The External Screen Welding Machine, also known as the Zip Screen Welding Machine, represents the latest advancement in window screen manufacturing technology. This state-of-the-art equipment is specifically designed to handle various welding requirements for external window screens and roller blinds with exceptional precision and efficiency.

Description

Advanced External Screen Welding Machine: Precision & Versatility in Window Screen Manufacturing

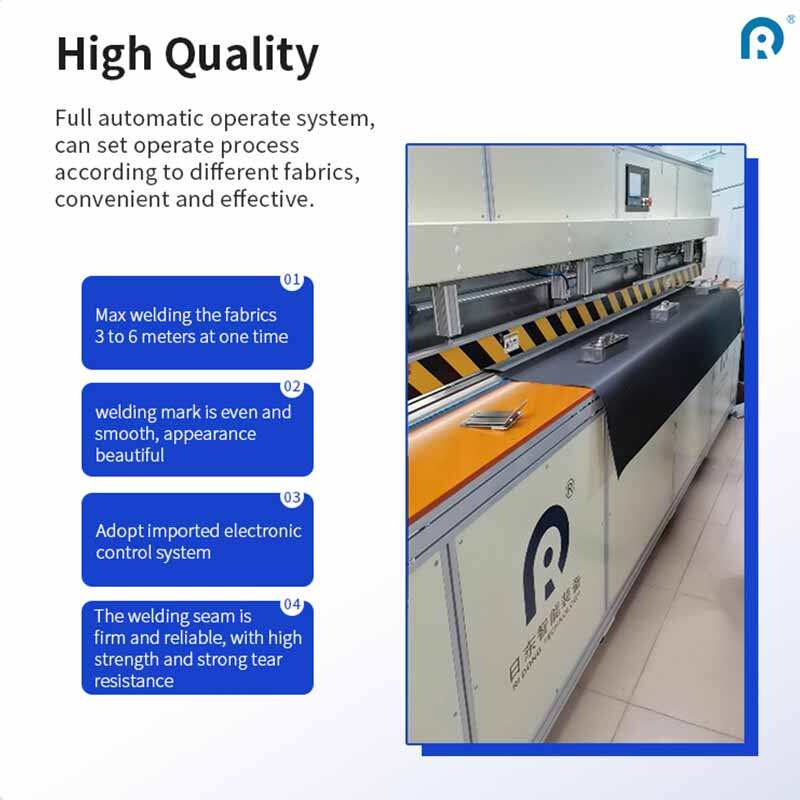

Key Features & Advantages

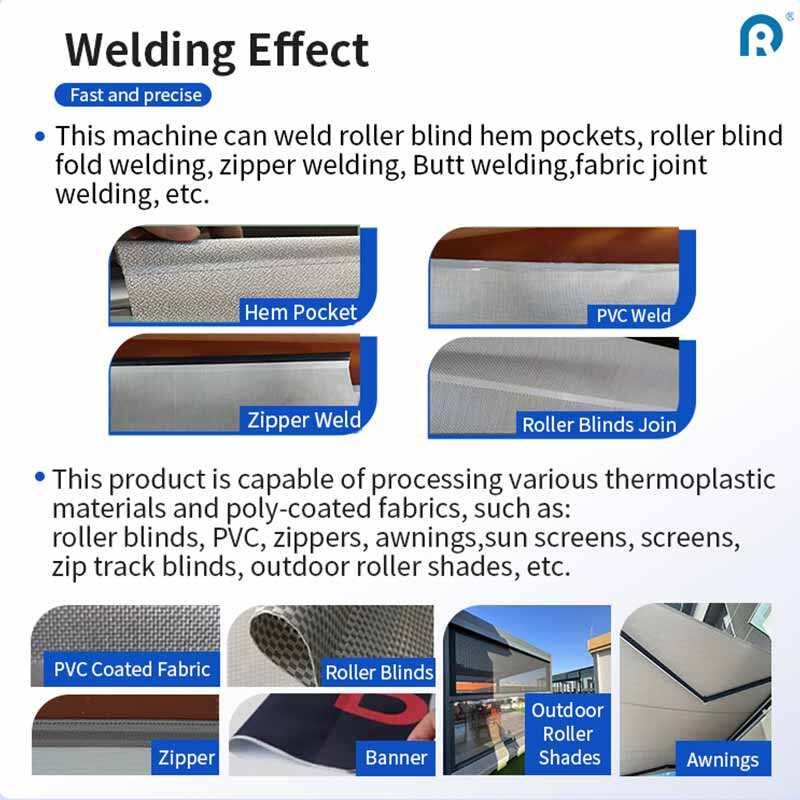

1. Versatile Welding Capabilities

- Primary function: Welding zip screen zippers with customizable lengths (standard 6m, customizable up to 15m)

