שליטה על היסודות: מכונת ריתוך אוויר חם RD-ZGHJ1200 ליצירת בד PVC עילית לשימוש בחוץ

המראה של פתרונות מגורים וצל מסחריים בחוץ מתאפיינת בקשיחות, אסתטיקה, ובאתגר המתמיד של התמודדות עם תנאי מזג האוויר. בליבת ייצור הג'אזבים, הפראגולות, הסוככים והמבנים הגנים העצומים שעשויי PVC נמצא תהליך קריטי, קובע חיים או מוות: החיבור ההרמוני של לוחות הבד. שיטות מסורתיות כמו תפירה, סיכה או דבקים כימיים לא עומדות בדרישה, ויוצרות נקודות תורפות שפגיעות לקריעה, חדירת מים ופירוק על ידי קרני UV. החיפוש אחר הקשר המושלם והקבוע בייצור בד PVC מצא את תשובתו הסופית.

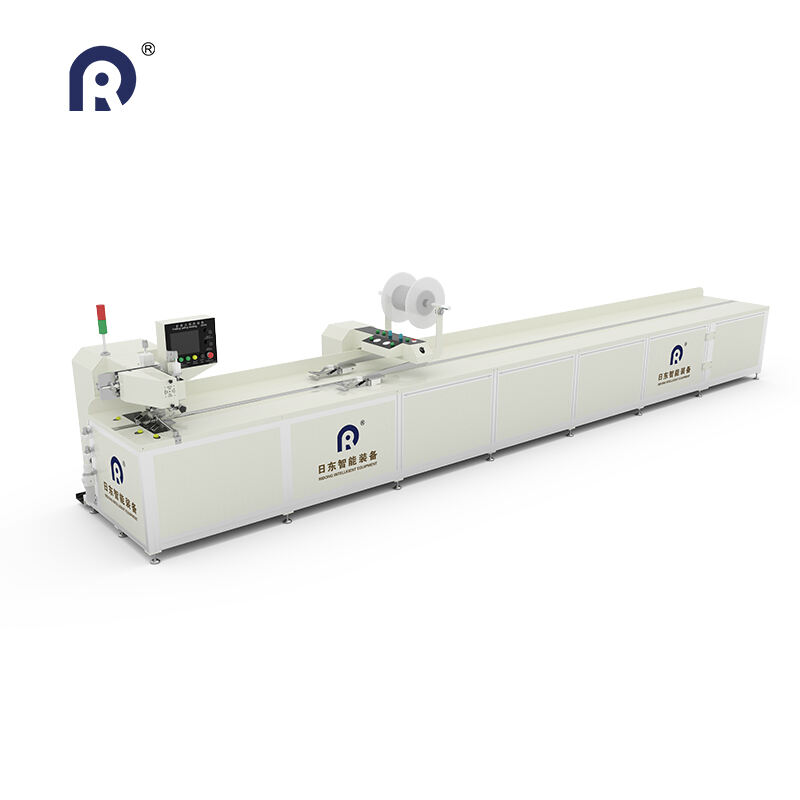

Dongguan Ridong Intelligent Equipment Co., Ltd., מובילה בתחום המכונות המתמחות מאז 2007, מציגה את מכונת הלחמת האוויר החם RD-ZGHJ1200 – פתרון תעשייתי ייעודי שנועד להפוך את ייצור מוצרי הצל של חומר PVC. המכונה הזו עולה על שיטות חיבור מסורתיות, ומציעה שלמות חיבור ללא תחרות, יעילות ייצור גבוהה ותוחלת חיים ארוכה של המוצר לייצרני קשתות PVC, מבני גינה, פרגולות ותלונות.

הדרישה הקריטית: למה חיבור בלחמת חומר PVC הוא הכרח מוחלט

חומר PVC לשימוש בחוץ, כולל בד פוליאסטר מצופה, למיםיני PVC ורשתות ויניל, מעוצבים לביצועים מיטביים. הם עמידים במים, בעדשים, בקרני UV ובתנודות טמפרטורה. עם זאת, כל חדירה לחומר – כמו חור מחט מתפירה – יוצרת נקודת תורפה וסיכון לכישלון.

