The Complete Guide to Roller Blind Welding Machines: Types, Applications & Industry Solutions

The production of roller blinds requires an understanding of the diversity of machines employed in the operation. A key part of fabricating roller blinds, welding machines, which offer different automatic, semi-automatic, and manual welding options, cater specifically to the material and design requirements of the blinds. This section delineates the nuances of these types and their impact on operation.

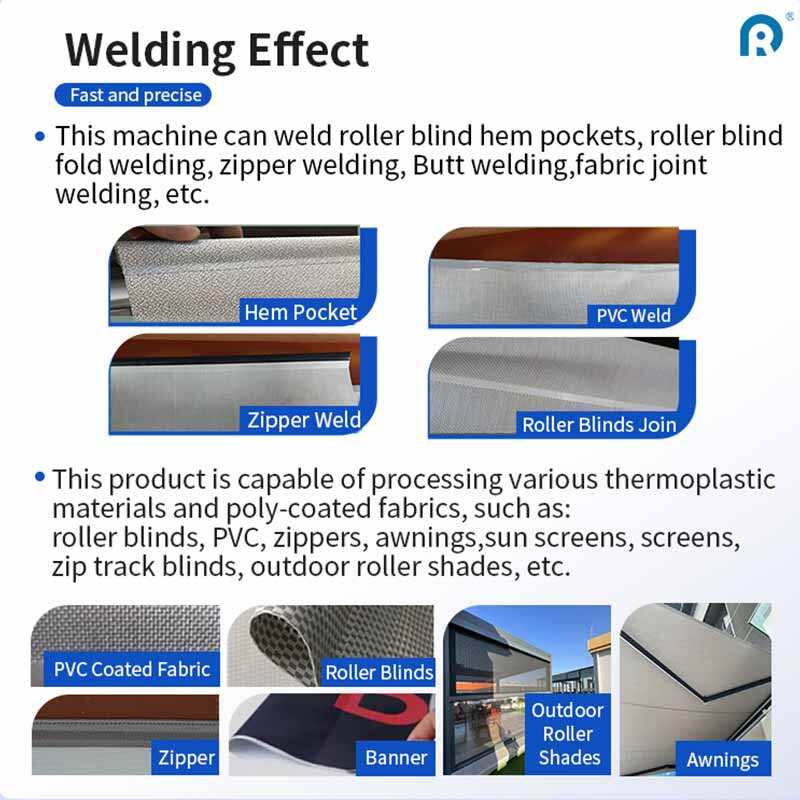

Understanding Roller Blind Fabric Welding Technology

Roller blind welding machines use controlled heat to fuse fabric layers, creating seamless, waterproof joins that outperform traditional sewing. These fabric welding solutions have revolutionized blind manufacturing by enabling:

- Stronger, fray-resistant seams

- Waterproof construction

- Faster production speeds

- Consistent quality output

Core Welding Methods:

|

Method |

Temperature Range |

Best For |

|

Hot Air |

300-500°C |

PVC-coated fabrics |

|

High Frequency |

100-200°C |

Thermoplastics |

|

Ultrasonic |

150-300°C |

Synthetic blends |

Types of Welding Machines for Different Production Needs

1. Automatic Roller Shade Welding Machines

- Operation: Fully computerized with programmable patterns

- Output: 100-150 blinds/hour

- Best For: Large manufacturers producing >5,000 units/month

- Key Advantage: Consistent precision with minimal supervision

2. Semi-Automatic Zip Blinds Welding Machines

- Operation: Automated welding with manual material feeding

- Output: 40-120 blinds/hour

- Best For: Custom shops producing 500-5,000 units/month

- Key Feature: Quick-change tooling for different blind types

3. Manual Fabric Welding Machines

- Operation: Hands-on control with foot pedal activation

- Output: 10-30 blinds/hour

- Best For: Interior designers & small workshops (<500 units/month)

- Training Required: <2 hours for basic operation

Industry-Specific Machine Recommendations

|

Industry |

Production Volume |

Recommended Machine |

Fabric Types |

Special Features Needed |

|

Large Manufacturers |

10,000+/month |

Automatic PVC welding machine |

PVC-coated, vinyl |

Dual welding heads, conveyor system |

|

Home Improvement Retailers |

5,000-10,000/month |

Automatic roller blinds fabric welding machine |

Polyester blends, vinyl |

Bar code tracking, cloud reporting |

|

Custom Blind Shops |

500-5,000/month |

Semi-automatic zip blinds welding machine |

Coated fabrics, sunscreens |

Pattern memory, quick-change templates |

|

Interior Design Firms |

50-500/month |

Manual roller shade welding machine |

Decorative fabrics, linens |

Portable design, adjustable temperature |

|

Specialty Contractors |

Varies project-based |

Portable fabric welding machine |

Outdoor fabrics, mesh |

Battery operation, compact design |

Welding vs. Sewing: Critical Comparison

|

Feature |

Fabric Welding Machine |

Traditional Sewing |

Advantage |

|

Seam Strength |

35-50% stronger bond |

Thread-dependent |

Welding |

|

Water Resistance |

Completely waterproof |

Leaks at stitch holes |

Welding |

|

UV Resistance |

No degradation |

Threads fade/fray |

Welding |

|

Production Speed |

2-3x faster |

Limited by stitching |

Welding |

|

Material Waste |

8-12% less |

Higher pattern waste |

Welding |

|

Aesthetic Finish |

Seamless appearance |

Visible stitching |

Welding |

|

Operating Cost |

$1.10-1.80/hr |

$0.80-1.50/hr |

Sewing |

|

Startup Cost |

$1,500-$80,000 |

$300-$5,000 |

Sewing |

|

Customization |

Limited patterns |

Unlimited designs |

Sewing |

Key Features of Modern Welding Systems

Advanced Power Management:

- Energy recovery systems reduce consumption by 30-40%

- Automatic sleep mode after 15 minutes of inactivity

- Solar-compatible models available

Noise Reduction Technology:

- Sound-dampened cabinets (65dB vs. 85dB in older models)

- Vibration-absorbing mounts

- After-hours operation capability

Production Optimization:

- Laser-guided material alignment

- Auto-calibration sensors

- Real-time weld quality monitoring

Safety Innovations:

- Thermal overload protection

- Emergency brake systems (0.2s response)

- Fume extraction ports

Material Compatibility Guide

|

Material |

Welding Method |

Temperature |

Special Notes |

|

PVC-Coated Polyester |

Hot Air |

380-420°C |

Most common blind material |

|

100% Vinyl |

High Frequency |

160-180°C |

Requires Teflon-coated plates |

|

Blackout Fabrics |

Ultrasonic |

170-190°C |

Layer limit: 3 materials |

|

Solar Screen Mesh |

Hot Wedge |

340-370°C |

Use backing tape for strength |

|

Decorative Woven |

Impulse |

220-250°C |

Test for discoloration first |

Step-by-Step Selection Process

1. Production Assessment

- Calculate daily output requirements

- Determine shift patterns

- Project 3-year growth

2. Material Testing

- Obtain fabric swatches

- Conduct weld strength tests

- Check colorfastness at temperature

3. Space Planning

- Machine footprint + 360° access

- Material handling zones

- Ventilation requirements

4. Budget Analysis

- Consider ROI timeline (typically 12-18 months)

- Factor in training costs

- Include maintenance contracts

5. Vendor Evaluation

- Check service network coverage

- Review spare parts availability

- Request client references

Industry-Specific Implementation

Custom Blind Shops:

- Opt for semi-automatic zip blinds welding machines with pattern memory

- Maintain fabric library for quick material recall

- Implement modular production stations

Home Improvement Retailers:

- Install automated roller shade welding machines with ERP integration

- Use predictive maintenance software

- Implement barcode tracking from production to installation

Interior Designers:

- Choose portable fabric welding machines under 50kg

- Maintain swatch library with weld settings

- Offer client demonstrations as value-add

Maintenance Best Practices

Daily:

- Brush weld residue from heating elements

- Check air filtration systems

- Calibrate temperature sensors

Weekly:

- Inspect wiring for wear

- Test emergency stop functions

- Lubricate moving parts

Quarterly:

- Replace Teflon coating on plates

- Upgrade control software

- Professionally calibrate instruments

Cost-Saving Strategies

1. Energy Recovery: Capture waste heat for facility warming

2. Material Nesting: Software to optimize fabric usage

3. Preventive Maintenance: Reduce downtime by 60-80%

4. Modular Upgrades: Add automation features incrementally

5. Off-Peak Production: Utilize lower electricity rates

Future Industry Trends

1. AI-Powered Quality Control: Real-time defect detection

2. IoT Integration: Machine-to-machine coordination

3. Sustainable Materials: Biodegradable welding tapes

4. Hybrid Welding-Sewing: Combined process units

5. Cloud-Based Management: Remote production monitoring

---

Frequently Asked Questions

Q: How long does it take to train welding machine operators?

A: Basic operation requires 1-3 days, while advanced programming takes 2-4 weeks. Manufacturers typically offer certification programs.

Q: Can welded blinds be repaired?

A: Yes, using portable spot welders. Repairs maintain 85-95% of original strength when done properly.

Q: Are there eco-friendly welding options?

A: New solar-powered models reduce carbon footprint by 40%. Water-based cooling systems also minimize environmental impact.

Q: What safety certifications should I look for?

A: Ensure machines meet CE, UL, or ISO 13849 standards with proper OSHA compliance documentation.

Q: How long do welding machines typically last?

A: With proper maintenance, industrial units operate 10-15 years. Critical components like heating elements last 2-5 years.

---

Why Choose Welding Over Sewing?

Modern fabric welding solutions provide superior durability and efficiency for roller blind production. While sewing machines maintain relevance for intricate designs, PVC welding machines deliver:

- 3x faster production speeds

- 100% waterproof seams

- 50% reduction in material waste

- Consistent professional finish

The roller shade welding machine has become the industry standard for manufacturers prioritizing quality and efficiency. For businesses entering the market, semi-automatic zip blinds welding machines offer the ideal balance between flexibility and productivity.