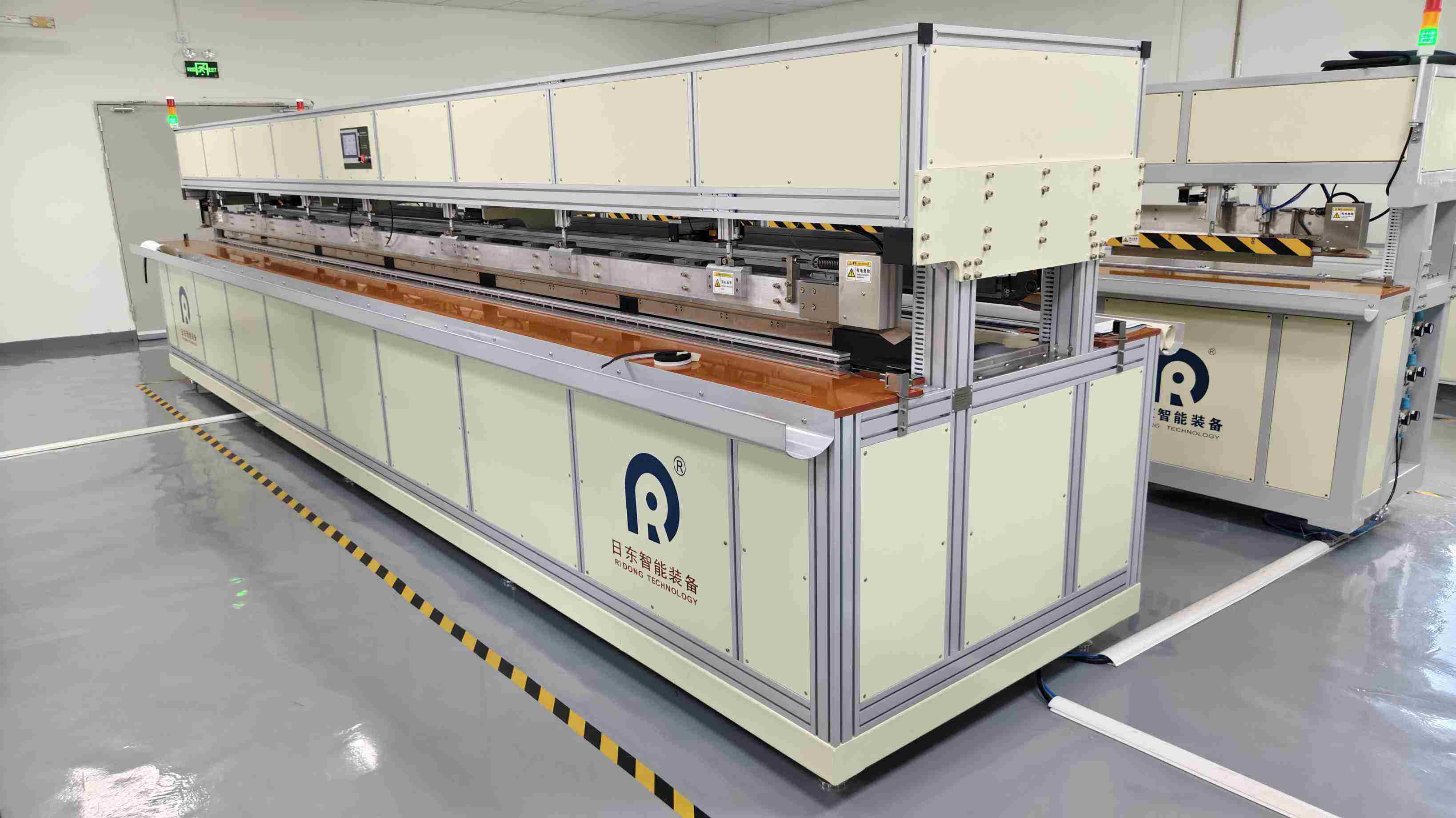

Dongguan Ridong's Revolutionary PVC Roll up Door Welding Machine: Setting New Standards for High-Speed Door Manufacturing

