Introduction

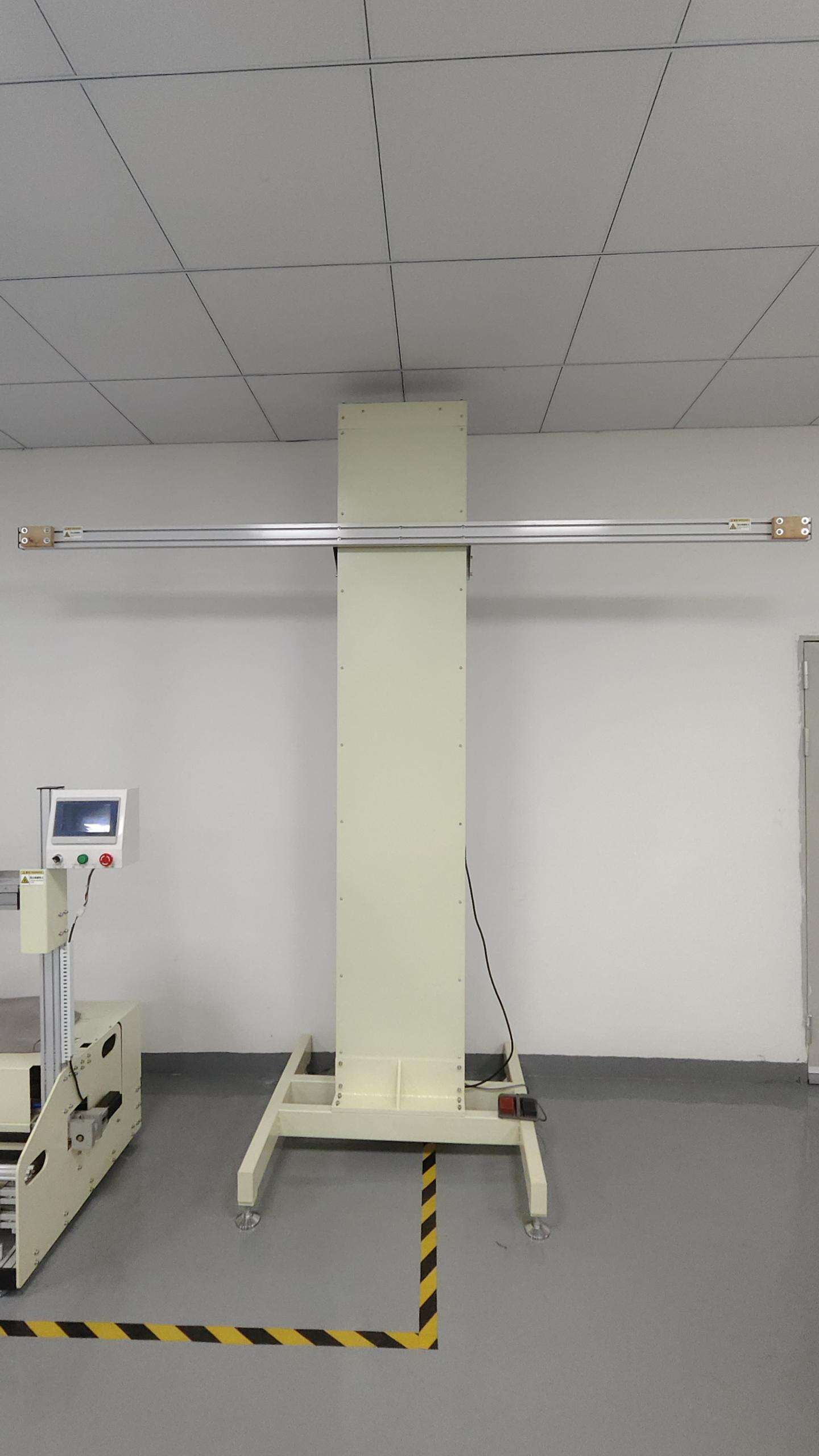

Blind inspection hoists are specialized quality control machines designed to test the functionality, durability, and safety of finished roller blinds and zip blinds. These hoists are critical in blinds manufacturing, ensuring that products meet stringent quality standards before reaching customers. Unlike general lifting hoists, blind inspection hoists are tailored for precise inspection tasks, allowing manufacturers to verify blinds performance in controlled environments. This guide provides a comprehensive overview of blind inspection hoists, covering their types, design features, applications, and selection criteria, with a focus on their role in blinds quality assurance.

