas, acrylic, polyester)

- Businesses needing flexibility in fabric choices

- Reinforced stitching for high-stress areas

---

2. Awning Welding Machines: Heat-Sealing for Waterproofing

What is an Awning Welding Machine?

Instead of stitching, welding machines use heat or high-frequency technology to bond synthetic awning materials (like PVC or polyethylene) without needles or thread.

Types of Awning Welding Machines

- Hot Air Welding Machines – Uses heated air to melt and fuse seams.

- High-Frequency (HF) Welding Machines – Uses radio frequencies to create airtight, waterproof bonds.

- Ultrasonic Welding Machines – Best for lightweight awning materials.

Best For:

- Vinyl, PVC, and other thermoplastic awning fabrics

- Waterproof and weather-resistant seams

- High-volume production with minimal thread wear

---

3. Sewing vs. Welding: Which is Better for Awnings?

|

Feature |

Sewing Machine |

Welding Machine |

|

Material Compatibility |

Canvas, acrylic, polyester |

PVC, vinyl, polyethylene |

|

Seam Strength |

Strong, but may need reinforcement |

Airtight, waterproof bond |

|

Production Speed |

Moderate (depends on stitching complexity) |

Fast (no thread changes) |

|

Durability |

Stitching may wear over time |

Seam is fused, no thread to break |

|

Cost |

Lower initial investment |

Higher upfront cost |

When to Choose Sewing:

✔ Using traditional fabrics (canvas, acrylic)

✔ Need flexibility in stitching patterns

✔ Lower budget for equipment

When to Choose Welding:

✔ Working with synthetic materials (PVC, vinyl)

✔ Need 100% waterproof seams

✔ High production efficiency required

---

4. Recommended Machines for Different Awning Needs

Best Awning Sewing Machines:

- RD-ZGPJ800(Heavy-duty double-needle machine,Walking foot for thick fabrics,Portable but powerful for awnings)

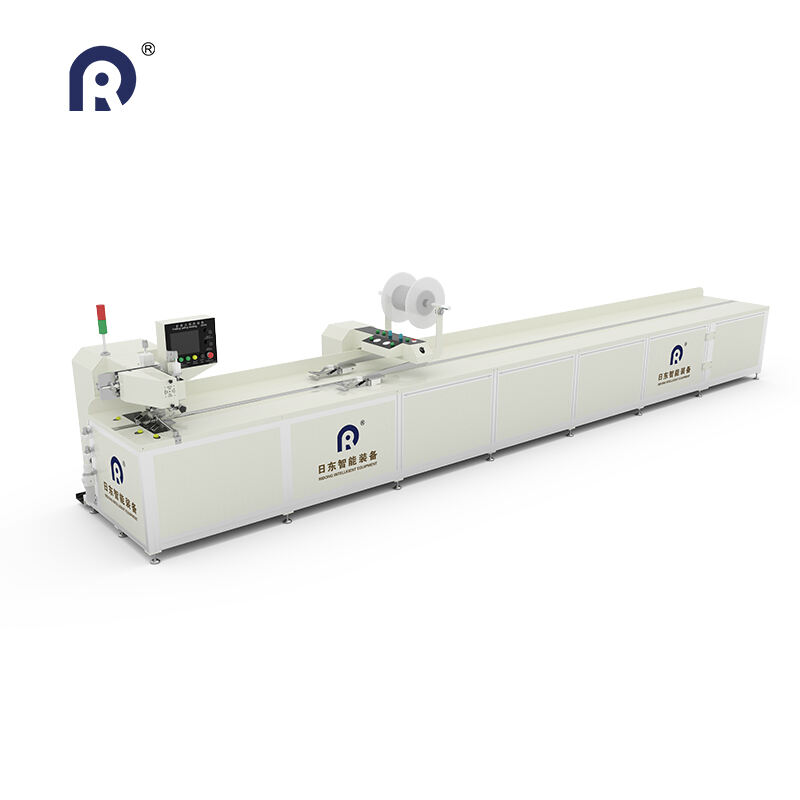

Best Awning Welding Machines:

- RD-ZPHJ1200(Hot air welder for PVC awnings,High-frequency welding,Professional-grade hot air tool)

---

5. Conclusion: Which Machine Should You Buy?

- For fabric awnings (canvas, polyester): An awning double needle sewing machine ensures reinforced seams.

- For synthetic awnings (PVC, vinyl): An awning welding machine provides waterproof, durable seams.

- For mixed materials: Some manufacturers use both—sewing for fabric parts and welding for waterproof sections.

By understanding your material and production needs, you can choose the best machine for high-quality awning manufacturing.

---

Final Thoughts

Whether you opt for an awning sewing machine or an awning welding machine, selecting the right equipment will impact your product’s durability and efficiency. Assess your fabric type, budget, and production volume to make the best decision.

Need help choosing? Contact us for expert advice on the best awning machines for your business!