When a homeowner looks for “motorized blackout roller blinds” or a builder searches “outdoor windproof patio screens,” speed and quality are everything. Today, fabricators and manufacturers in the window covering industry compete on lead time, flexibility, and flawless finish. Production lines buzz with smart machinery and digital controls, pushing boundaries on what “made-to-measure” really means.

This article breaks down where the curtain, blind, and outdoor shade manufacturing industry is heading in 2025 and beyond, why investing in the right machinery matters, and how Dongguan Ridong Intelligent Equipment Co., Ltd. helps factories stay ahead of the curve.

---

I. Industry Shifts: From Craft to Cutting-Edge Automation

The Move from Manual to Intelligent Production

Not long ago, curtain panels were mostly hand-sewn, roller blinds cut on band saws, and sunshades cobbled together with glue guns or basic welders. Skilled labor was vital, but so were off-cuts, long hours, and unpredictable results.

Now the industry is transformed by:

- Curtain Sewing Machines: CNC-controlled sewing units automate hems, pleats, and pockets with precise program settings. Single-operator stations can output 60–80% more panels daily.

- Roller Blind Cutting Machines: Servo-motor powered knife and ultrasonic systems cut textiles like polyester, fiberglass mesh, or PVC with ±0.1 mm accuracy. Barcode scanners ensure each blind matches its order spec—great for e-commerce and chain retail orders.

- Outdoor Sunshade and Insect Screen Machinery: High-frequency and hot air welders give seamless joins, strong enough for commercial use or windproof applications. Digital controls eliminate “human error” in weld strength and appearance.

Smart Features Now Standard

- Cloud-linked production: Machines track settings and batch data, syncing to your ERP for true “Industry 4.0” capability.

- Remnant optimization: Cut plans optimize material use in real-time, slicing waste and boosting the bottom line.

- Modular workstations: Lines expand or contract for short runs, batch orders, or custom sizes—all with just a tablet tap.

- Remote diagnostics: Real-time monitoring means issues get fixed fast, with most customer queries resolved online in under 30 minutes.

---

II. Why the Stakes Are Higher: Business Drivers in 2025

1. Speed is Money

Customers expect Door-to-Door delivery in days, not weeks. Shops selling “custom window shades online” now offer next-day dispatch. Delay equals lost orders.

- Fast changeover: Ridong’s machines are designed for rapid width and fabric swaps, letting you batch different orders in a single run.

- All-in-one lines: Hemming, cutting, welding—each integrated. No need for separate stations or labor-intensive transfers.

2. Quality Can’t Slip

Especially with reviews and social media feedback, quality problems hurt brands fast. A crooked stitch or weak weld? It goes viral.

- Laser-guided edge alignment means smudge-free hems and razor-sharp blind edges.

- PLC-controlled pressure and timing on welders keeps every join flawless, from blackout layers to sheer screens.

3. Customization & Lower MOQs

Hotels, home decorators, and even DIYers want unique designs, fabric prints, and exact sizes. This means more SKUs, shorter production runs, and a need to reconfigure lines quickly:

- Barcode-driven workflow: Pre-loaded cut files for every order, so “mix-and-match” is reality—no paper tickets, no confusion.

- Automatic label printing: Compliance for global retail (fire labels, composition, care labels) is done inline.

---

III. Niche Markets & Growing Opportunities

The curtain and blinds industry is booming in several specialty segments:

a. Smart Motorized Blinds and Curtains

Searches like “motorized curtain sewing machine” and “automated roller blind production line” are up 40% year-on-year as smart home trends take off. Ridong’s solutions integrate with motor-assembly, facilitate cable and rod passage, and guarantee repeatable, tight sewing for perfect fit.

b. Outdoor Windproof Shades

For cafe owners or property managers, “commercial-grade windproof patio screens” are essential. Machines must handle thicker mesh, apply strong welds, and create tension mounts:

- Extra-wide welding: Welder heads up to 10 meters for large patio or shopfront panels.

- PVC and Acrylic compatible: Specialized heat profiles prevent material yellowing and delamination.

c. Pet-Resistant Screens & Eco-Friendly Shades

With rising searches for “tear-resistant fiberglass screen mesh” and “PVC-free roller shades,” the demand for flexible machinery rises:

- Heat sealers for eco-safe polyester and PET textiles.

- Custom tape and edge-applicators that adapt to multiple mesh types for maximum durability.

d. Events & Rental (Glamping, Large Venues)

Manufacturers providing to the glamping and events sector need ultra-wide panels and tough, portable designs. Ridong’s heavy-duty cutters and welders support 3–15m wide tent panels and robust fixings.