---

Types of Blind Inspection Hoists

1. Electric Chain Hoist for Blinds Inspection

Overview:

Electric chain hoists are robust, automated systems ideal for inspecting heavy roller blinds and Windproof roller blinds. With a lifting capacity of up to 1.5 tons, they are suited for high-volume production environments.

Key Features:

- High lifting capacity for heavy blinds

- Low-noise operation for quiet inspection areas

- Continuous use capability for production lines

- Sturdy steel construction for durability

- Advanced safety features (e.g., overload protection, emergency stop)

Inspection Applications:

- Full roller blinds deployment and retraction testing

- Hardware functionality verification (e.g., rollers, tracks)

- Material strength and stitching quality checks

- Wind resistance simulation for specialized roller blinds

- Operational smoothness evaluation

Technical Specifications:

- Lifting speed: 3–5 m/min

- Power supply: 220V/380V AC

- Duty cycle: Continuous operation

- Safety factor: 4:1 minimum

2. Manual Chain Hoist (Block and Tackle) for Quality Control

Overview:

Manual chain hoists are cost-effective, portable solutions for small-scale or backup inspection tasks. With a lifting capacity ranging from 0.5 to 5 tons, they are versatile for various roller blinds sizes.

Key Features:

- Compact and lightweight design

- No power source required, ideal for remote workshops

- Easy setup and operation

- Reliable performance with minimal maintenance

- High-strength alloy steel chains

Inspection Applications:

- Small batch roller blinds inspection

- Prototype testing for new designs

- Custom roller blinds quality verification

- Component-level checks (e.g., hooks, slings)

- Backup for electric hoist systems

Technical Specifications:

- Chain length: Adjustable up to 10 meters

- Gear ratio: 3:1 to 6:1

- Safety factor: 4:1 minimum

3. Electric Wire Rope Hoist for Windproof roller blinds

Overview:

Electric wire rope hoists are designed for high-speed, heavy-duty inspection of Windproof roller blinds. With a lifting capacity of up to 10 tons and a speed of 8 m/min, they excel in rigorous testing scenarios.

Key Features:

- High lifting speed for efficient testing

- Smooth operation for precise inspections

- Harsh environment resistance (e.g., dust, humidity)

- Advanced safety features (e.g., dual braking, limit switches)

- Durable wire ropes for heavy loads

Inspection Applications:

- Wind load simulation testing

- Structural integrity verification

- High-strength material inspection

- Hardware durability testing

- Safety performance evaluation

Technical Specifications:

- Wire rope diameter: 12–24 mm

- Motor power: 3–15 kW

- Operating temperature: -20°C to +40°C

- Safety factor: 5:1 minimum

4. Lever Block Hoist for Detailed Inspection

Overview:

Lever block hoists are portable, hand-operated devices ideal for detailed roller blinds inspections. Their compact design makes them perfect for workshops with limited space.

Key Features:

- Easy operation for precise control

- Portable for flexible inspection setups

- Low maintenance requirements

- Reliable performance for small loads

- High-strength chain and hook system

Inspection Applications:

- Material quality verification (e.g., fabric, coatings)

- Stitching and seam integrity checks

- Hardware alignment and functionality testing

- Component-level quality assurance

- Visual defect identification

Technical Specifications:

- Lifting capacity: 0.5 to 3 tons

- Chain length: 3–10 meters

- Gear ratio: 4:1 to 8:1

- Safety factor: 5:1 minimum

5. Scissor Lift Inspection Hoist for Comprehensive Testing

Overview:

Scissor lift inspection hoists provide a stable platform for inspecting large blinds at height. They are ideal for comprehensive testing, including visual and functional assessments.

