The global demand for window coverings continues to grow, driven by urbanization, rising disposable incomes, and an increasing focus on energy efficiency and privacy. Within this market, roller blinds stand out for their clean aesthetics, functional simplicity, and versatility. They are a staple in homes, offices, and commercial spaces worldwide. For manufacturers, this presents a significant opportunity. However, establishing a profitable and efficient roller blind production line requires a deep understanding of the specialized machinery involved and the critical considerations that underpin success.

This in-depth guide, brought to you by Dongguan Ridong Intelligent Equipment Co., Ltd., a pioneer in window covering machinery since 2007, provides a comprehensive overview of the roller blind manufacturing process. We will explore the essential machines required at each stage, from raw material to finished product, and delve into the vital operational and strategic factors that separate thriving manufacturers from the rest.

The Anatomy of a Roller Blind and Its Manufacturing Workflow

Before diving into the machinery, it's crucial to understand the core components of a standard roller blind:

1. Fabric: The main shade material, which can vary from simple sun-filter to total blackout or even moisture-resistant PVC.

2. Roller Tube: Typically a lightweight aluminum or steel tube onto which the fabric is rolled.

3. Bottom Rail: A weighted bar that provides tension, ensures the blind hangs straight, and allows for easy operation.

4. Control Mechanism: This can be a spring-loaded roller system (for chain-operated blinds) or a component of a motorized system.

5. End Caps and Brackets: Plastic or metal fittings that secure the blind into the window frame.

The manufacturing workflow follows a logical sequence to assemble these components:

Tube & Rail Production -> Fabric Processing -> Component Assembly -> Quality Control & Packaging.

Part 1: The Essential Machinery for Roller Blind Production

A modern roller blind factory relies on a suite of specialized machines designed for precision, speed, and repeatability.

1. Roller Tube Production and Processing Machines

The roller tube is the structural backbone of the blind. Its precise fabrication is non-negotiable.

Automatic Tube Cutting Machines: These are the starting point for tube processing. A high-quality automatic tube cutter can handle aluminum or steel coils, straightening them and cutting them to exact, pre-set lengths. Key features to look for include:

CNC Control: For precise length setting and batch counting.

Automatic Feeding: Minimizes manual labor and increases throughput.

Burr-Free Cutting: A clean cut is essential to prevent damage to the fabric and ensure smooth operation. Advanced machines use rotary cutting tools to achieve this.

Consideration: The machine must be adjustable to handle the various diameters of tubes required for different blind sizes and weights.

Tube Notching and Punching Machines: Once cut to length, the tubes require notches, holes, or specific profiles to accommodate the control mechanism and end caps.

Manual Notching Machines: Suitable for low-volume or custom shops, where an operator places the tube and activates the punching mechanism.

Automatic Tube Notching Machines: For high-volume production, these machines automatically feed the tube and perform multiple notching and punching operations in one cycle. This ensures every tube is identical, which is critical for the consistent function of the final product.

Ridong's Expertise: With years of experience, Ridong has developed tube processing lines that integrate cutting and notching, ensuring a seamless, high-volume workflow with minimal tolerance for error.

2. Bottom Rail Manufacturing Machines

The bottom rail must be straight, sturdy, and correctly profiled to hold the fabric securely.

Bottom Rail Roll Forming Machines: This is the core technology for creating the bottom rail. These machines take a strip of aluminum or steel (a "coil") and progressively shape it through a series of rollers until it forms the desired complex profile.

Advantages: Roll forming is a continuous, high-speed process that produces a consistent, strong profile with very little material waste compared to extrusion.

Customization: The forming rolls can be designed to create a wide variety of profiles tailored to different blind systems and fabric attachment methods (e.g., screw-on, snap-on, or slide-in channels).

Automatic Bottom Rail Cutting Machines: Similar to tube cutters, these machines take the continuously formed rail and cut it to the exact required lengths. Precision here is vital to ensure the rail matches the width of the fabric and tube perfectly.

3. Fabric Processing and Welding Machines

How the fabric is cut and attached to the components is a major differentiator in quality and efficiency.

Fabric Slitting and Rewinding Machines: Fabric is often purchased in wide rolls. A slitting machine unwinds the master roll, uses circular knives to slit it into narrower widths required for specific blind sizes, and then rewinds the slit fabric onto individual cores. This is a more efficient method than purchasing pre-slit fabric.