החסרונות של שיטות חיבור מסורתיות:

תפירה: חורים של מחט מערערים את שלמותו של הבד בפני מים. החוט, לא משנה עד כמה הוא חזק, פגיע לדעיכה על ידי קרינת UV, מה שעלול להוביל לכישלון בתר seam. התר seam יוצר גם שפם שעשוי ללכוד אבק ומים.

דבקים וסרטים: עלולים להיות לא מסודרים, דורשים זמני עיבוד ארוכים, ומציעים חוזק דבק לא אחיד. הביצועים שלהם נוטים להידרדר עקב מחזורי טמפרטורה קיצוניים וחשיפה ממושכת לקרינת UV.

קשרים מכניים (עיגונים, ריבטים): מרוכזים על נקודות קטנות, וغالבfois הופכים לנקודות כשל עיקריות. הם גם פוגעים בשכבה ההגנתית של הבד.

יתרון ההלחמה: הלחמה, במיוחד הלחמה באוויר חם, מאחדת שתי חתיכות של בד מוכסה PVC ברמה מולקולרית. התהליך משתמש בחום מבוקר כדי למס את השכבות המוכסות PVC, שאותן דוחפים יחד כדי ליצור חיבור חד-גופי והומוגני. התוצאה היא תר seam ש:

חזק יותר מהבד הבסיסי.

100% עמיד בפני מים ולחים.

עמיד בפני קרינת UV בכל שטח התר seam.

שטוח ומלאכה אסתטית נקייה, ללא צלעות בולטות או חורים.

מהדורה ראשונה של RD-ZGHJ1200: מדריך לדיוק בהלחמה

ה-RD-ZGHJ1200 אינו מתקןلحם כללי; זהו מכשיר דיוק שתוכנן לצורך ייצור מסיבי ובאיכות גבוהה של מוצרים לשימוש בחוץ.

מפרט טכני עיקרי ופילוסופיית הנדסה:

יישום עיקרי: מתמחה בהצמדת בדיד PVC והלחמת סרטים חותמים לגזיבוס PVC, מבנים גנים PVC, פרגולות PVC ותריסים PVC.

טכנולוגיה להלחמה: מערכת לحام חום מתקדמת (תראמית). שיטה זו מספקת שליטה טובה בהרבה על טמפרטורה וזרימת האוויר בהשוואה למכשירי לחימה פשוטים יותר, כמו אלו בעלי אימפולס או תדר גבוה, מה שהופך אותה לרצויה במיוחד לעיבוד בדדים עם עוביים וเคล coatings משתנים המשמשים בחוץ.

אורך ריתוך מהפכני: תכונה בולטת היא היכולת לריתוך חד-פעמי ורציף באורך של עד 10 מטרים. יכולת זו מהפכנית לייצור של חתכי גג בטווח גדול למדשאות, פרגולות או טרסות מסחריות גדולות, ללא חיבורים ביניים שאינם אסתטיים וחלשים.

עקרון העיצוב: בנוי בהתאם לערכים המרכזיים של Ridong – "ניהול ישר, איכות אמינה, הלקוח קודם" – ה-RD-ZGHJ1200 מדגיש עמידות, אמינות תפעולית ועיצוב המורכב מהמשתמש, במטרה למקסם את תפוקת הפקס.

פירוק מערכות מפורט:

1. מערכת החימום והזרימה המדויקת:

ליבת ה-RD-ZGHJ1200 היא אלמנט החימום הנשלט דיגיטלית והמאוורר התורביני. בניגוד לריתוכים בסיסיים עם חום לא יציב, המערכת הזו מציעה:

בקרת טמפרטורה מסוג PID: שומרת על טמפרטורת האוויר הרצויה בסטייה של ±2° צלזיוס, מה שחיוני לריתוך עקבי של ציפוי ה-PVC מבלי לשרוף את רקמת הבד או להשאירו מחובר בצורה לא מספקת.

נפח זרימת אוויר ניתן להתאמה: מאפשר למשغلים לכוונן במדויק את חום הלחיצה עבור משקלים שונים של בד – מבדים קלי משקל של חיפויים עד PVC כבד, רב-שכבות לצלעות.

