Why Manufacturers Are Adopting the Insect Screen Welding Machine

Rising Global Demand for Mosquito Nets and the Limits of Manual Welding

The worldwide need for mosquito nets has shot up because governments and organizations are pushing harder against diseases carried by insects, particularly in areas where malaria is common. People living in tropical regions have become much more aware of how important these simple protective tools really are. But here's the problem: old school welding techniques just can't handle this increased demand anymore. These traditional methods slow things down at every stage of production. The joints aren't always strong enough or last as long as they should, which means lots of rejected products and wasted materials. And let's face it, when different workers do the same job differently, quality control becomes a nightmare. This inconsistency makes scaling operations really tough for manufacturers trying to meet big orders from international buyers or respond quickly when there's an emergency situation requiring thousands of nets overnight.

Core Advantage: Precision Resistance Welding for Consistent, Seam-Free Mesh Joints

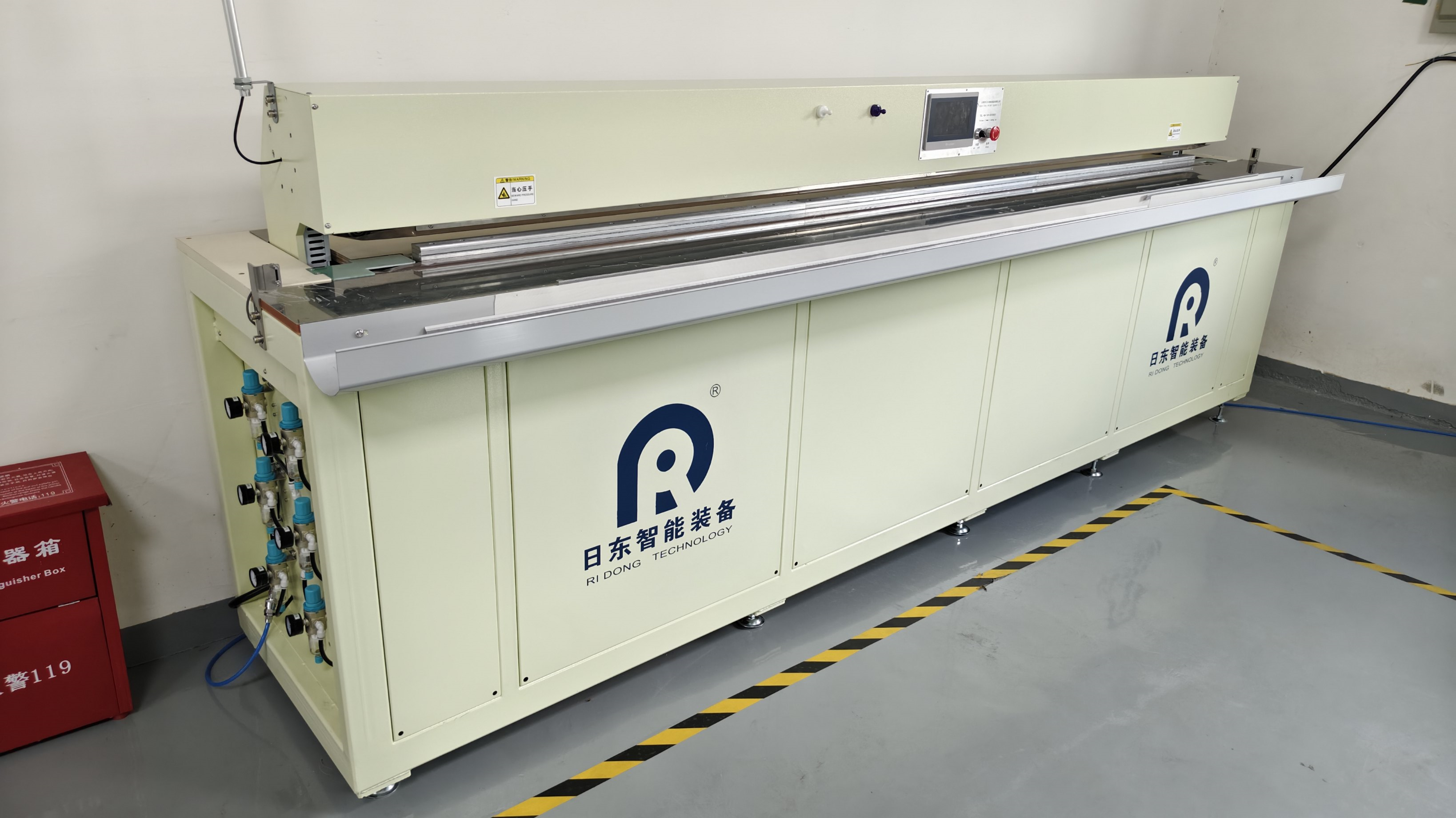

Insect screen welding machines work their magic through precision resistance welding techniques, creating those neat, seamless connections where wires cross paths in mesh screens. When the machine applies just the right amount of electrical current, it creates enough heat to melt the wires together while keeping those protective coatings intact. That means no loss of corrosion protection or weakening of the overall structure. The whole system is automated so parameters stay consistent across all welds, which cuts down on mistakes people might make when doing this manually. We're talking about consistent strength, proper alignment, and good penetration resistance every single time. For manufacturers dealing with quality control issues from hand welding, these machines represent a real solution to problems that have plagued the industry for years.

