How Fabric Welding Equipment Works: Principles and Core Components

What is a fabric welding machine and how does it work?

Fabric welding gear works by applying controlled heat, pressure, or ultrasonic waves to join thermoplastics like PVC and polyethylene together. When these materials get heated up at the point where they meet, the polymers actually fuse on a molecular level without needing glue or sewing. Most hot air welders operate around 300 to 600 degrees Fahrenheit, which is pretty intense but necessary for proper bonding. High frequency welding takes another approach using dielectric heating that allows manufacturers to seal things quickly and accurately. A recent report from the Industrial Fabrication Journal mentioned that newer welding machines can keep temperatures within half a percent accuracy, so seams stay strong and consistent throughout entire production batches. This kind of precision matters a lot when making products that need to hold up under stress or exposure to harsh conditions.

Core components of fabric welding machines

Key components include:

- Heating elements: Deliver regulated thermal energy—ceramic heaters in hot air systems, metal wedges in conduction-based setups

- Pressure rollers: Apply 10—50 PSI to consolidate melted layers and ensure complete bonding

- Digital controllers: Monitor and adjust temperature, feed speed, and dwell time for consistent results

- Cooling zones: Rapidly solidify seams post-weld to prevent deformation

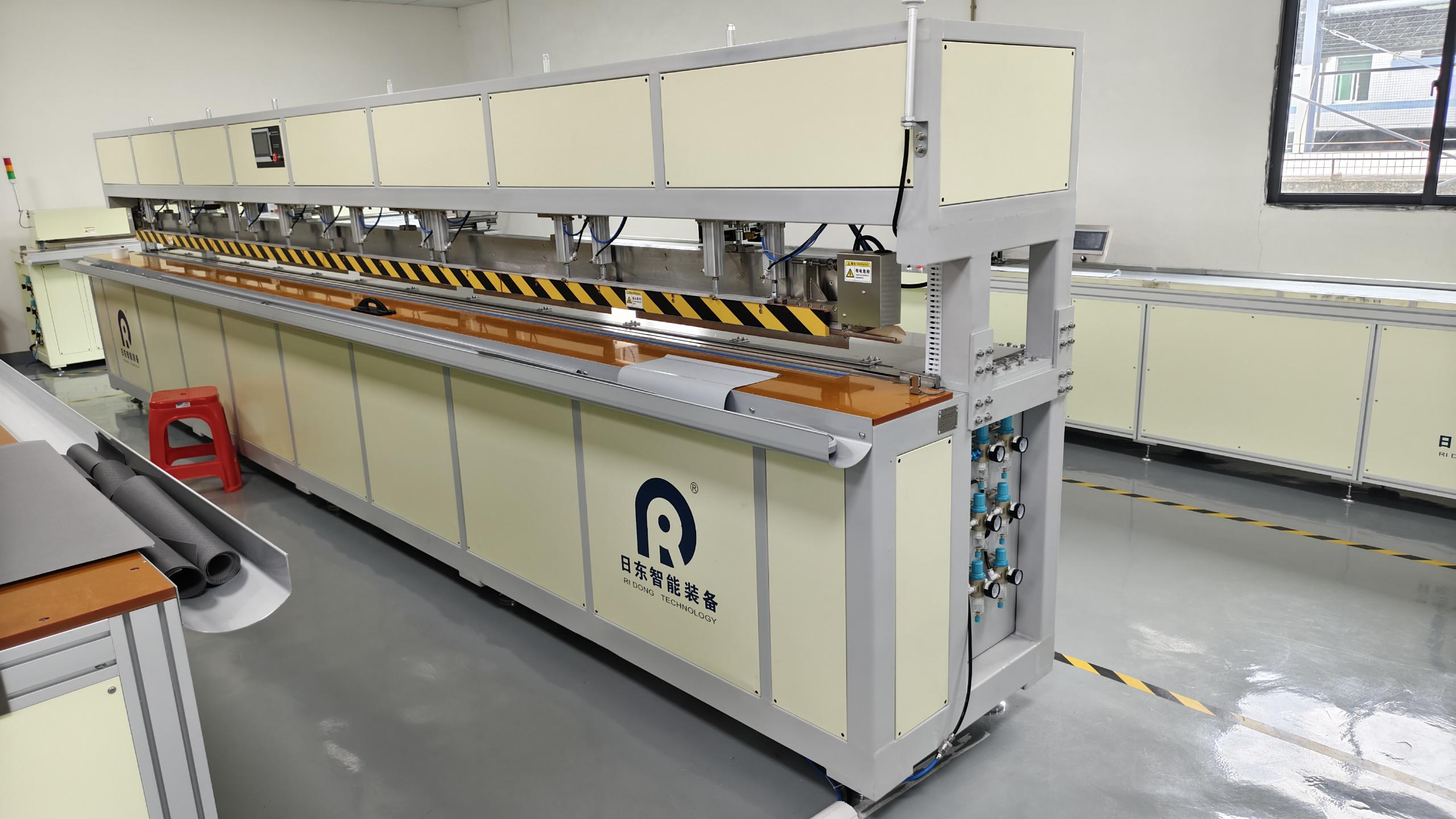

Industrial-grade machines often integrate servo motors and PLCs for automated seam tracking, essential for producing tarpaulins, inflatable structures, and medical textiles with high repeatability.

Key characteristics and industrial applications of welding equipment

Fabric welding systems that perform at high levels come with adjustable power settings ranging from 1 to 20 kW, plus programming options that match different materials and their thicknesses. The medical field really relies on RF welding technology these days because it creates those super tight, sterile seals needed for IV bags, meeting industry standards with around 99.9% seal integrity according to Medical Device Standards from 2022. When we look at construction applications, hot wedge welders are joining PE geomembranes at impressive speeds of about 1,200 linear feet each hour. These welds have peel strength measurements exceeding 50 Newtons per centimeter. That's actually 2 to 4 times stronger than regular sewn seams when it comes to resisting wear and tear during installation and operation.

Types of Fabric Welding Technologies: Hot Air, Hot Wedge, and RF Welding

Hot Air Welding: Principles and Operational Efficiency