עיצוב נozzle אחיד: ה-nozzle ללחיצת הבד מעוצב לחלק את האוויר החם באופן אחיד לאורך כל רוחב הצלע, וכך מונע נקודות קרות שמובילות לחיבורים חלשים.

2. מנגנון הנעה והנחייה:

השגת ריתוך מושלם לאורך 10 מטרים מחייבת טיפול מושלם בחומרים.

גלגלי הנעה סינכרוניים: גלילים עליונים ותחתונים ממונעים מושכים בעדינות את שכבת הבד דרך אזור הלחיצה במהירות אחידה וניתנת להתאמה. זה מבטיח יישום אחיד של חום וכוח.

מערכת ניווט לייזר או מעקב שוליים: מערכת ניווט משולבת מקרינה קו מדויק על הבד, ומאפשרת למשתמש להציב את הלוחות בצורה מושלמת למסלולי ריתוך ישרים או מורכבים. דגמים מתקדמים יכולים לכלול חיישני מעקב אוטומטיים אחרי השפה.

בקרת לחץ מתכווננת: הלחץ שמפעילה רוללת הלحام ורוללת הקירור העוקבת הוא מתכוונן. לחץ נכון חיוני כדי לדחוף את שכבות ה-PVC המומסות לערבב זו בזו וליצור חיבור חזק וחופשי מفقקים בעת הקירור.

3. אינטגרציה של מזון לשדרית חיבורים (חוט לحام):

לשימושים הדורשים תפרים מחוזקים, ניתן לצייד את דגם RD-ZGHJ1200 במזון אוטומטי לחוט או סרט לحام PVC.

החוט הזה מוזן ישירות לתוך החיבור החם, נמס ונצרך ויוצר חיבור משולש עבה וחזק במיוחד. זה חיוני לתפרים מבניים בسقوפי ג׳יזבו או בהיקף של ארוגות ממותקות.

יישומים טרנספורמטיביים: אזורי התמחות של ה-RD-ZGHJ1200

היכולות של המכונה עונות ישירות על הצרכים הייצוריים של מספר תחומי מוצר מרכזיים בתחום החוץ:

1. ייצור ג׳יזבו ופראגולה מ-PVC:

האתגר: ליצור לוחות גג גדולים וחסינים ממים שיכולים לעמוד בגשם, ברוח ובשלג ללא דליפות.

פתרון RD-ZGHJ1200: מאפשר יצירת מקטעי גג חסרי הרכבה באורך עד 10 מטרים, ללא צורך בפריטים מחוברים מרובים. החיבור המוגבב הוא שטוח וחזק, מונע הצטברות מים ופיזור מתח באופן אחיד לאורך כל המבנה.

2. טרסות PVC מסחריות ודיוריות:

אתגר: ייצור של כיסויי טרסה עמידים ומושכים מבחינה אסתטית, הנשארים מתוחים וחסרי דליפה לאורך שנים.

פתרון RD-ZGHJ1200: מאפשר חיבור של בדידים ברוחב גדול לגודל מותאם עם חיבורים נראים-למחצה ו chống מים. אידיאלי לגיבוב סרטים לקיפול, יצירת קיפולים מחוזקים למשענות טרסה, והוספת כיסויי קצה או עיניים על בסיס מוצק ומחובר.

3. בדידים גינה PVC, לוחות מבנים מתנפחים וכיסויים מגינים:

אתגר: הבטחת חסימת מים מוחלטת ועמידות מתיחה גבוהה למוצרים כמו כיסויי בריכה גדולים, בדידים למשאיות או לוחות אוהלים לאירועים.

הפתרון RD-ZGHJ1200: מספק חיבורים חסיני אויר וחסיני מים, המסוגלים להחזיק לחץ אויר (במוצרי ניפוח) או לעמוד בטענונים כבדים של מים. עמידות החיבור בפני ירקות ועִקּוּש היא גבוהה בהרבה מאלו המחוברים באמצעות תפר.

ההחזר הניכר על ההשקעה (ROI)

השקעה ב-RD-ZGHJ1200 תתרjom להבטים תחרותיים מדידים ויתרונות פיננסיים:

1. איכות מוצר ועומס ייחודיים:

הבחנה שוק: המוצרים כוללים בנייה "בלי seems" או "מאוחדים", טיעון שיווקי חזק המצדיק תמחור פרימיום.