- Capable of welding various materials:

- Rubber strips

- Plastic strips

- Cylindrical rubber strips

- Ideal for fabricating external zipper window screens

2. Material Compatibility

- Optimized for PVC and PE fabrics

- Large welding area ensures robust connections

- Excellent tear resistance for long-lasting durability

- Customizable welding length and width to meet specific requirements

3. Precision Engineering

- High-precision welding technology for consistent results

- Adjustable welding parameters for different material thicknesses

- Smooth operation with minimal material distortion

- Quick changeover between different welding configurations

Applications & Benefits

The External Screen Welding Machine is particularly well-suited for:

- Window screen manufacturers requiring high-quality zipper attachments

- Custom blind makers needing precise welding capabilities

- Textile processing facilities working with technical fabrics

- Outdoor screen manufacturers requiring durable welding solutions

Key benefits include:

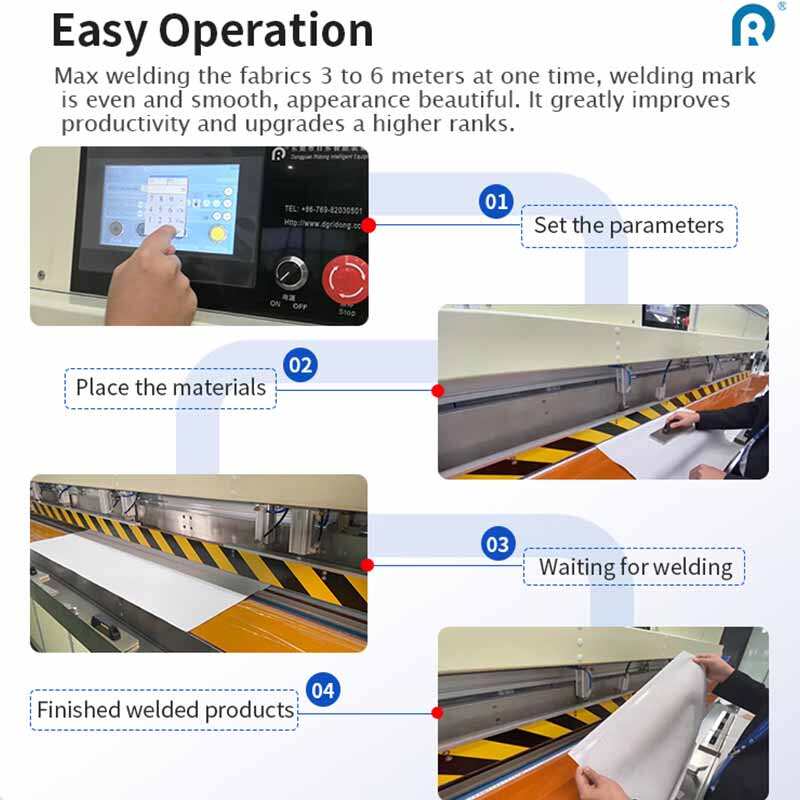

- Increased productivity through automated welding processes

- Consistent quality with minimal operator intervention

- Versatility in handling various fabric types and thicknesses

- Reduced material waste through precise welding control

- Customizable welding parameters for specific application needs

Technical Specifications

- Standard welding length: 6m (customizable up to 15m)

- Material compatibility: PVC, PE, and other compatible fabrics

- Welding area: Large coverage for robust connections

- Customization options: Adjustable welding length and width

- Safety features: Operator protection and emergency stop controls

Industry Applications

This Roller Blinds Welding Machine is ideal for:

- External window screen manufacturers

- Custom blind fabrication shops

- Outdoor screen production facilities

- Technical textile processing plants

The Zip Screen Welding Machine represents a significant advancement in window screen manufacturing technology, offering unparalleled precision, versatility, and efficiency. It's the perfect choice for manufacturers looking to enhance their production capabilities while maintaining the highest quality standards in external screen welding applications.

Parameter

| Machine model | RD-HJJ600F |

| Welding size | 6M |

| Welding mark | 8.0/12.0mm |

| Rated voltage | 220/110VAC50/60Hz |

| Rated power | 4.3KW |

| Machine Size | 6660*702*1650mm |

| Machine weight | 1200KG |