The Critical Role of Awnings Sewing Machines in Outdoor Fabric Durability

How Awnings Sewing Machine Technology Supports Durable Outdoor Structures

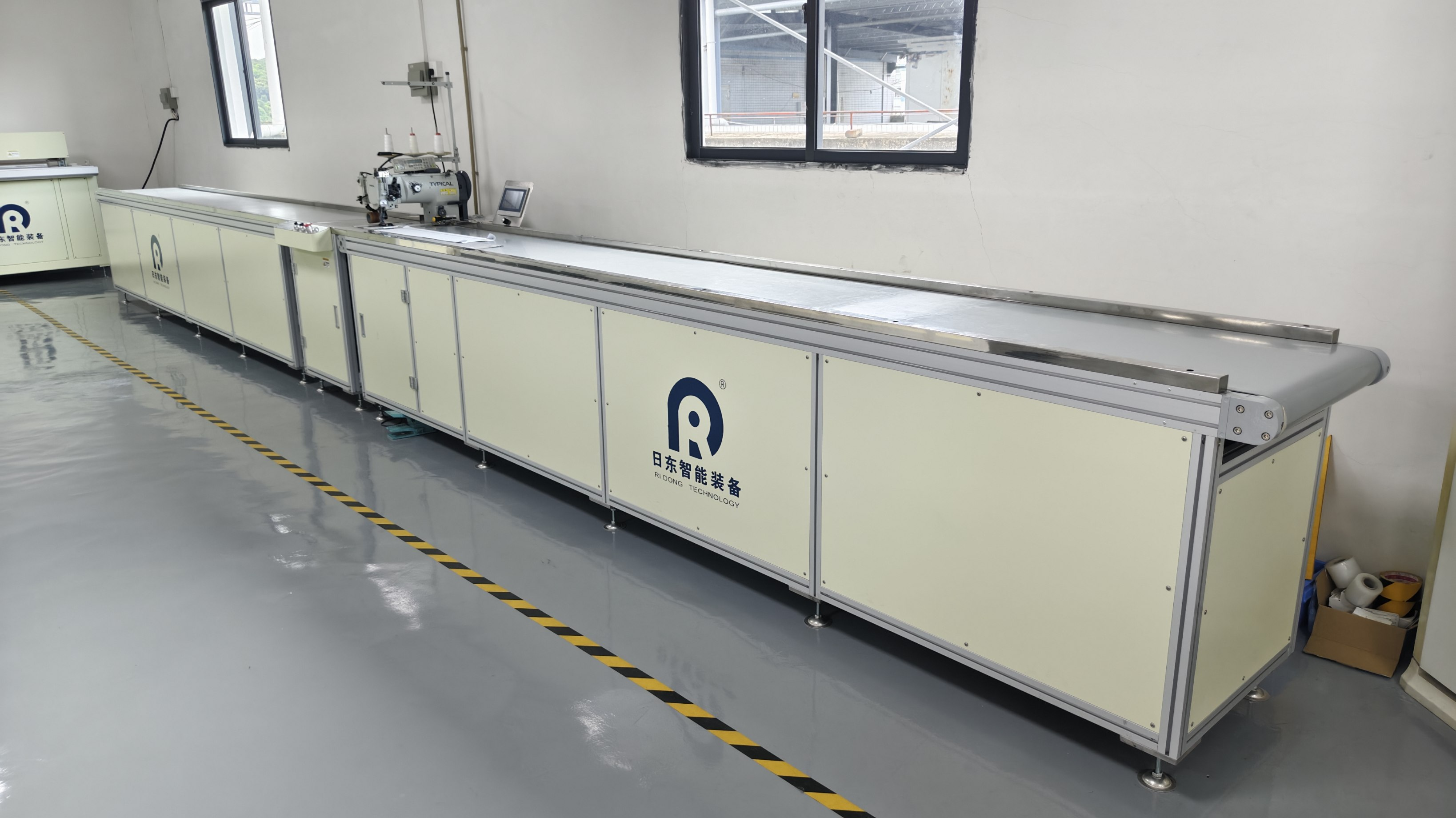

The industrial sewing machines used for awning production offer the kind of mechanical accuracy needed to create strong seams that hold up outdoors where conditions can be tough. These machines aren't like regular home models at all. They keep the needles going through thick materials such as acrylic fabrics and vinyl laminates consistently, which means the seams they produce can handle winds over 60 miles per hour according to ASTM standards from 2023. The feed mechanism is reinforced so fabric doesn't slip during stitching, making sure every part of the awning has equally strong seams throughout. All this engineering work pays off when it comes to keeping out bad weather because the tight stitches actually stop water from getting in those spots where stress tends to build up most.