צמצום דרמטי בדרגות הכשל: הסרת דליפות או קרעים הקשורים ל-seam מובילה למספר מוגבל יותר של טענות אחריות, תיקונים והתלוננות לקוחות, ובכך מגינה על מוניטין המותג.

2. שיפור דרמטי ביעילות הייצור:

מהירות: איחוד באוויר חם, במיוחד עם קיבולת ה-10 מטר, מהיר באופן משמעותי מתפירה של בד PVC עבה. הפתרון מאחד את הגזירה והאטימה בעבר אחד.

אופטימיזציה של עבודה: הפעלה חצי אוטומטית דורשת פחות כישורים מאשר תפירה תעשייתית ומצמצמת עייפות עובד המשויכת לטיפול בבדים כבדים.

מוכן 24/7: בנוי לסיבולת תעשייתית, המכונה תומכת בפעולת משמרות רציפה, ומקסמת את תפוקת המפעל.

3. חיסכון בעלויות חומר ותהליך:

מבטל צורכי בעבודה: אין צורך בחוט עמיד ב-UV, דבקים או סרט איטום יקרים.

מפחית עבודה חוזרת: עקביות הלחמה האוטומטית ממזערת שגיאות אנוש ושחיתת חומר עקב התפרים לקויים.

צריכת אנרגיה נמוכה יותר: בהשוואה לחלק מהמחלטים בתדר גבוה, מערכת האוויר החם יכולה להיות יעילה יותר אנרגטית עבור בדים בני טריז עד בינוני.

מעבר למכונה: השותפות עם Ridong

בחירת ה-RD-ZGHJ1200 פירושה שותפות עם חברה שמערכת הערכים שלה משובצת במוצרים שלה. המסע של 18 השנים של Ridong, שנוקטת בעמדה של "איכות מעולה ומחירים סבירים", מבטיחה שהמכונה הזו היא לא רק טכנית מתוחכמת אלא גם אמינה ונגישה.

תמיכה מקיפה: מניתוח יישום ראשוני ותצורת מכונה, דרך התקנה באתר ועד אימון מקיף של המפעילים.

מומחיות טכנית: גישה למהנדסים שמבינים את ההבדלים הדקים בלחימת בד PVC ויוכלו לספק ייעוץ מתמשך לאופטימיזציה של התהליך.

אבטחת איכות: כל מכונה היא עדות ל"איכות אמינה", בניהה מרכיבים עמידים לתקופת שירות ארוכה בסביבות דרמטיות.

מסקנה: שינוי הסטנדרט לייצור חוץ

מכונת הלחמת האוויר החם RD-ZGHJ1200 היא יותר מפריט ציוד מפעל; זו השקעה אסטרטגית בעתיד של עסק ייצור. בתעשייה שבה אורך חיי המוצר וرיעות הלקוחות קשורים ישירות לאיכות החיבור, המכונה מספקת בסיס טכנולוגי למנהיגות.

היא מאפשרת לייצרני ג׳יזבוס, פרגולות, טרסות ומבנים קשורים אחרים להתעלות על מגבלות הרכבה מסורתיות. על ידי איפשור יצירת חיבורים ארוכים, חזקים ומאומתים לחלוטין, היא מאפשרת לעסקים להתמודד עם פרויקטים גדולים יותר, להבטיח ביצועים מובילים של המוצר ולבנות מוניטין של איכות ללא פשרות.

לכל יזמה רצינית שמעוניינת לשלוט בשוק של ההגנות והצללים החיצוניים, שליטה בתהליך הלחימה היא עניין עיקרי. ה-RD-ZGHJ1200 של חברת Dongguan Ridong Intelligent Equipment מציע את האמצעים המדויקים, החזקים והיעילים להשגת שליטה זו, והופך את האתגר של חיבור בדילם ליתרון תחרותי ברור. זהו הכלי שמאפשר לכם לבנות מבנים שמתוכננים לא רק לעמוד, אלא גם להתקיים לאורך זמן.