---

IV. Dongguan Ridong’s Perspective: Where Is the Industry Heading?

Since its founding in 2007, Dongguan Ridong Intelligent Equipment Co., Ltd. has seen the industry go through dramatic change. With over 18 years focusing solely on window covering machinery, their view of the future is grounded in hundreds of real-world customer cases—from boutique startups to mega-factory OEMs.

Key Predictions & Advice from Ridong

1. Automation Will Continue.

- Labor supply is tightening worldwide. Smart factories aren’t just a bonus—they’re survival.

- Machine learning and AI will soon predict maintenance needs, manage production scheduling, and even “autotune” seam tension for each textile type.

2. End-Users Want “Instant Custom.”

- Expect batch sizes of 1–5 pieces to become the norm.

- Cloud-integrated machines allow web stores and POS directly linked to the factory floor.

3. Environmental & Quality Demands Will Tighten.

- “Zero-VOC blind welding machine,” “lead-free sunshade cutting,” and “anti-allergy curtain sewing system” are rising in B2B queries.

- Factories using efficient machines consume less energy, produce less waste, and win more contracts from eco-focused clients.

4. The China Advantage Remains, But with Upgrades.

- China continues as the hub for advanced curtain machinery, but simple low-priced machines will lose ground to flexible, digitally enabled solutions.

- Ridong invests heavily in R&D and support infrastructure—quick shipment of parts, online training, and 24/7 cloud troubleshooting.

Ridong’s ultimate vision: To help every curtain, blind, and sunshade factory in the world become as automated, scalable, and transparent as a top-tier electronics plant.

---

V. Products Leading the Change

As of 2025, these Ridong machines help hundreds of global clients meet their biggest challenges:

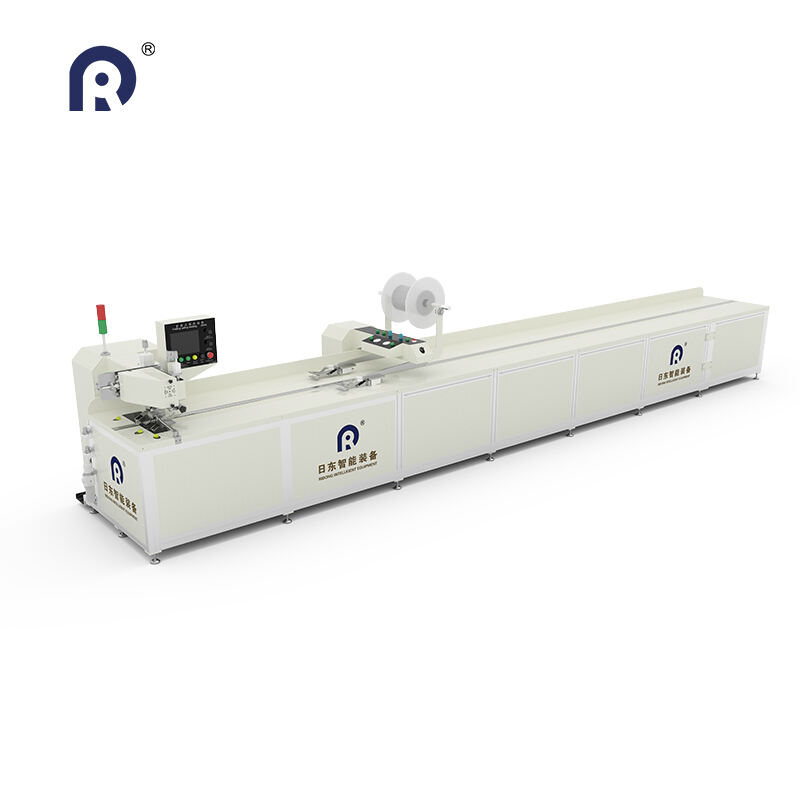

- RD-CQJ3260 Automatic Roller Blind Cutting & Sealing Line

- Process up to 95 blinds/hour with ±0.1 mm precision.

- Welds and seals in a single cycle; barcode input eliminates order errors.

- RD-PFJ400 Curtain Hemming Station

- Brother sewing machine head imported from Japan.

- No manual assistance is required, automatic sewing, with a back tension device, the backward pulling force can effectively avoid the problem of uneven hemming sewing stitches.

- RD-ZGHJ1200 High-Frequency Sunshade Welder

- Handles acrylic, PVC mesh, and glass-fiber textiles up to 10m width.