The relentless pace of industrial and commercial operations demands robust, reliable, and fast-acting solutions. High-speed PVC roll-up doors have become indispensable assets, safeguarding environments, controlling temperatures, and optimizing workflow efficiency across warehouses, manufacturing plants, clean rooms, and cold storage facilities globally. However, the critical component binding the performance and longevity of these doors – the PVC fabric curtain itself – has often relied on manufacturing processes vulnerable to inconsistency. Enter Dongguan Ridong Intelligent Equipment Co., Ltd. whose groundbreaking PVC High-Speed Door Fabric Welding Machine is poised to transform the industry by establishing unprecedented levels of precision, quality, and durability.

The Critical Weakness: Traditional Fabric Joining Methods

Historically, assembling the large panels of PVC-coated polyester fabric required for high-speed doors presented significant challenges:

1. Manual Hot-Air Welding: Highly dependent on operator skill, consistency, and environmental conditions. Prone to weak spots, inconsistent seam strength, porosity (air leaks), and visual imperfections. Labor-intensive and slow.

2. Adhesive Bonding: Concerns about long-term adhesion, especially under constant flexing and temperature variations. Potential for de-lamination, environmental impact of solvents, and curing times affecting production flow.

3. Mechanical Fastening (Stitching/Riveting): Creates puncture points inherently weakening the fabric, potential sites for tearing initiation, and compromising the crucial air-tight seal needed for insulation and containment. Not ideal for high-cycle doors.

These methods often resulted in curtains with variable performance characteristics. Seam failures, air leakage, reduced insulation properties, premature wear along stitch lines, and aesthetic flaws were not uncommon. This inconsistency directly impacted door reliability, energy efficiency, maintenance costs, and overall customer satisfaction, hindering the industry's ability to deliver uniformly high-performing products.

Ridong's Answer: Precision Automated Welding Redefined

Dongguan Ridong's innovative welding machine tackles these core weaknesses head-on, leveraging advanced automation and thermal control to deliver flawless, high-strength seams. Let's delve into the core technologies and advantages that set this machine apart:

1. Unmatched Seam Strength & Durability:

Technology: Utilizes highly controlled high-frequency (RF) or precision hot-wedge welding technology. RF welding generates heat internally within the PVC material itself through molecular friction, creating a true molecular bond across the entire seam width. Hot-wedge systems employ precisely heated elements melting the fabric surfaces under controlled pressure.

Advantage: Produces seams that are consistently stronger than the parent fabric material. Eliminates weak points associated with stitching or inconsistent manual welds. Seams withstand the extreme tensile forces and millions of flex cycles inherent in high-speed door operation without peeling or weakening. Dramatically reduces curtain failures and replacements.

2. Perfect Airtight & Watertight Seals:

Technology: The continuous, homogenous weld created fuses the PVC layers into a single, impermeable barrier across the entire seam length. No needle holes, no gaps, no porosity.

Advantage: Essential for maintaining temperature differentials in cold storage/freezer applications (preventing energy loss and ice buildup) and ensuring effective containment in cleanroom or dust-sensitive environments. Eliminates air leakage that can compromise door stability and performance. Enhances overall door efficiency and effectiveness.

3. Superior Consistency & Repeatability:

Technology: Full automation governed by sophisticated PLC (Programmable Logic Controller) systems. Precisely controls welding temperature, pressure, speed, and cooling time for every single seam, regardless of operator shift or day.

Advantage: Eliminates human error and variability. Every curtain produced meets identical, stringent quality specifications. Ensures predictable performance and longevity across all doors manufactured using Ridong-welded fabric. Builds brand reputation for reliability.

4. Significant Production Efficiency & Cost Savings:

Technology: Automated material handling, precise positioning, rapid welding cycles, and minimized setup times. Integrated cutting systems ensure perfect panel dimensions.