Measurable Gains in Production Efficiency from the Insect Screen Welding Machine

Output Uplift: Case Evidence – 68% Higher Throughput in Ghanaian Facility

A small net factory in Ghana saw their daily production jump by almost two thirds when they swapped out old manual welding techniques for a new automated insect screen welding machine. What makes this system work so well is how it combines cutting and welding processes seamlessly, allowing workers to keep going nonstop without those annoying pauses between stages. This means they can respond much faster when there's urgent need for mosquito nets during disease outbreaks or other public health crises. The boost in productivity also cuts down on what each net costs to make, both in terms of labor and running expenses. As a result, more communities get access to quality mosquito nets while still meeting strict quality standards and keeping shipments on schedule despite increased demand.

Quality & Reliability: 92% Reduction in Weld Variability (ISO 15614-1 Validated)

Feedback systems that are automated keep adjusting those key welding parameters throughout the process. We're talking about things like electrode force ranging between 250 to 300 Newtons, weld currents hitting around 8,500 up to 9,200 Amps, and squeeze times clocking in at just 30 to 40 milliseconds. These adjustments help maintain good quality work no matter what shift it is or which batch they're working on. Tests done according to standards set by ISO 15614-1 show these systems cut down weld variations by almost 92 percent when compared with old fashioned manual techniques. Fewer problems mean we see much less issues with weak seams, parts burning through during welding, or mesh getting distorted. Products last longer too. For people actually using them, the screens stay stable in size and shape while still keeping insects out even when exposed to all sorts of weather conditions and other stresses found in everyday environments.

Strategic Integration: Embedding the Insect Screen Welding Machine into Existing Lines

Modular Retrofitting Without Line Shutdown

Insect screen welding machines are built to work without needing complete line stoppages during installation. The machines come with standard mechanical parts and communication ports that just fit right into old conveyor systems, PLC controls, and other equipment already in place at most facilities. Plants don't have to overhaul everything all at once. They can fix up one section at a time while keeping the rest running normally. This kind of setup actually protects against big financial losses and gets returns on investment much faster. Mid sized manufacturing operations find this particularly helpful when they want to grow their business but still need to maintain regular production schedules without major disruptions.

Synchronized Workflow: Bridging Automated Cutting, Feeding, and Welding Stages

Modern systems work seamlessly with automated cutting tables and feeding mechanisms through constant data sharing and connected sensors throughout the production line. This setup keeps materials perfectly positioned and maintains even tension right before the welding process starts, which cuts down on the need for workers to handle things manually at different points in the workflow. Industry data from textile manufacturing shows these synchronized processes can slash handling mistakes by as much as 85 percent. What this means for manufacturers is a completely integrated workflow from start to finish. The system preserves the shape of the mesh and ensures accurate joints even after running through thousands of production cycles, all while requiring minimal input from operators day to day.

Long-Term Operational Benefits Beyond Speed

The insect screen welding machine does more than just boost efficiency right away. It actually lays the groundwork for sustainable growth focused on quality. The machine cuts down on rework because it's so precise, and we waste way less raw materials too. Plus, when demand spikes, the automated system can handle it all without needing tons of extra workers. Meeting those international standards like ISO 15614-1 and WHO prequalification isn't just paperwork. It really opens doors to bigger contracts around the world and gets products into better supply chains. Manufacturers who invest in this tech see benefits beyond just producing more stuff. Their brands become more trustworthy, they maintain better profit margins even during tough times, and stay competitive in markets where customers won't settle for anything less than proven quality anymore.

FAQs About Insect Screen Welding Machine

What is an insect screen welding machine?

An insect screen welding machine is an automated device that uses precision resistance welding techniques to seamlessly join wires in mesh screens, ensuring consistent strength and protection without manual intervention.

How does the insect screen welding machine improve production efficiency?

These machines enhance efficiency by automating the welding process, reducing human errors, and enabling continuous operation. This leads to faster production, reduced labor costs, and higher throughput.

Why is modular retrofitting advantageous for manufacturers?

Modular retrofitting allows manufacturers to integrate new welding machines into existing production lines without complete shutdowns, minimizing disruptions and financial losses while promoting gradual upgrades.

Table of Contents

- Why Manufacturers Are Adopting the Insect Screen Welding Machine

- Measurable Gains in Production Efficiency from the Insect Screen Welding Machine

- Strategic Integration: Embedding the Insect Screen Welding Machine into Existing Lines

- Long-Term Operational Benefits Beyond Speed

- FAQs About Insect Screen Welding Machine