Key Features:

- Stable, spacious platform for inspectors

- Safety guardrails and emergency stop systems

- Overload protection for safe operation

- Smooth lifting for precise positioning

- Anti-slip platform for operator safety

Inspection Applications:

- Full blinds deployment and retraction testing

- Visual inspection of large roller blinds

- Hardware and track system verification

- Operational performance evaluation

- Safety feature testing

Technical Specifications:

- Platform size: 1.2 m x 1.5 m (typical)

- Maximum height: 6–12 meters

- Load capacity: 500–1000 kg

- Safety features: Emergency descent, overload sensors

---

Design Features for Roller blinds Inspection

Structural Design

Blind inspection hoists are engineered for precision and efficiency in blinds manufacturing workshops.

- Compact Footprint: Fits into tight spaces, ideal for small production facilities.

- Streamlined Shape: Minimizes space usage when idle, maintaining workshop aesthetics.

- Materials: High-strength steel or aluminum frames ensure durability, while corrosion-resistant coatings (e.g., powder coating, anodizing) protect against environmental wear.

- Ropes/Chains: Low-stretch, high-strength materials ensure stable and safe blinds handling during inspection.

Safety Systems

Safety is paramount in roller blinds inspection, protecting both operators and products.

- Overload Protection: Sensors halt operation if weight exceeds capacity.

- Emergency Stop Buttons: Immediate shutdown in critical situations.

- Automatic Braking: Secures the load during power failures or mechanical issues.

- Limit Switches: Prevent over-extension of lifting mechanisms.

- Safety Interlocks: Ensure safe operation during testing.

Control Systems

Precision control is essential for accurate roller blinds testing.

- Remote Operation: Allows inspectors to control the hoist from a safe distance.

- Wireless Controls: Enhances flexibility in workshop setups.

- PLC Integration: Enables automated testing sequences for high-volume production.

- Touchscreen Interfaces: Simplifies operation with intuitive controls.

- Programmable Settings: Customizes testing parameters for different blinds types.

Mechanical Systems

Robust mechanical systems ensure reliable performance during inspections.

- Chain/Wire Rope Drives: Provide smooth and controlled lifting.

- Hydraulic Cylinders: Offer precise movement for heavy blinds.

- Gear Reduction Systems: Enhance load-handling efficiency.

- Load Balancing: Ensures even distribution for accurate testing.

---

Quality Control Applications

Roller blinds Inspection

Blind inspection hoists verify the quality of standard roller blinds through:

- Material Testing: Checking fabric strength, tear resistance, and coating durability.

- Stitching Quality: Ensuring seams are secure and defect-free.

- Hardware Functionality: Testing rollers, tracks, and mounting systems.

- Operational Smoothness: Verifying ease of deployment and retraction.

- Visual Inspection: Identifying surface defects or manufacturing errors.

Windproof roller blinds Testing

Windproof roller blinds require specialized testing to ensure performance under extreme conditions.

- Wind Load Simulation: Testing resistance to simulated wind forces.

- Structural Integrity: Verifying frame and fabric durability.

- Hardware Durability: Ensuring components withstand high stress.

- Safety Performance: Confirming secure operation under load.

- Material Strength: Checking resistance to tearing or deformation.

Custom Roller blinds Inspection

For bespoke roller blinds, hoists provide tailored testing:

- Prototype Evaluation: Testing new designs for functionality and durability.

- Material Compatibility: Verifying performance of unique fabric combinations.

- Custom Hardware Testing: Ensuring specialized components meet standards.

- Performance Validation: Confirming operational requirements for specific applications.

---

Selection Criteria for Blind Inspection Hoists

Capacity and Weight Limit

Choose a hoist with a capacity that exceeds the heaviest blinds to be tested, ensuring a safety margin (e.g., 1.5x the maximum load).

Environment

Consider the workshop environment:

- Indoor/Outdoor Use: Outdoor hoists need weather-resistant coatings.

- Temperature/Humidity: Ensure compatibility with local conditions.

- Dust Protection: Critical for maintaining hoist longevity in dusty workshops.

Control System

Select a user-friendly system:

- Manual Controls: Suitable for small-scale operations.

- Semi-Automatic: Balances cost and efficiency.

- Fully Automatic: Ideal for high-volume production with precise testing needs.

Safety Features

Mandatory safety features include:

- Overload protection

- Emergency stop systems

- Backup braking mechanisms

- Compliance with industry standards (e.g., ISO, OSHA).