Hot air welding works by blowing really hot air, around 300 to 500 degrees Celsius, onto plastic fabrics until they start to melt. Then we press the pieces together while still warm so they fuse properly. The process can handle all sorts of materials including polyester, nylon, and even vinyl without needing much adjustment between jobs. That makes it great when dealing with those tricky curved seams or fabrics that vary in thickness throughout. According to some industry folks who looked into fabric welding tech last year, many manufacturers actually prefer this technique for things like outdoor awnings and inflatable structures because it adapts well to different requirements. Newer machines on the market today consume about 20% less electricity than older versions did, which cuts down costs significantly for shops doing moderate production runs rather than mass manufacturing.

Hot Wedge Welding: Precision and Consistency in Seam Formation

The process involves heating a metal wedge which runs between fabric layers, melting them before they get pressed together by roller systems. Because the heated element touches both materials directly, it spreads warmth evenly across the surface area, resulting in solid, uniform seams that hold up well over time. This works especially well with coated fabrics such as those reinforced with PVC commonly used in tarpaulins. Boat builders and transportation companies have adopted this technique for creating straight, watertight joins in things like truck side curtains and protective coverings for equipment. Some studies indicate that automated systems cut down on seam problems by around 34 percent when compared to old fashioned hand techniques, making a big difference in harsh working conditions where reliability matters most.

Radio Frequency (RF) Welding: High-Speed Bonding for Thermoplastics

RF welding works by exciting polymer molecules through electromagnetic waves, creating internal heat that fuses materials together in roughly 2 to 5 seconds per seam. This method is particularly well suited for working with TPU films and various PVC medical items, producing clean seals that don't leave charred surfaces behind. What makes RF welding stand out is its ability to handle intricate three dimensional shapes, which explains why manufacturers rely on it so much for things like aircraft parts, protective gear straps, and specialized inflatable structures. The controlled heating process prevents damage to delicate underlying materials that would otherwise be ruined by conventional methods.

Comparative Analysis: When to Use Hot Air, Hot Wedge, or RF Welding

| Criteria | Hot Air | Hot Wedge | RF Welding |

|---|---|---|---|

| Best For | Curved seams, mixed materials | Straight seams, thick coatings | Thermoplastics, intricate designs |

| Speed | Moderate (3—8 m/min) | Fast (5—10 m/min) | Very fast (10—15 m/min) |

| Energy Use | Medium | High | Low |

| Typical Use Case | Inflatable boats, tents | Truck tarps, conveyor belts | Medical devices, PPE |

Hot air offers flexibility for prototyping and small batches; hot wedge delivers superior consistency for long linear seams; RF excels in high-speed, high-precision applications but requires strict material compatibility. Selection depends on production volume, seam geometry, and polymer properties.

