Introduction to Ultrasonic Fabric Cutting Technology

Fabric cutting sits at the heart of the textiles and manufacturing industries, shaping the precision, efficiency, and quality of final products. While traditional cutting methods (mechanical blades, hot knives, or laser cutters) still find use, the advance of ultrasonic cutting technology has revolutionized modern manufacturing processes across the globe.

Ultrasonic fabric cutters harness the power of high-frequency ultrasonic vibrations to slice through fabrics and comparable materials with exceptional precision and minimal fraying. From delicately cutting silk and lace to processing rugged synthetics and composites, ultrasonic fabric cutters deliver unmatched performance in multiple industries.

---

Types of Ultrasonic Fabric Cutters

Ultrasonic fabric cutting solutions come in several forms, catering to different volumes, materials, and patterns. Knowing the differences helps you select the perfect ultrasonic cutting machine or ultrasonic cutting table for your specific context.

1. Handheld Ultrasonic Cutters

Handheld ultrasonic fabric cutters feature ergonomic designs for operator comfort and ease. Lightweight and highly maneuverable, these cutters excel at detailed and intricate cutting work. Their applications include:

- Cutting curves, corners, and custom patterns

- Sampling and prototype development

- Small-batch garment creation

- On-site adjustments in workshops or tailor shops

Handheld cutters usually feature interchangeable ultrasonic cutting blades. For highly delicate materials like silk or chiffon, a thin blade ensures a slice without heating or burning the fibers. For thicker synthetics or leather, heavier-duty blades are available.

Recommended for:

- Garment manufacturing

- Roller blind cutting

- Leather goods

- Tailoring, prototyping, crafts

---

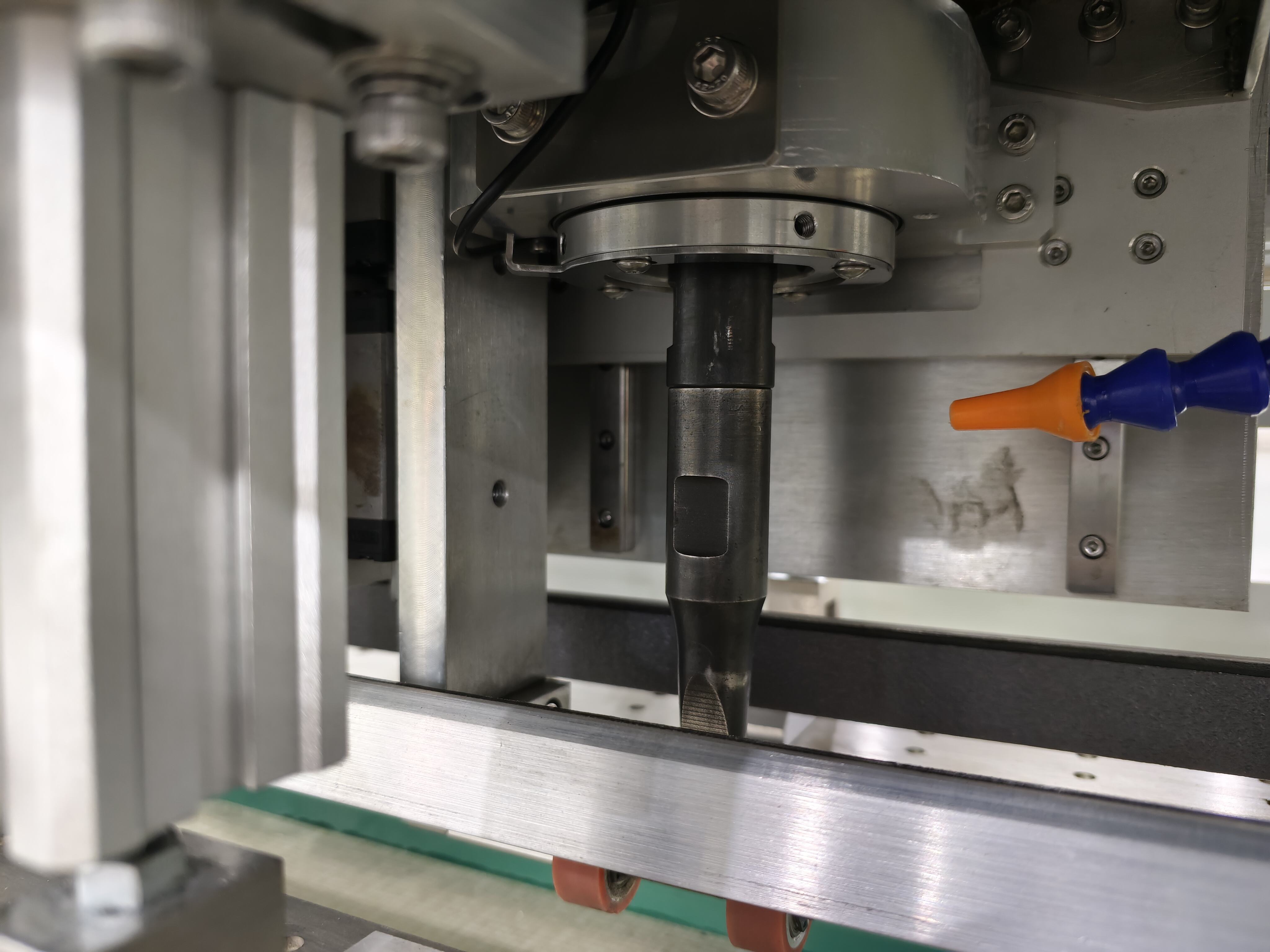

2. Ultrasonic Oscillating Cutters

Ultrasonic oscillating cutters integrate high-speed oscillating blades excited by ultrasonic energy, sometimes augmented by air-jet curtains for enhanced precision and debris removal. These machines can effectively:

- Slice through multiple layers simultaneously

- Handle complex or contoured shapes

- Integrate seamlessly into automated production lines

Their oscillation ensures minimal pressure on the fabric, making them perfect for mass production where precision with speed is key.

Recommended for:

- Textile and apparel plants

- Automotive interiors (e.g., seat covers, headliners)

- Composite material manufacturing

Blade options:

Choose flat, rounded, or pointed blades depending on edge requirements; serrated for technical textiles.

---

3. Ultrasonic Slitting Cutters

Ultrasonic slitting cutters (or slitters) are stationary or fixed-blade machines designed primarily for continuous slitting of roll materials. The blades vibrate at ultrasonic frequencies to produce:

- ESD-free, frayless, sealed edges

- Minimal dust and particulate release

- Surgical precision for straight, repeatable cuts

Widely adopted in modern nonwoven, roller blinds,film, laminate, and synthetic substrate processing, these machines are instrumental in the packaging, automobile, and hygiene supply sectors.

Recommended for:

- Nonwovens (e.g., medical gowns, face masks)

- Plastic films and laminates

- Automotive insulation and soundproofing

- Packaging materials

- roller blinds

Blade type:

Wide, robust slitting blades engineered for edge sealing.

---

4. Tabletop Ultrasonic Cutters

A tabletop ultrasonic fabric cutter is a stationary cutting system featuring a built-in ultrasonic cutting table. The table keeps materials taut and perfectly aligned for programmable, repeatable, and highly precise cuts.

- Supports batch production and sample making

- Ideal for small to medium manufacturing runs

- Accommodates various blade types for different materials

- Often includes digital or CNC control for complex patterns

Recommended for:

- Fashion houses and small apparel factories

- Prototyping labs

- Technical textile processors

Blade recommendations:

Select straight, squared, or pattern-cuttable blades; mix for customizable edge qualities.

---

Specifications and Features of Ultrasonic Fabric Cutters

Before selecting an ultrasonic cutting machine, understanding their core specifications ensures you match the tool to your demands.

Ultrasonic Power

- Measured in watts (W), usually from 60W to 500W for fabric cutting

- High power = greater cutting capacity, necessary for thick or multilayer materials

- Key for matching machine to application (e.g., lightweight vs. heavy technical textiles)

Frequency Range

- Typical operating frequencies: 20 kHz to 40 kHz

- Lower frequencies (20 kHz): Greater cutting force for thicker/harder materials

- Higher frequencies (30-40 kHz): Finer, more delicate cuts for soft or intricate materials

Ultrasonic Cutting Blade Length

- Blade lengths typically range from 20mm to 100mm

- Shorter blades: Greater maneuverability; precision detailing

- Longer blades: Improved straight-line and multi-layer capability

Power Control & Digital Interfaces

- Most modern ultrasonic cutting machines provide adjustable power control via digital interfaces, allowing fine-tuning for material hardness, thickness, or desired cut quality.

Integrated Features

- Automatic feeding systems

- Vacuum tables for holding fabric steady

- Dust and debris extraction systems

- Programmable pattern controls (CNC/PLC interfaces)

- Interchangeable blade systems for roasting, slitting, or contour cutting

---

Maintenance Best Practices for Ultrasonic Fabric Cutters

Proper care and maintenance ensure optimal machine longevity and consistent production quality:

Routine Cleaning

- After every use, clean blades and machine surfaces using a soft brush or lint-free cloth.