Durability and Build Quality

Opt for hoists with:

- High-quality materials (e.g., steel, aluminum)

- Corrosion-resistant finishes

- Robust mechanical components

- Long-term reliability

Ease of Maintenance

Choose hoists with:

- Accessible components for routine checks

- Clear maintenance guidelines

- Readily available spare parts

- Minimal downtime during servicing

Flexibility and Compatibility

Ensure the hoist:

- Integrates with existing workshop systems

- Adapts to various blinds sizes and types

- Offers customization for unique testing needs

Cost Considerations

Evaluate total cost of ownership, including:

- Initial purchase price

- Maintenance costs

- Energy consumption

- Potential downtime expenses

---

Maintenance and Care

Regular Maintenance

- Daily: Visual inspections for wear or damage.

- Weekly: Lubrication of moving parts.

- Monthly: Safety system checks and minor adjustments.

- Quarterly: Comprehensive mechanical inspections.

- Yearly: Full system calibration and overhaul.

Troubleshooting Guide

- Issue: Hoist fails to lift

- Check power supply or chain/wire rope alignment.

- Verify load is within capacity.

- Issue: Unusual noises

- Inspect for loose components or lack of lubrication.

- Schedule professional service if persistent.

- Issue: Safety system errors

- Reset and test overload sensors or limit switches.

- Consult manufacturer for calibration.

---

Expanded Q&A: Everything You Need to Know About Blind Inspection Hoists

Q1: What is a blind inspection hoist?

A1: A blind inspection hoist is a specialized quality control machine used to test the functionality, durability, and safety of finished roller shade and Windproof roller blinds. It ensures blinds meet quality standards before market release.

Q2: What are the key features of a blind inspection hoist?

A2: Features include high lifting capacity, smooth operation, advanced safety systems (e.g., overload protection, emergency stop), precise control systems, durable construction, and compact design for workshop integration.

Q3: Where can one find a blind inspection hoist?

A3: Ridong are roller blind and curtain machine manufacturer over 17 years, we can provide all kinds of roller blinds, curtains, outdoor sunshade, windproof roller blind machines. We can also customize blind inspection hoist

Q4: What is the use of a blind inspection hoist?

A4: Blind inspection hoists are used in blinds manufacturing to verify product quality through:

- Material and stitching integrity checks

- Hardware functionality testing

- Wind resistance evaluation

- Operational performance validation

- Visual defect identification

Q5: What are the advantages of using a blind inspection hoist?

A5: Advantages include:

- Ensures consistent product quality

- Reduces customer returns and complaints

- Verifies compliance with safety standards

- Enhances production efficiency

- Supports rigorous wind resistance testing

- Minimizes defects through thorough inspection

Q6: What types of blinds can be inspected with these hoists?

A6: Blind inspection hoists can test:

- Standard roller blinds

- Windproof roller blinds

- Custom-designed roller blinds

- Heavy-duty industrial blinds

- Blinds with specialized features (e.g., UV resistance)

Q7: How often should a blind inspection hoist be maintained?

A7: Maintenance schedules include:

- Daily visual checks

- Weekly lubrication

- Monthly safety inspections

- Quarterly mechanical reviews

- Annual calibration and servicing

Q8: Can blind inspection hoists be customized for specific needs?

A8: Yes, hoists can be customized with:

- Adjusted lifting capacities

- Specialized control systems

- Enhanced safety features

- Integration with production lines

- Tailored testing parameters

Q9: How do blind inspection hoists ensure operator safety?

A9: Safety is ensured through:

- Overload protection systems

- Emergency stop and braking mechanisms

- Limit switches to prevent over-extension

- Safety interlocks and guardrails

- Operator training and safety protocols

Q10: What factors influence the cost of a blind inspection hoist?

A10: Cost factors include:

- Lifting capacity and hoist type

- Automation level (manual vs. automatic)

- Safety feature complexity

- Customization requirements

- Maintenance and operational expenses

---

Conclusion

Blind inspection hoists are indispensable in the roller blinds manufacturing industry, ensuring that roller blinds and zip blinds meet high quality and safety standards. By understanding the types, features, and applications of these hoists, manufacturers can select the right equipment to enhance production efficiency and product reliability. With proper maintenance and adherence to safety protocols, blind inspection hoists deliver long-term value, supporting consistent quality control and customer satisfaction.