Advantage: Dramatically increases throughput compared to manual methods. Reduces labor costs per curtain significantly. Minimizes material waste due to precision and reduced rejects. Faster time-to-market for door manufacturers. Offers a compelling ROI.

5. Enhanced Aesthetics & Professional Finish:

Technology: Creates clean, narrow, and uniform seams. Precise control prevents burn marks, bubbling, or uneven surfaces common in manual processes.

Advantage: Produces curtains with a highly professional, visually appealing appearance. Consistent seams enhance the perceived quality and value of the final door product. Important for applications where aesthetics matter (retail, modern facilities).

6. Material Versatility & Adaptability:

Technology: Engineered to handle a wide range of PVC-coated polyester fabric weights, thicknesses, and formulations (e.g., standard, freezer-grade, fire-retardant, reinforced). Welding parameters are easily adjustable via the HMI (Human-Machine Interface).

Advantage: Provides manufacturers with unprecedented flexibility. A single machine can produce curtains for diverse door applications, streamlining production logistics and inventory. Future-proofs investment as fabric technologies evolve.

7. Improved Operator Safety & Ergonomics:

Technology: Enclosed welding areas, automated processes, reduced manual handling of heavy fabric panels, and elimination of open flames or high-risk adhesives.

Advantage: Creates a safer working environment, reducing the risk of repetitive strain injuries, burns, or exposure to fumes. Contributes to better workplace morale and reduced downtime.

Beyond the Machine: Catalyzing Industry-Wide Advancement

Ridong's innovation transcends simply selling equipment; it acts as a catalyst for elevating the entire high-speed door sector:

Establishing New Benchmarks: By enabling the production of curtains with consistently superior strength, sealing, and longevity, Ridong's machine sets a new, higher baseline for what constitutes a "quality" high-speed door curtain. Competitors must innovate or adopt similar technologies to remain relevant.

Enabling Higher Performance Doors: Reliable, airtight curtains are fundamental to achieving the high cycle speeds, insulation values (R-values/U-values), containment classifications, and wind resistance ratings demanded by modern facilities. Ridong's technology provides the foundation for next-generation door performance.

Reducing Total Cost of Ownership: While the machine represents an investment for fabricators, the downstream benefits are profound. End-users experience fewer door failures, reduced energy costs due to better sealing, lower maintenance requirements, and longer curtain lifespan.

Promoting Sustainability: Durable curtains that last longer reduce material consumption and waste. Energy-efficient doors contribute to lower carbon footprints for facilities. Precise manufacturing minimizes material scrap.

Driving Standardization: The consistency achievable with automated welding paves the way for more rigorous and measurable industry standards for seam strength, airtightness, and durability – standards that were difficult to enforce with manual methods.

Conclusion: A Watershed Moment for Door Fabrication

Dongguan Ridong Intelligent Equipment Co., Ltd.'s PVC High-Speed Door Fabric Welding Machine is far more than just a new piece of factory equipment. It represents a fundamental shift in the manufacturing paradigm for a critical component. By replacing inconsistent, labor-intensive, and potentially flawed joining methods with a process defined by precision, strength, airtightness, and repeatability, Ridong is empowering high-speed door manufacturers to deliver products of unparalleled reliability and performance.

This innovation directly addresses the core weaknesses that have plagued the industry, setting a new gold standard for quality. The advantages – from unmatched durability and perfect sealing to dramatic efficiency gains and enhanced safety – translate into tangible benefits for fabricators and end-users alike. Reduced operational costs, improved energy efficiency, fewer disruptions, and superior door performance become the new norm.

Ridong's commitment to intelligent manufacturing solutions is demonstrably raising the bar. Their welding machine is not merely an incremental improvement; it's a foundational technology enabling the next leap forward in high-speed door design, functionality, and value. Manufacturers embracing this technology are positioned to lead the market, delivering doors that consistently exceed expectations for durability, efficiency, and reliability, thereby shaping a more robust and higher-performing future for the entire industry. The era of inconsistent, weak-seamed curtains is ending, thanks to Ridong's pioneering vision.