- For residue build-up, apply mild detergents or solvents recommended by the manufacturer. Avoid harsh abrasives or unauthorized chemicals.

Blade Lubrication

- If prescribed, lubricate moving parts as per manufacturer guidelines.

- Use only approved lubricants to avoid contamination or equipment damage.

Inspection

- Check blades for nicks, dullness, or warping. Replace dull blades promptly.

- Inspect wiring, connectors, and ultrasonic generator units for signs of overheating or fraying.

Storage

- Store the device in a dry, dust-free environment, preferably in a protective case.

- If possible, keep blades vertical to maintain the cutting edge integrity.

Scheduled Servicing

- Adhere to recommended service intervals, especially in high-production environments.

- Keep records for maintenance and parts replacement to boost equipment longevity.

---

Key Benefits of Ultrasonic Cutting Machines for Fabric

Clean, Sealed Edges

- The ultrasonic vibration both cuts and thermally seals synthetic fibers, preventing fraying or unraveling.

- Reduces need for secondary processing (no hemming/burning required).

High Precision and Efficiency

- Fine control allows for intricate patterns, small radius corners, and consistently repeatable shapes.

- Reduced waste; increased yield per material roll.

Low Operator Skill Requirement

- Most ultrasonic cutting systems are intuitive to use, minimizing operator error and training time.

Minimal Dust, Debris, and Contamination

- Unlike mechanical or laser cutting, ultrasonic systems produce less particulate, making them cleaner for sensitive industries (electronics, medical).

Versatility Across Materials

- Suitable for textiles, technical fabrics, synthetics, thin metals, films, composites, plastics, and even rubber.

Energy and Cost Efficiency

- Lower input power compared to lasers or heated knives.

- Less blade wear due to non-contact cutting, minimizing consumables cost.

---

Ultrasonic Fabric Cutting in Industry: Application Scenarios

Ultrasonic cutting machines are an integral part of diverse industries, driving innovation, safety, and enhanced productivity. Here are key sectors and how they uniquely benefit from ultrasonic cutting technology, with blade recommendations for each:

1. Textiles and Apparel

- Use Cases: Cutting natural and synthetic fabrics, lace, mesh, satins, spandex, and technical textiles.

- Benefits: No fraying, precision for intricate garment designs, and suitability for delicate, high-value textiles.

- Recommended Blade: Thin, sharp blade for silks and synthetics; serrated for knitwear.

2. Leather Goods

- Use Cases: Cutting genuine and synthetic leathers, suede, and heavy upholstery.

- Benefits: Clean, sealed edge; avoids scorched surfaces common with hot knives; minimizes tool pressure on luxury materials.

- Recommended Blade: Heavy-duty, robust blade designed for dense materials.

3. Automotive Interiors

- Use Cases: Fabrication of soundproofing mats, carpets, seat covers, headliners, insulation.

- Benefits: Seamless integration into assembly lines, consistent multi-layer cuts, edge sealing improves part durability.

- Recommended Blade: Robust oscillating blade for composites; wide slitting blade for carpets.

4. Packaging and Nonwovens

- Use Cases: Slitting and shaping nonwovens, films, foils, sustainable or recyclable packaging.

- Benefits: Dust-free, sealed cutting; enables production for medical, food, and hygiene packaging.

- Recommended Blade: Wide, continuous slitting blade.

5. Medical Equipment and Supplies

- Use Cases: Manufacturing of surgical masks, gowns, bandages, nonwoven medical disposables.

- Benefits: Sterile, sealed edges; reduced contamination; precision for custom-fitted wearables.

- Recommended Blade: Thin sealing blade for nonwoven and medical textiles.

6. Food Processing (Ultrasonic Food Cutting)

- Use Cases: Portioning bakery goods, cheese, confections with sticky, delicate textures.

- Benefits: Clean slices without product compression or residue sticking; easy-to-clean blades.

- Recommended Blade: Wide, Teflon-coated blade for non-stick food contact.

7. Electronics and Composites

- Use Cases: Cutting insulation, carbon fiber, fiberglass, circuit substrates.

- Benefits: Non-contaminating, dust-free; allows complex patterns; minimal static generation.

- Recommended Blade: Abrasion-resistant blade with sealed edge function.

8. Construction and Engineering

- Use Cases: Trimming geotextiles, insulation, waterproof membranes.

- Benefits: High-speed, long-straight cuts; edge sealing resists weather and moisture intrusion.

- Recommended Blade: Heavy-duty extended blade for thick technical textiles.