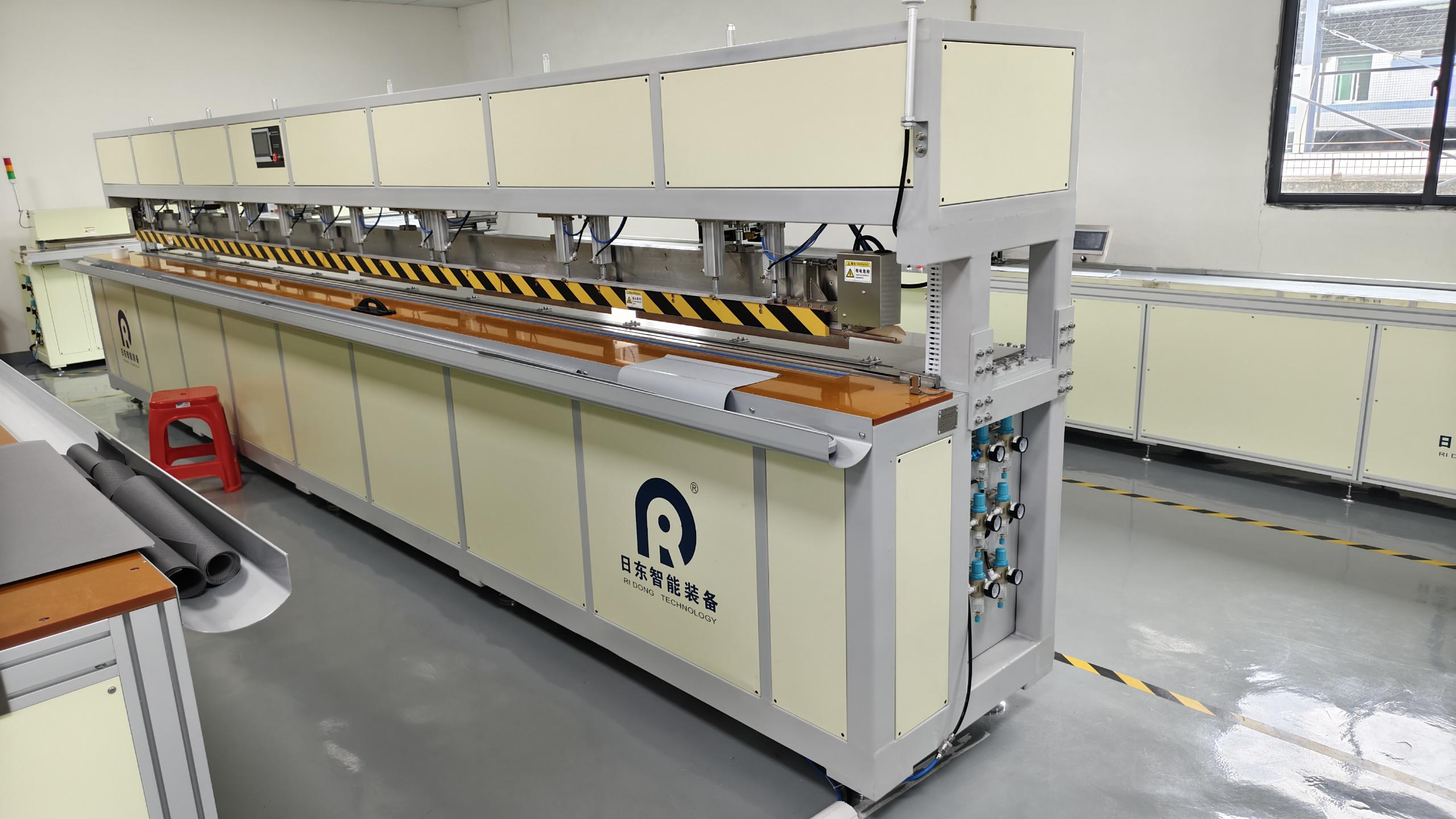

Fabric Welding Machines for Roller Blinds: This is a superior alternative to traditional sewing or stapling for attaching fabric to the roller tube and bottom rail.

Hot-Air/Wedge Welding: These machines use a focused stream of hot air to melt a specialized welding tape (often PVC-based) placed between the fabric and the component (tube or rail). Under pressure, the materials fuse into a single, incredibly strong bond.

Advantages of Welding:

Exceptional Strength: The weld is often stronger than the fabric itself, eliminating the risk of the fabric detaching from the tube—a common failure point in cheaply made blinds.

Clean, Professional Finish: No unsightly staples or stitch lines. The bond is flat and seamless.

Waterproof & Airtight: The sealed seam prevents moisture and air penetration, which is crucial for outdoor or moisture-prone applications.

High Speed: Automated welding heads can complete a seam in seconds.

Ridong's Leadership: Ridong is at the forefront of fabric welding technology, offering machines specifically calibrated for the diverse materials used in roller blind production, from standard polyesters to heavy-duty blackout and PVC fabrics.

4. Assembly and Testing Equipment

The final stage brings all components together.