- Digital recipe storage for perfect repeatability.

- Custom Automated Production Lines

- Integrated modules for fabric feeding, edge taping, label printing, and order tracking.

All machines are designed for easy ERP, MES, and barcode integraton—no vendor-lock. Lifetime software upgrades and global parts supply keep production lines running at full speed.

---

VI. Real-World Results: Customer Voices & Case Studies

A. European Contract Supplier

Challenge: Meeting five-day lead times for 30+ sizes of blackout roller blinds for a hotel chain.

Solution: RD-CQJ3260 line with barcode tracking.

Result: 4x output, 2-person team, error rate dropped to <1%. Retained contract for repeat business.

B. US Home Renovation E-commerce Brand

Challenge: Frequent small-batch orders, high skill variance among sewing staff.

Solution: RD-PFJ400 programmable sewing machine with modular hem folders.

Result: Average panel time slashed from 12 minutes to under 90 seconds. Training time for new operator: 2 days.

C. Middle East Sunshade Producer

Challenge: Seam yellowing and glue delamination in +38℃ outdoor heat.

Solution: RD-ZPHJ1200 high-frequency hot air welding, digital temperature control.

Result: Zero complaints about seam discoloration; wins new contracts for luxury beach resorts.

D. Small Startup in Australia

Challenge: Competing with big factories on custom glamping tents and decks.

Solution: Custom automated line integrating fabric cutting, hot air welding, and digital order input.

Result: Doubled order capacity, 9-month ROI, won B2B clients from larger competitors.

---

VII. Ridong’s Commitment: Support That Truly Matters

At Ridong Intelligent Equipment, our core is “honest management, reliable quality, customer first.” What sets us apart?

- 48-hour global shipment of key spare parts.

- Remote training and support in English—get new staff up to speed quickly.

- Open SDK: Integrate Ridong machines with your local ERP, barcode scanner, or production dashboard.

- Lifetime software updates: Your machines improve every year.

---

VIII. Q&A – Real-World Pain Points and Ridong’s Solutions

Q1: Labor costs are high and skilled operators are hard to find. Will automation really reduce costs or just shift the problem?

A: Automation with Ridong’s sewing and blind machines lets you train new staff in days, not months. One operator can manage multiple machines. Most workshops cut their labor cost per unit by 40–60%, and remaining staff move to value-added tasks like inspection or packing.

Q2: We handle many custom sizes and colors. Can machines really keep up without mistakes?

A: Barcode-driven workflows, digital cut files, and auto-adjust fabric settings mean custom runs (even one-off orders) get correct processing every time. No missed hems, no mismatched sizes.

Q3: We lost money last year on small batch and short-run jobs. Can smarter machines improve this?

A: Ridong’s machines feature “remnant optimization.” They automatically nest multiple orders by width, reducing waste by up to 12%. Plus, fast changeovers keep lines running profitably even on short runs.

Q4: Our buyers complain about finish issues—yellowed welds, weak seams.

A: Digital control of heat, dwell time, and pressure ensures no scorching or yellowing. Seams meet European and North American specs for strength and appearance—essential for international clients.

Q5: After-sales service is slow with some equipment from abroad. How does Ridong support global clients?

A: 85% of customer issues are solved via online diagnosis in under 30 minutes. Critical spare parts ship DHL/UPS worldwide in under 48 hours. Lifetime software remote support ensures you’re always up to date.

Q6: Will new regulations on eco-friendliness or fire safety disrupt my factory?

A: Ridong machines are compatible with lead-free, PVC-free, and flame-retardant materials. Software updates are provided for any new welding or sewing parameters needed for certified fabric types.

Q7: How quickly do people see ROI?

A: Typical payback on new lines is 6–10 months, sometimes faster for high value-add custom work.

---

IX. Conclusion: Future-Proofing Your Fabrication with Ridong

The window covering industry will only get more competitive. With Ridong’s automation, every curtain, blind, or outdoor sunshade producer—no matter the scale—can ship faster, boost quality, lower costs, and win both big and small contracts.

Whether upgrading a single sewing table or planning a full “smart factory,” Ridong delivers reliability, flexibility, and real-world profit. Join the future of curtain and blind manufacturing—reach out today and discover what your next production chapter looks like.

---

For manufacturing leaders searching for “curtain sewing machine,” “roller blind production line,” “outdoor sunshade welder,” or “best curtain machinery China”—Ridong Intelligent Equipment is ready with the answers, support, and machines you need to win big in 2025 and beyond!