Material Compatibility in Fabric Welding: PVC, PE, Vinyl, TPU, and Canvas

Weldability of PVC and Vinyl: Industry Standards and Limitations

PVC and vinyl show up everywhere from outdoor banners to weatherproof tarps and inflatable structures because they can be shaped easily and stand up to sun damage pretty well. The ISO 1167-2 standard actually recommends a minimum weld strength of around 12 Newtons per square millimeter when these materials are used for structural purposes. But there's a catch worth noting here. When the material gets thicker than about 3 millimeters, the welding just doesn't stick as well anymore. And if we're talking about vinyl specifically, it starts getting really fragile once temperatures drop below freezing point minus ten degrees Celsius. This makes cold cracks much more likely, which is why many professionals suggest warming up the material first before welding in those chilly conditions where seams need to hold together properly.

Polyethylene (PE) Challenges and Solutions in Welding Processes

Polyethylene has a relatively low melting point around 120 to 130 degrees Celsius which means it tends to burn through easily when welding. Experienced technicians know this well and typically adjust their equipment accordingly. Most often they'll lower the airflow to about half power or less on hot air systems, sometimes employing what's called a dual stage heating approach instead. When working with HDPE specifically, there's definitely a trade off worth noting. It takes roughly 30 to 40 percent more energy compared to regular LDPE materials. But here's the catch – those extra calories paid back in spades with welds that show about 20 percent greater tensile strength afterward. For applications where durability matters most like in agriculture or geosynthetic coverings, many professionals actually prefer HDPE despite the higher energy costs simply because the end product lasts longer under harsh conditions.

Thermoplastic Polyurethane (TPU) in High-Performance Applications

TPU is favored in medical and automotive fields for its elasticity (300—500% elongation) and chemical resistance. Welded at 160—180°C, it forms seamless joints in blood pressure cuffs, airbags, and protective gear. These bonds outperform adhesive alternatives in impact and fatigue resistance, crucial for safety-critical components.

Canvas and Hybrid Materials: When Adhesives Supplement Welding

Natural fiber content in canvas limits heat tolerance; optimal welding occurs between 140—160°C to avoid charring. Polyester-cotton blends often combine thermal bonding with epoxy adhesives, improving peel strength by 65% over welding alone. This hybrid approach enhances durability in rugged applications like military tents and protective enclosures.

| Material | Optimal Thickness | Temperature Range | Common Use Case |

|---|---|---|---|

| PVC | 0.5—3.0 mm | 180—220°C | Billboards |

| PE | 1.0—2.5 mm | 120—150°C | Agricultural Covers |

| TPU | 0.8—2.2 mm | 160—180°C | Medical Devices |

| Canvas | 1.5—4.0 mm | 140—160°C | Tents |

Industrial Applications of Fabric Welding Equipment

Fabric welding enables strong, seamless, and waterproof joints across sectors. By replacing traditional stitching with fused seams, it provides superior performance in durability, sealing, and environmental resistance.

Tarpaulins and Outdoor Covers: Durable Seams for Heavy-Duty Use

Welded PVC and PE tarps resist UV degradation, wind loads up to 75 mph, and temperatures from -40°F to 185°F. Construction and logistics industries depend on hot wedge welding for truck covers and industrial shelters, where seam failure could lead to water ingress and cargo damage.

Inflatable Structures: From Advertising Balloons to Emergency Shelters

RF welding produces airtight seams capable of maintaining 2—5 PSI internal pressure for over 5,000 cycles. These reliable bonds are vital in architectural membranes, emergency shelters, and life-support systems such as medical isolation units and fuel bladders, where leak-free performance is non-negotiable.

Medical Fabrics: Sterile, Seamless Welding for Safety-Critical Products

Medical-grade welding systems produce biocompatible TPU seams compliant with ISO 11607-1, achieving microbial ingress rates below 0.01 CFU/cm². Hot air and RF methods eliminate stitch holes that compromise sterility, making them essential for surgical drapes, sterile packaging, and personal protective equipment.