Semi-Automatic and Fully Automatic Assembly Stations: These are custom-configured workstations that guide operators through the assembly process. They may include fixtures for holding the tube, automatic dispensers for end caps and springs, and pneumatic tools for securing components. For high-volume production, fully automatic lines can insert the spring mechanism, attach end caps, and wind the fabric onto the tube with minimal human intervention.

Spring Coiling and Insertion Machines: For spring-operated blinds, these machines pre-tension and insert the internal spring mechanism into the roller tube. Correct spring tension is critical for smooth and safe operation.

Function Testing Rigs: A simple but essential station where every finished blind is unrolled and rolled back up several times to check for smooth operation, correct alignment, and the integrity of all components.

Part 2: Critical Considerations for a Successful Roller Blind Business

Investing in the right machinery is only the first step. Long-term success depends on strategic and operational excellence.

1. Defining Your Market and Product Strategy

Your choice of equipment will be dictated by your target customers.

Standard Residential Blinds: Focus on versatile machines that can handle common fabric types and a range of standard sizes efficiently.

Commercial/Contract Blinds: You may need heavier-duty tube processing and more robust welding machines to handle larger blinds and higher volumes.

Motorized & Smart Blinds: This requires additional assembly stations and technical expertise for integrating motors and control systems. Planning for this expansion from the start is wise.

Custom, High-End Products: While requiring more manual intervention, this niche may demand specialized fabric handling and finishing capabilities.

2. The Critical Role of Raw Materials

The quality of your raw materials is as important as the quality of your machines.

Tubes: The gauge (thickness) and alloy of aluminum tubes must be suited to the blind's size and weight. A tube that is too weak will bow, causing operational failure.

Fabrics: Different fabrics behave differently during welding and cutting. The temperature, speed, and pressure of your welding machine must be precisely calibrated for each material type (e.g., blackout fabric, sunscreen mesh, PVC). Always conduct material tests.

Components: Source end caps, brackets, and control mechanisms from reliable suppliers. Inconsistent component quality can lead to assembly line stoppages and product failures.

3. Workflow Optimization and Factory Layout

An inefficient layout creates bottlenecks and hidden costs. Organize your factory in a linear flow:

Raw Material Storage -> Tube/Rail Production -> Fabric Slitting -> Assembly Line (Tube + Fabric + Rail) -> Testing -> Packaging.

Ensure there is a logical, short-distance flow of materials between stations. Use lean manufacturing principles to minimize work-in-progress inventory and handling.

4. Quality Control: A Non-Negotiable Practice

Implement a multi-stage QC process:

Incoming QC: Check raw materials upon arrival.

In-Process QC: Operators should check components at each stage (e.g., tube length, weld strength).

Final QC: Every single blind should be functionally tested before packaging.

Building a reputation for reliability, a core part of Ridong's "reliable quality" value, is your greatest asset.

5. The Human Element: Training and Safety

Even highly automated lines need skilled operators and technicians. Invest in training for:

Machine Operation & Programming: Understanding how to set up jobs and perform basic adjustments.

Preventative Maintenance: Daily and weekly cleaning, oiling, and inspection to prevent unexpected downtime.

Safety Protocols: All machinery must be operated with proper guards and safety procedures in place.

6. After-Sales Support and Service

Your relationship with your machinery supplier is a long-term partnership. The "customer first" principle means prioritizing suppliers who offer:

Comprehensive Installation and Training.

Readily Available Spare Parts.

Responsive Technical Support for troubleshooting.

A machine that is down is a direct loss of revenue. A reliable partner like Ridong ensures your production line remains productive.

Conclusion: Building a Foundation for Growth with Intelligent Equipment

The journey to becoming a leading roller blind manufacturer is built on a foundation of robust technology and sound operational practices. By understanding the intricate roles of tube cutters, roll formers, and fabric welders, and by embracing the critical considerations of material science, workflow, and quality control, businesses can position themselves for sustainable growth in a competitive market.

The mission of Dongguan Ridong Intelligent Equipment Co., Ltd. is to be more than just a machinery vendor. With 18 years of dedicated experience and a unwavering commitment to "honest management, reliable quality, customer first," we provide the integrated solutions, technical expertise, and reliable partnership that empower our clients to transform raw materials into high-value products, efficiently and profitably. In the precise world of roller blind manufacturing, the right machinery partner is not just an advantage—it is a necessity.

---

About Dongguan Ridong Intelligent Equipment Co., Ltd.:

Established in 2007, Dongguan Ridong Intelligent Equipment Co., Ltd. is a leading enterprise specializing in the R&D, sales, and service of advanced machinery for the production of roller blinds, curtains, outdoor sunshades, and windproof screens. With a core philosophy of "honest management, reliable quality, customer first," Ridong has earned the high trust of a global clientele by providing affordable, high-performance, and reliable automation solutions that drive productivity and innovation in the window coverings industry.