Key Differences Between Standard and Heavy-Duty Sewing Machines in Outdoor Fabric Applications

Knowing the difference between regular and heavy duty sewing machines really matters when dealing with those tough outdoor fabrics. The industrial grade machines used for awnings have these strong servo motors that can handle over 1,200 stitches each minute while maintaining steady power, compared to home models which usually max out around 800 stitches per minute and start struggling when things get heavy. Industrial units come with bigger needles ranging from size 18 to 22 instead of the smaller 14 to 16 sizes found on household machines. They also feature special feed dogs that actually grab onto thick materials without stretching them out of shape. What makes these machines truly stand out though are their walking feet or compound feed systems. These components stop multiple layers of fabric from moving around while stitching, something that causes lots of broken seams in regular machines that weren't built for this kind of work.

Industry Demand for Precision: Why the Awnings Sewing Machine Is Indispensable

For commercial awning makers, getting those stitches just right matters a lot when it comes to how long products last and what happens with warranties down the road. Industrial sewing machines used for awnings can keep stitch lengths consistent within about 0.1 millimeters, which beats out regular equipment that usually has around 0.5mm variation between stitches. When seams are stitched accurately like this, stress gets spread out evenly instead of concentrating in one spot, so there's less chance of tears forming when winds pick up. Getting thread tension right through all those fabric layers also stops those annoying loose stitches that let water seep through over time. Because of these features, most pros stick with specialized machinery for their work since the structural strength of an awning really does impact both customer satisfaction and potential legal issues if something fails after installation.

Data Insight: 78% of Commercial Awning Manufacturers Prioritize Industrial-Grade Sewing Equipment

According to industry research from IFAI 2024, around three out of four commercial awning makers have industrial sewing gear as top priority for their shops. The numbers tell the story pretty clearly too. Industrial machines just don't fail at seams as often during those harsh weather tests they run in labs. We're talking about 40 percent less problems than when people try to modify regular commercial machines instead. And real world results match this trend. Shops that stick with purpose built awning sewing machines see way fewer warranty issues because of seams coming apart. About 62 percent reduction over five years actually. All these stats point to one thing really. When companies invest properly in good equipment upfront, they end up with better products down the road in the professional awning business.

Sewing vs Sealing for Awnings: Comparing Long-Term Structural Performance

Strengths and weaknesses of sewing vs sealing for awnings in real-world installations

When it comes to making awnings, there are basically two ways to join materials together - sewing versus sealing - and they each have their own strengths and weaknesses. Sewn seams get made on special machines designed specifically for awning fabrics. These seams hold up pretty well mechanically and allow the fabric to move naturally when winds blow through. But here's the catch: those tiny holes from the needles let water sneak in over time and can also speed up UV damage to the fabric. On the other side of things, sealed or welded seams actually melt the materials together without any holes at all. This creates completely watertight connections that beat sewn ones hands down when it comes to keeping moisture out. The downside though? Welded seams don't flex as easily. They stand up better against harsh weather conditions, sure, but aren't so great for situations where the fabric needs to stretch or shift around much.

Case study: Performance comparison of sewn versus heat-sealed joints after 3 years of UV exposure

Researchers conducted a three year field test looking at how different types of awning joints hold up when exposed to sunlight over time. The findings revealed something interesting about heat sealed connections versus traditional sewn ones. After sitting out there for 36 whole months, those heat sealed seams still kept around 94 percent of their ability to keep water out. Meanwhile, the sewn joints lost about a quarter of their waterproof qualities. But wait, there's another side to this story. When it comes to flexibility, sewn joints actually performed better in real world conditions. They showed roughly 18% less strain on the corners during those big windstorms we all dread. So what does this mean? Well, if keeping things dry for years matters most, then heat sealing makes sense. But for installations where the fabric needs to move naturally without tearing at the edges, old fashioned sewing still has its place in certain applications.

Heavy-Duty Sewing Machines: Enhancing Seam Strength in Outdoor Fabrics

Use of heavy-duty sewing machines in outdoor fabrics: Mechanical advantages and seam integrity

When it comes to outdoor fabric work, industrial awning sewing machines bring real mechanical benefits to the table. These machines have those heavy duty frames plus fancy feed systems that keep seams lined up even when dealing with thick materials. The walking foot feature is actually pretty cool because it stops the fabric from moving around while stitching, which makes all the difference when working with those tricky coated fabrics or laminates that tend to slide. What does this mean in practice? Stronger seams that hold up against serious weather conditions. Most industrial models can handle wind forces of around 90 mph as per ASTM specs, so they're built tough enough for real world use. And let's face it, the solid build quality means these machines can run non-stop through big production runs without compromising on stitch quality, which is exactly what manufacturers need when making hundreds of awnings each week.