9. Handicrafts, DIY, & Small Workshop Use

- Use Cases: Custom craft cutting, hobbyist production, bespoke tailoring.

- Benefits: Flexible, portable, and user-friendly for small-batch or creative uses.

- Recommended Blade: Interchangeable set (flat for general, pointed for detail work).

---

Choosing the Right Ultrasonic Fabric Cutter: A Structured Guide

With a wide range of ultrasonic cutting machines and systems available, careful consideration ensures the investment maximizes returns for your unique production environment.

1. Define the Application Scope

- Are you cutting single layers, multilayer composites, rolls, or individual patterns?

- Choose a handheld, oscillating, slitting, or tabletop system accordingly.

2. Material Compatibility

- Ensure the machine (and accessory blade types) matches your target materials—be it silks, synthetics, leathers, technical textiles, or food products.

- Assess the fabric’s thickness, weave, and texture.

3. Cutting Technique Comparative

- Ultrasonic cutting: Super-clean, sealed edges, low dust, ideal for synthetics and modern composites.

- Mechanical blades: May suffice for thick, loosely woven, or natural fabrics.

- Laser cutting: Great for precision, but can cause burnt edges and requires fume extraction.

4. Production Volume and Speed

- Prototype/small batch: Handheld or tabletop ultrasonic cutters are ideal.

- Mass/high-speed production: Integrated oscillating or slitting cutters with auto-feed.

- Match machine cycling speed and power rating to your output goals.

5. Key Machine Features

- CNC/digital controls for accuracy and automation.

- Quick-change blade systems to increase flexibility.

- Dust extraction/vacuum tables for clean workstations.

6. Containment and Safety

- Prioritize models with robust dust/debris control, especially for medical, food, or electronics applications.

7. Budget Considerations

- Calculate upfront investment, operational costs, consumables (blades), and maintenance.

- Weigh costs against expected throughput, waste reduction, and labor savings.

---

Frequently Asked Questions (Ultrasonic Fabric Cutter Q&A)

Q: What is the main advantage of ultrasonic cutting over traditional methods?

A: Ultrasonic cutting produces clean, sealed edges without fraying or burning, increases precision, and reduces fabric waste.

Q: Are ultrasonic cutters suitable for all fabrics?

A: Ultrasonic cutters work best on synthetic, blended, or technical textiles. Some heavy, densely woven, or purely natural fibers (e.g., thick cotton denim or wool) may yield better results with mechanical cutting.

Q: Can ultrasonic cutting machines process multiple types of materials?

A: Yes. They cut textiles, nonwovens, leather, films, plastics, food products, composites, and more—with the proper blade and frequency.

Q: How durable are ultrasonic cutting machine blades?

A: Ultrasonic blades generally last longer than mechanical blades as there is less friction and wear. Blade lifespan depends on material toughness and maintenance practices.

Q: What makes ultrasonic cutting machines ideal for the electronics and medical industries?

A: Low particulate production, sealed edges for cleanroom compatibility, and capability to cut sensitive materials without heat damage or contamination.

---

Conclusion

The evolution of ultrasonic cutting tables and ultrasonic cutting machines has brought unprecedented accuracy, safety, and productivity to fabric and material processing industries. Whether you manufacture technical textiles, mass-produce automotive interiors, craft garments, or cut highly sensitive medical or food products, the precision and versatility of ultrasonic cutting solutions are unparalleled.

By understanding ultrasonic fabric cutter types, matching them to your industry, selecting the right specifications, and implementing best practices in maintenance and operation, your business can achieve superior results with lower costs and higher quality.

Invest in a cutting-edge ultrasonic fabric cutter to power your manufacturing innovation and efficiency today.

---

Summary Table: Industry Applications and Recommended Cutter Types

|

Industry |

Recommended Ultrasonic Cutter |

Suggested Blade Type |

|

Textiles & Apparel |

Handheld, Tabletop |

Thin/serrated |

|

Leather Goods |

Handheld, Oscillating |

Robust/heavy-duty |

|

Automotive |

Oscillating, Slitting |

Wide/oscillating |

|

Roller Blinds/Nonwovens |

Slitting |

Wide slitting |

|

Medical Supplies |

Slitting, Tabletop |

Thin sealing |

|

Food Processing |

Tabletop, Food-safe models |

Wide, coated |

|

Electronics/Composites |

Oscillating, Tabletop |

Abrasion-resistant |

|

Construction |

Slitting, Oscillating |

Extended heavy-duty |

|

Handicrafts/DIY |

Handheld |

Interchangeable |

---

For further technical guidance or to request a quotation for an ultrasonic cutting machine or ultrasonic cutting table for your facility, contact us today!