Billboards and Architectural Textiles: Long-Term Durability Under Stress

Vinyl billboards welded with dual-zone heating resist color fading and edge delamination for 8—12 years outdoors. Testing confirms that welded canvas retains 98% of base material strength after five years of cyclic loading—significantly outperforming sewn joints, which retain only 78%.

Selecting and Maintaining the Right Fabric Welding Equipment

Choosing Based on Material, Thickness, and Production Volume

Choosing the right equipment really comes down to what kind of material we're working with, how thick it is, and how much needs to be produced. TPU materials along with other polar polymers tend to work best when paired with RF welding systems because they respond well to dielectric properties. For heavy duty PVC applications, high pressure hot wedge welders are generally the way to go. When dealing with thinner materials under 2mm though, operators need to have good control over hot air settings so nothing gets burned during the process. Big manufacturers who run high volume operations typically spend the money on automated production lines capable of handling more than 100 meters every hour. Small workshops usually stick with semi automatic benchtop models since these cost less upfront and still get the job done for lower production volumes.

Automation, Space, and Portability Considerations

Benchtop hot air welders (under 25 kg) suit small workshops needing flexibility. Large-scale manufacturers deploy robotic arms integrated into conveyor systems for continuous operation. Portable units—some under 30 cm³—are standard for field repairs of inflatables, while fixed installations deliver micron-level seam accuracy in medical device production.

Industry-Specific Needs: Medical vs. Construction Sector Requirements

Medical welding requires ISO 13485-certified machines with HEPA filtration to maintain sterile conditions. In contrast, construction equipment prioritizes ruggedness and outdoor operability. A 2023 industry survey found 78% of shelter makers emphasize waterproof seam reliability, while 92% of medical device producers prioritize contamination-free welding environments.

Routine Maintenance for Hot Air, Hot Wedge, and RF Systems

- Hot air: Clean nozzles weekly to prevent clogging and airflow disruption

- Hot wedge: Replace Teflon-coated rollers every 500 hours to maintain release performance

- RF systems: Inspect dielectric blankets monthly for arcing or wear

Daily calibration reduces energy waste by up to 18% and extends component life across all system types.

Troubleshooting Common Issues and Extending Machine Lifespan

Brittle seams usually happen when the temperature isn't set right for whatever material is being worked with. When bonds aren't consistent across the board, that typically points to either pressure rollers showing signs of wear or pressure distribution problems somewhere in the system. For manufacturers looking to get more life out of their machines, predictive maintenance makes a big difference. Looking at actual usage data helps spot issues before they become major problems, which can actually add anywhere from three to five extra years onto equipment life. Machines with PLC controls offer something pretty handy too real time diagnostics via those blinking error codes. This means technicians can figure out what's wrong much quicker than before, so production lines don't stay down as long waiting for fixes.

FAQ

What are the different types of fabric welding technologies?

The primary types of fabric welding technologies include Hot Air Welding, Hot Wedge Welding, and RF (Radio Frequency) Welding. Each has unique benefits depending on the materials and applications involved.

How do I choose the right fabric welding machine for my needs?

Choosing the right machine involves considering the material and thickness you're working with, as well as the production volume. For instance, RF welding suits TPU materials well, while hot wedge welding is ideal for heavy-duty PVC applications.

Why is RF welding preferred for medical textiles?

RF welding is preferred for medical textiles because it creates sealed, sterile seams essential for products like IV bags, ensuring high seal integrity and compliance with medical standards.

What is the importance of maintaining fabric welding equipment?

Maintaining equipment is crucial for longevity and performance. Regular maintenance like cleaning nozzles and inspecting dielectric blankets ensures the machine's efficiency and prevents unexpected breakdowns.

Table of Contents

- How Fabric Welding Equipment Works: Principles and Core Components

- Types of Fabric Welding Technologies: Hot Air, Hot Wedge, and RF Welding

- Material Compatibility in Fabric Welding: PVC, PE, Vinyl, TPU, and Canvas

- Industrial Applications of Fabric Welding Equipment

-

Selecting and Maintaining the Right Fabric Welding Equipment

- Choosing Based on Material, Thickness, and Production Volume

- Automation, Space, and Portability Considerations

- Industry-Specific Needs: Medical vs. Construction Sector Requirements

- Routine Maintenance for Hot Air, Hot Wedge, and RF Systems

- Troubleshooting Common Issues and Extending Machine Lifespan

- FAQ