Higher stitch-per-minute rates and needle penetration power in industrial systems

When it comes to sewing systems, industrial machines just plain beat out what's available for home use in almost every way that matters. Take those heavy duty awning sewing machines for instance they can crank out around 1500 to 2500 stitches per minute, while even the best home models only manage about 800 to 1000 stitches. That kind of difference really adds up when running a production line. Manufacturers report getting big jobs done roughly 40% quicker with these industrial beasts. And let's not forget about the muscle behind them either. Industrial motors pack anywhere from 30% to maybe even 50% more punch when pushing the needle through material. This means workers can stitch right through several layers of thick canvas or vinyl without breaking a sweat. The result? Seams that hold up against harsh weather conditions year after year, something regular home sewers simply cant match.

Controversy Analysis: Are heavier machines always better for lightweight technical fabrics?

Heavy duty machines work great on regular awning materials but can be problematic when dealing with lightweight technical fabrics. The same needle force that's good for thicker stuff might actually push through or damage really light materials. We've seen some problems where old school heavy machines punch too many holes in fabrics lighter than about 8 ounces per square yard. Fortunately, newer industrial equipment comes with adjustable presser foot settings and different needle options. These adjustments let operators work with all kinds of fabric weights without constantly switching machines. What this means for shops is simple: don't just grab the biggest machine available. Take time to match the right settings to what's actually being sewn. Sometimes lighter isn't worse after all.

Integrating Waterproofing Techniques with Industrial Sewing Systems

Waterproofing techniques in awning fabrication: Seam taping and coating integration

Waterproofing awnings really comes down to dealing with those weak spots where the seams are sewn together. Industrial sewing gives the structure what it needs to hold up, but all those tiny holes from the needles let water sneak through eventually. Smart companies solve this problem by adding seam tape, which is basically heat activated stuff that creates a solid wall right over those stitched areas. They also use different kinds of fabric coatings like polyurethane or acrylic treatments to make the material itself less likely to absorb water. The numbers back this up too - studies show good seam taping cuts down on water getting in by around 92% when compared to regular seams without any treatment according to the Outdoor Fabric Waterproofing Report from last year. Most professionals now stick with this two step method first sew then seal because it just works better for keeping fabrics dry and lasting longer outdoors.

Trend: Rise of hybrid sewing-taping machines in high-volume awning production

More textile factories are now switching to these combo sewing and taping machines that handle both stitching and sealing all at once. The old way had sewing done separately from waterproofing, which really slowed things down. According to the Industrial Textile Production Review from last year, this new approach can speed up production by about 40%. When the machine keeps those tapes lined up exactly with the stitches, it cuts down on mistakes people used to make manually. Big manufacturers making tons of product every day have jumped on board with this tech because they need to crank out more goods while still keeping quality consistent. It's a real game changer compared to what was happening before when workers had to do sewing and then later apply tape as completely separate tasks.

Strategy: Optimizing stitch patterns to minimize water ingress without compromising flexibility

Choosing the right stitch pattern is all about finding that sweet spot between keeping water out and letting the fabric move naturally. Zigzag stitches pack in more needle holes which actually helps adhesive tapes stick better, but straight stitches minimize those entry points at the cost of weaker seals. Most modern sewing machines for awnings come with settings that let manufacturers tweak this balance just right, usually running around 8 to 12 stitches per inch to stop water from sneaking through without making everything too stiff. We're seeing triple step patterns become pretty popular lately because they overlap the needle tracks, creating barriers against water infiltration. Combine this with good quality threads and tight tension settings, and the resulting seams can handle brutal weather conditions while still allowing the awning material to flow and flex properly when needed.

FAQ

Q: What is the primary advantage of industrial awning sewing machines?

A: Industrial awning sewing machines provide mechanical accuracy to create strong seams that withstand harsh outdoor conditions, ensuring durability and protection against the elements.

Q: Why are heavy-duty sewing machines essential for outdoor fabrics?

A: Heavy-duty sewing machines feature powerful motors and specialized components such as walking feet, ensuring that thicker materials are sewn consistently and with integrity.

Q: How do sewing and sealing differ in awning construction?

A: Sewing involves creating seams that flex with the fabric, allowing ease of movement, while sealing offers watertight joints, preventing moisture ingress but may limit flexibility.

Q: Are heavy-duty machines suitable for all fabric types?

A: While ideal for thicker materials, heavy-duty machines may damage lightweight technical fabrics if not adjusted properly. Newer models include settings to accommodate various fabric weights.

Table of Contents

-

The Critical Role of Awnings Sewing Machines in Outdoor Fabric Durability

- How Awnings Sewing Machine Technology Supports Durable Outdoor Structures

- Key Differences Between Standard and Heavy-Duty Sewing Machines in Outdoor Fabric Applications

- Industry Demand for Precision: Why the Awnings Sewing Machine Is Indispensable

- Data Insight: 78% of Commercial Awning Manufacturers Prioritize Industrial-Grade Sewing Equipment

- Sewing vs Sealing for Awnings: Comparing Long-Term Structural Performance

- Heavy-Duty Sewing Machines: Enhancing Seam Strength in Outdoor Fabrics

- Integrating Waterproofing Techniques with Industrial Sewing Systems